Processing technology of walnut dried tofu

A processing technology and technology of dried tofu, which is applied in cheese substitutes, dairy products, applications, etc., can solve problems such as poor taste and single taste, and achieve the effects of improving gel strength, prolonging fresh-keeping period, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The steps of the present invention are successively:

[0054] Embryo making—refrigeration—cutting embryos—brining—baking—mixing—inner packaging—sterilization—boxing and storage.

[0055] The embryo making process:

[0056] 1. Use clean and sanitized tools and utensils, and it is strictly forbidden to use them in production without disinfection.

[0057] 2. Weigh the required raw materials in advance, including soybean protein isolate, ice, water, salad oil, TG enzyme, tapioca modified starch, and walnut kernels.

[0058] 3. Pour ice and water into the chopping machine first, then add soybean protein isolate, turn on low speed for 2 minutes, then switch to high speed, chop and mix for about 6 minutes, then slowly add salad oil and rotate for about 5 minutes, finally add TG enzyme, Chop and mix cassava modified starch and walnut kernels for 1 minute, then remove the embryos and put them on a plate.

[0059] 4. Pour the cut and mixed semi-finished products into stainles...

Embodiment 2

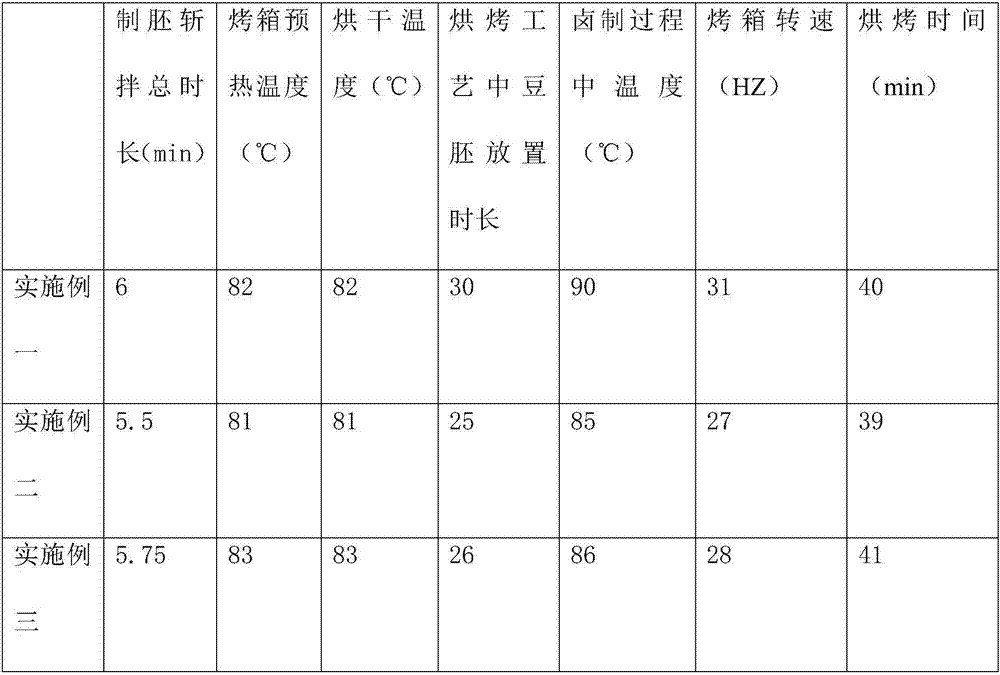

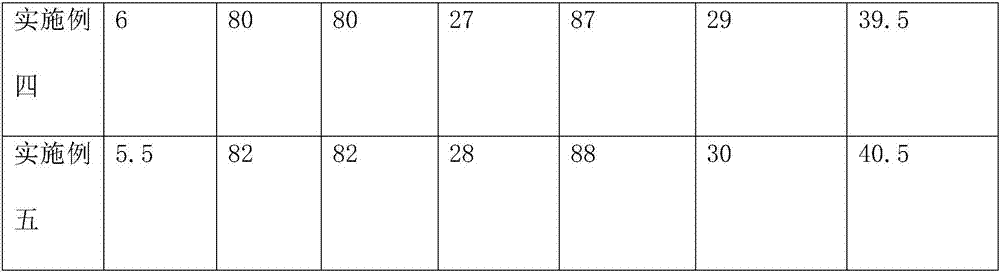

[0128] As shown in Table 1, the only difference from Example 1 is that the chopping machine rotates at low speed for 2 minutes and then switches to high speed for a total of 5.5 minutes of chopping and mixing, and then slowly adds salad oil and rotates for 6 minutes; the blanking link of the marinating process: embryo After the material is put into the pot, put 1.4 times the weight of the material water, add 300ml of dark soy sauce to marinate; close the steam valve to keep the inner wall slightly open, and maintain the temperature at 85 degrees; preheat the oven to 81 ° C, and control the drying temperature at 81 ° C. The rotating speed is controlled at 27Hz, the roasting time is kept at 39min, and the roasted bean embryos are placed for 25min.

Embodiment 3

[0130] As shown in Table 1, the only difference from Example 1 is that the chopping machine rotates at a low speed for 2 minutes and then switches to a high speed for a total of 5.75 minutes of chopping and mixing, and then slowly adds salad oil and rotates for 5.5 minutes; the blanking process of the marinating process: Put 1.4 times the weight of the raw material into the pot, add 300ml of dark soy sauce to marinate; close the steam valve to keep the inner wall slightly open, and maintain the temperature at 86 degrees; preheat the oven to 83°C, and control the drying temperature at 83°C. The speed of the oven is controlled at 28Hz, the baking time is kept at 41 minutes, and the baked bean embryos are placed for 26 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com