Magnetic nanoparticle jet flow and magnetic force working table coupling oil film forming process and device

A magnetic nanoparticle and magnetic nanotechnology, applied in the direction of grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc., can solve problems such as connection, failure to take advantage of lubrication and heat dissipation, and failure to establish the internal relationship of lubricating oil film. Achieve the effects of improving the surface quality of the workpiece, being environmentally friendly, and solving grinding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

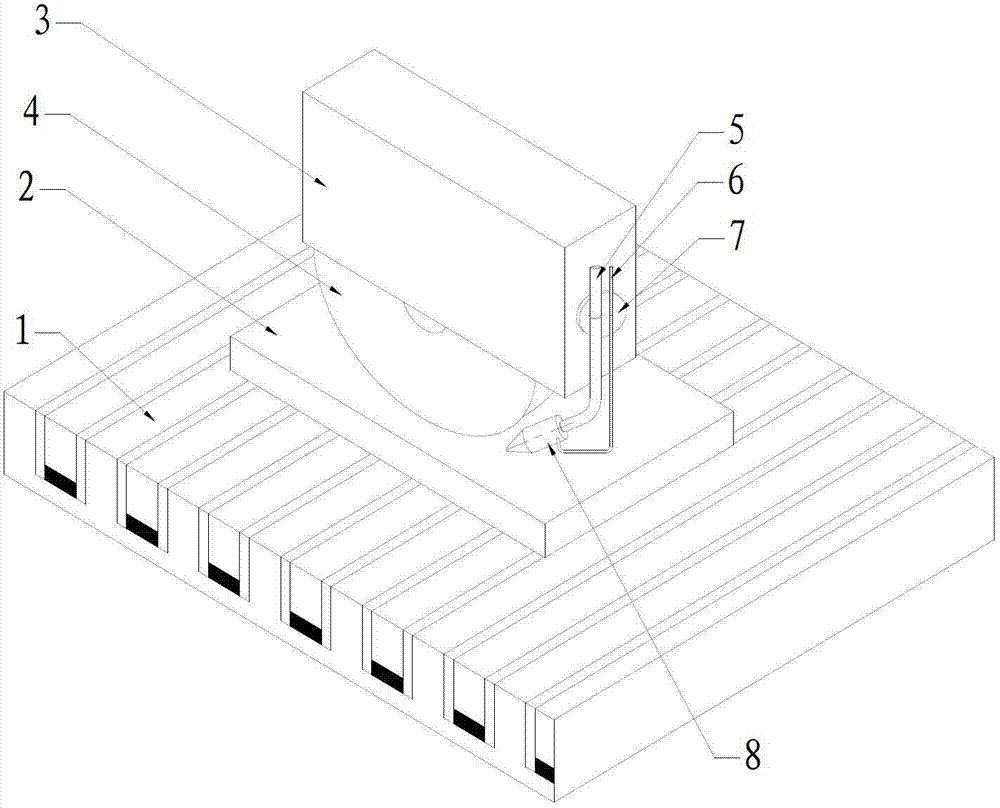

[0042] Below in conjunction with accompanying drawing, the present invention is described:

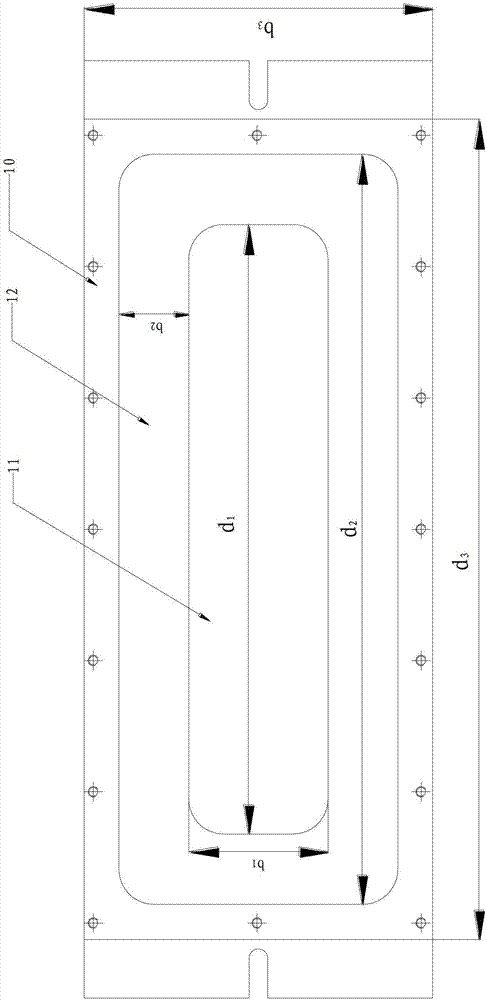

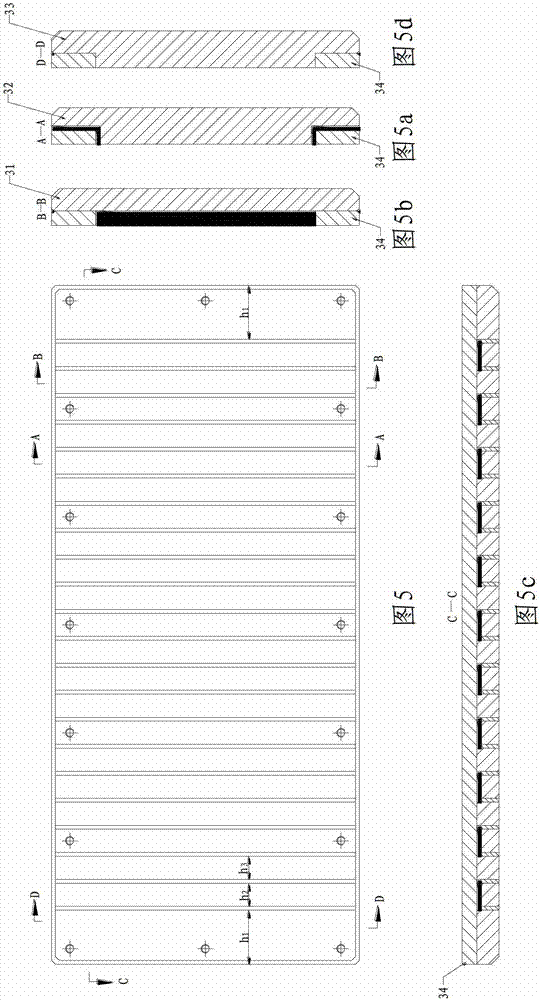

[0043] like figure 1 Shown in the general assembly axonometric drawing of this embodiment, what this embodiment described is the technology in grinding machine processing. It can be seen from the figure that there is no fixture installed on the magnetic workbench 1, and the workpiece 2 is fixed on the magnetic workbench 1 by electromagnetic attraction. The lubrication system adopts the magnetic nanofluid minimal quantity lubrication system. The magnetic nanofluid and compressed air enter the nozzle 8 through the magnetic nanofluid delivery pipe 5 and the compressed air delivery pipe 6 respectively, and form three phases after being mixed and accelerated in the nozzle 8. Stream spray (mixed spray of compressed air, solid magnetic nanoparticles and grinding fluid-based oil particles). The three-phase flow spray sprayed from the nozzle 8 will enter the grinding area between the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com