Stamping type granulator

A granulator and stamping technology, which is applied in the direction of stamping machines, presses, mold extrusion granulation, etc., can solve the problems of low production capacity, easy damage to bearings, inconvenient maintenance, etc., to prolong life and reduce maintenance times , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

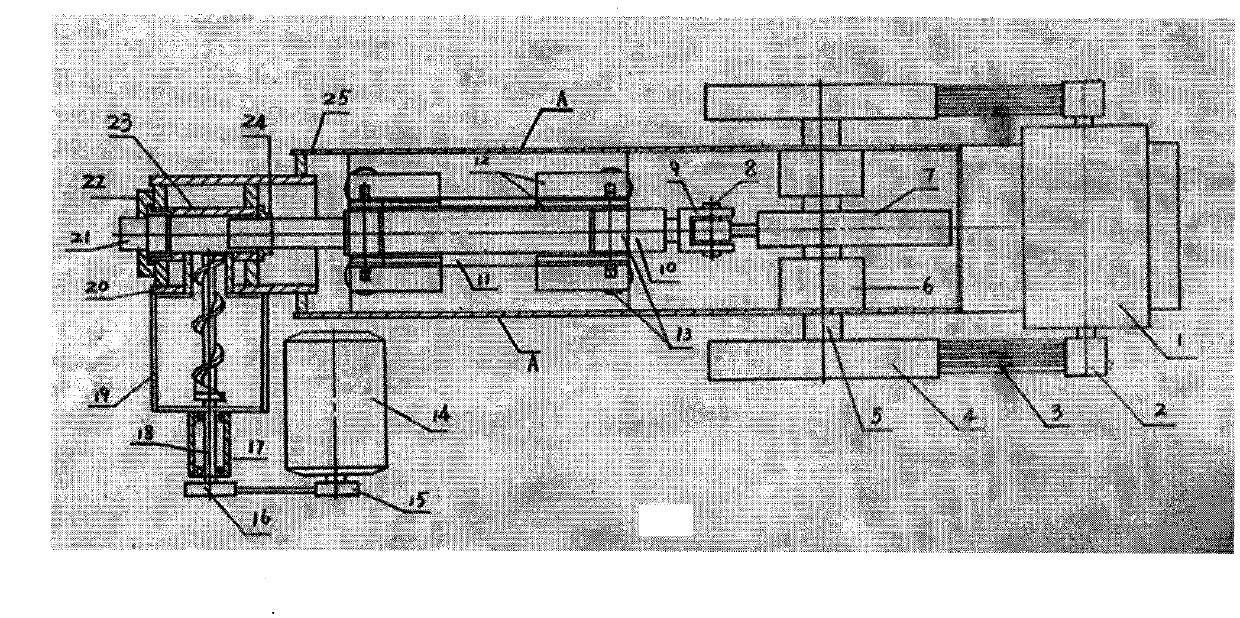

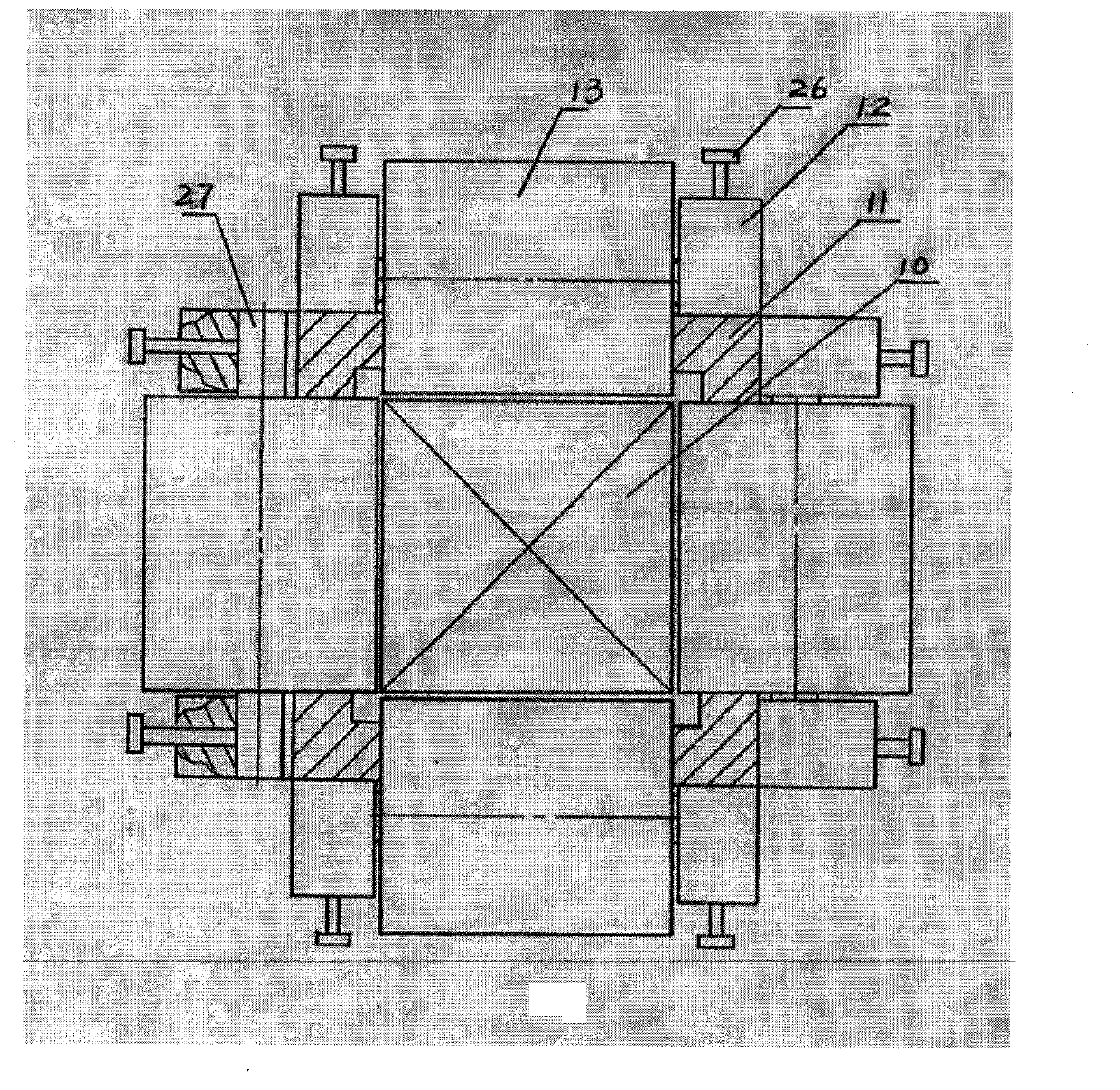

[0010] Describe embodiment in conjunction with accompanying drawing:

[0011] The belt pulleys 2 at both ends of the main motor 1 drive the V-belt 3 to rotate the large pulley 4, and drive the main shaft 5 to make the eccentric wheel 7 run, resulting in a cycle back and forth working state. The connecting rod shaft 8 connects the connecting rod base 9 and the eccentric wheel 7 to drive the stamping rod 10 to continuously stamp the material in the stamping chamber 23, so that the material is extruded from the stamping die 21 through stamping to become a rod.

[0012] The stamping seat 20 is connected with the main body frame 25 as a whole, and the stamping die cover 22 presses the stamping die 21 tightly. The cover 24 is fixed on the punching chamber 23, and when the punching rod 10 moves back and forth, the oil seal of the cover 24 seals the material in the punching chamber 23 to prevent the material from leaking out of the punching chamber.

[0013] The small pulley 15 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com