Two-step blow forming method and device for amorphous alloy special-shaped tube

An amorphous alloy, blow molding technology, applied in the field of plastic molding of amorphous alloys, can solve the problems of high cooling rate, easy to be polluted, threshold temperature limit, etc., to reduce mold costs, ensure product quality, and reduce restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

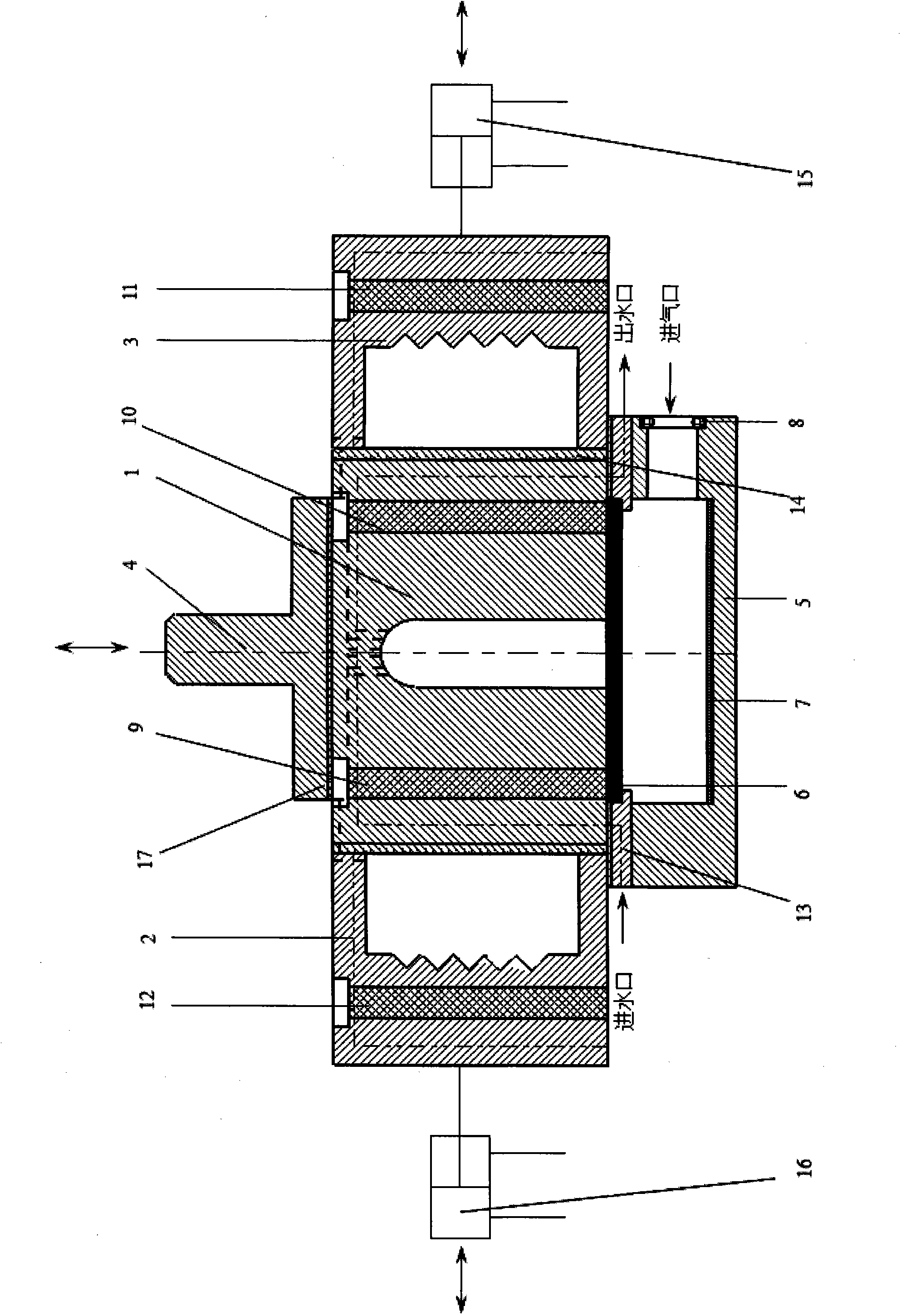

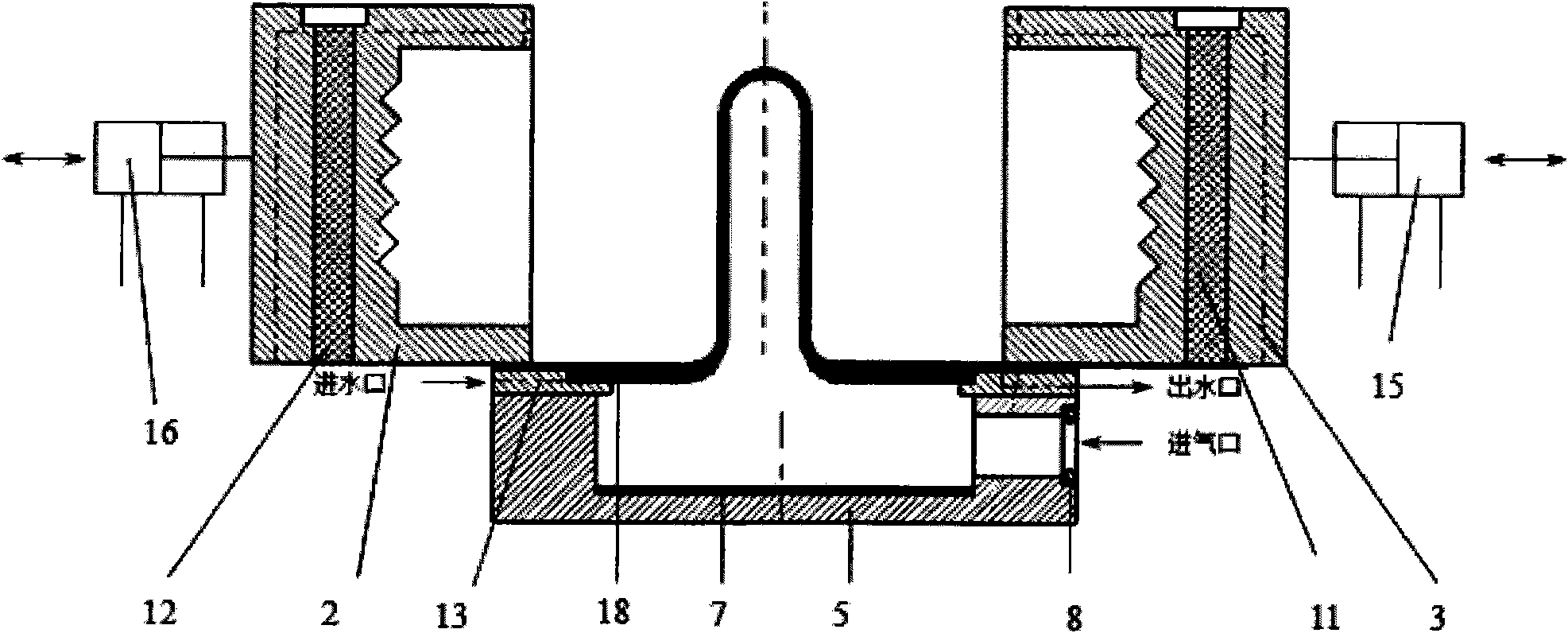

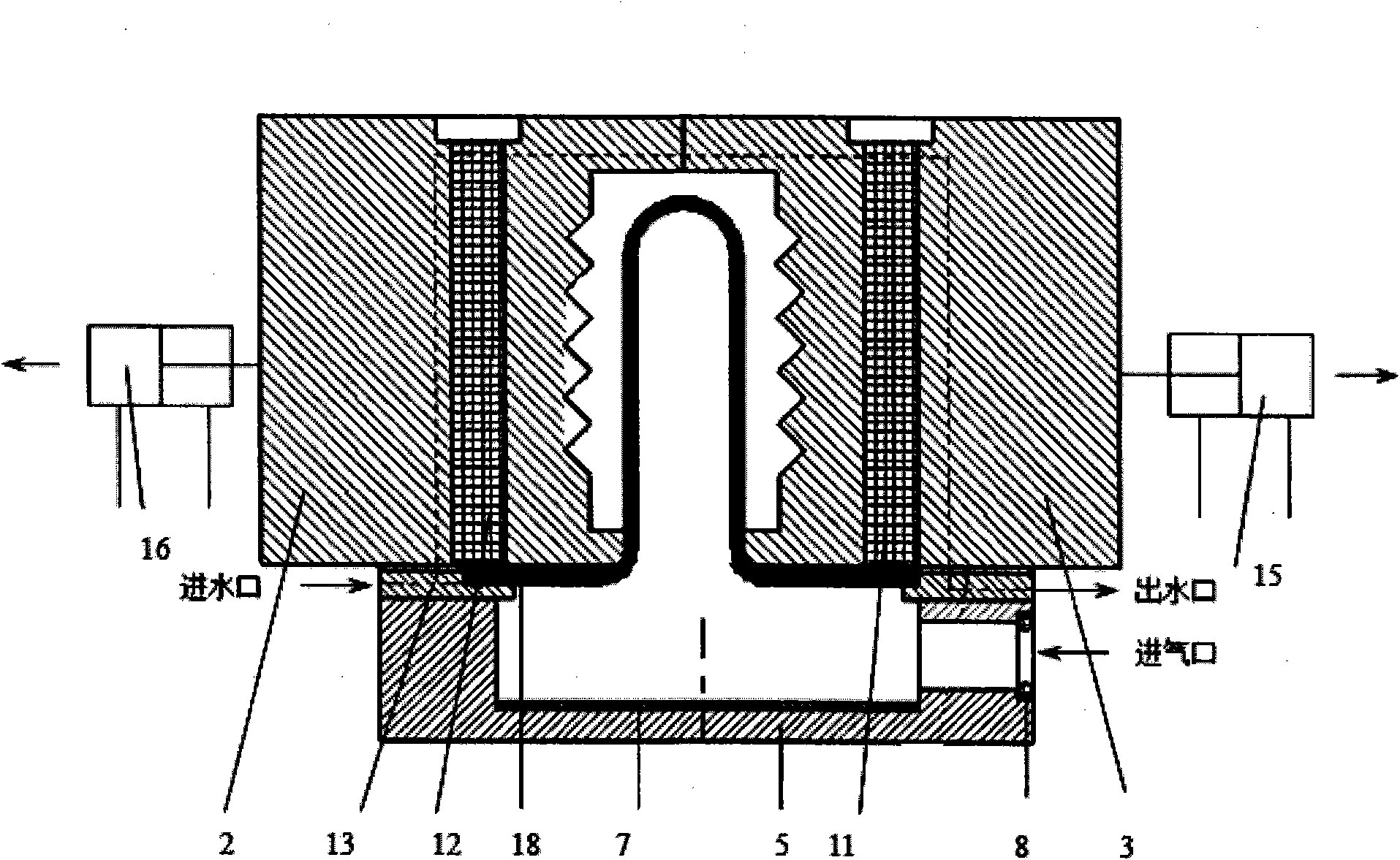

[0022] Attached below figure 1 , with Zr-based amorphous alloy (Zr 44 Ti 11 Cu 10 Ni 10 be 25 ) The two-step blow molding of special-shaped pipes is taken as an example, and the technical solution of the present invention is described in detail through the description of the embodiments.

[0023] (1) Adjust the preformed tube blank die 1 to the mold clamping state, preheat to 140°C, and keep warm; put the preformed variable thickness amorphous alloy slab 6 into the blank positioning plate 13 for accurate positioning, and then open The power switch of the infrared heating plate 7 is heated to 460°C;

[0024] (2) Open the power switch of the infrared heating lamp tube 8 on the side wall of the heating chamber 5, feed the Ar gas with a pressure of 0.2MPa, and -2 the s -1 After the pre-blow molding is carried out at a certain strain rate until the mold is completely attached, the power switch of the infrared lamp 8 is turned off, and the cooling water is passed through to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com