Metalworking fluid, and preparation method and application thereof

A technology of metalworking fluid and mass percentage, which is applied in the petroleum industry and lubricating compositions, etc., can solve the problems that the processing accuracy of parts cannot meet the requirements, increase the comprehensive use cost of cutting fluid, increase the amount and difficulty of waste liquid treatment, etc. , to achieve good biological stability, excellent antibacterial performance and biological stability, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

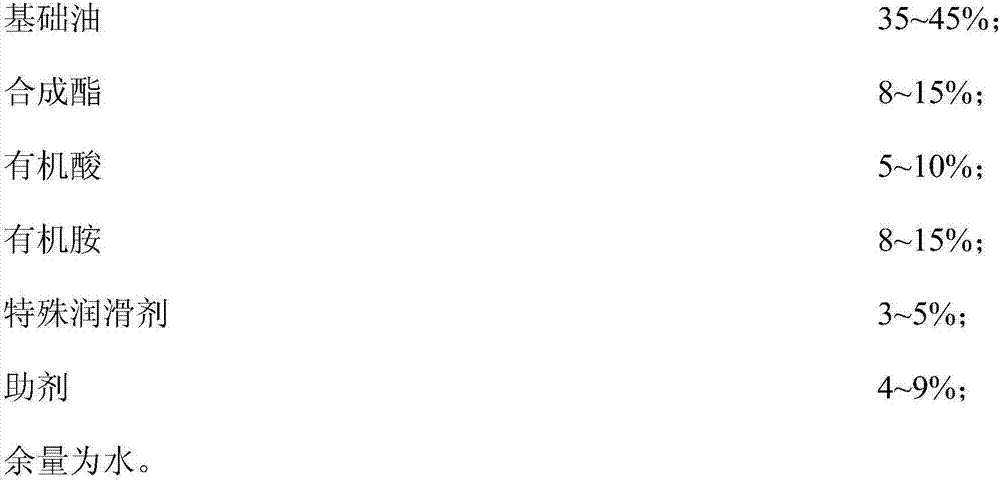

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a metalworking fluid, the method comprising the following steps:

[0047] (1) Mix 35g of iso-hexadecane, 15g of 2-ethylhexyl benzoate, 5g of organic acid, 8g of organic amine and 2g of alcohol ether carboxylic acid at 30°C for 30min under stirring at 600rpm to obtain the first mixture material;

[0048] (2) The first mixture obtained in step (1) is mixed with 26.95g water, 3g benzotriazole derivatives, 3g triethylene glycol butyl ether and 2g bactericide for 30min under stirring at 600rpm to obtain the second Mixture;

[0049] (3) The second mixture obtained in step (2) was mixed with 0.05 g of simethicone oil for 30 min under stirring at 600 rpm to obtain a metal working fluid.

[0050] Wherein, the organic acid is a mixture of ricinoleic acid, tall oleic acid and isomeric stearic acid, and the organic amine is diisopropanolamine, 2-amino-2-methylpropanol and 3-butoxy A mixture of propylamines.

Embodiment 2

[0052] A method for preparing a metalworking fluid, the method comprising the following steps:

[0053] (1) Mix 45g of isomerized hexadecane, 8g of trimethylolpropane tricaprate, 10g of organic acid, 15g of organic amine and 1g of fatty alcohol polyoxyethylene polyoxypropylene ether at 30°C under stirring at 600rpm for 30min , to obtain the first mixture;

[0054] (2) The first mixture obtained in step (1) is mixed with 10.95g water, 3g benzotriazole derivatives, 5g triethylene glycol butyl ether and 2g bactericide for 30min under stirring at 600rpm to obtain the second Mixture;

[0055] (3) The second mixture obtained in step (2) was mixed with 0.05 g of simethicone oil for 30 min under stirring at 600 rpm to obtain a metal working fluid.

[0056] Wherein, the organic acid is a mixture of talloleic acid, isomeric stearic acid and lauric acid, and the organic amine is 2-amino-2-methylpropanol, 3-butoxypropylamine and N,N - Compositions of diethylaniline.

Embodiment 3

[0058] A method for preparing a metalworking fluid, the method comprising the following steps:

[0059] (1) Mix 40g of iso-hexadecane, 10g of 2-ethylhexyl benzoate, 8g of organic acid, 12g of organic amine and 1.5g of polyisobutylene maleic anhydride at 30°C for 30min under stirring at 600rpm to obtain the first a mixture;

[0060] (2) The first mixture obtained in step (1) is mixed with 18.95g water, 4g benzotriazole derivatives, 4g triethylene glycol butyl ether and 2g bactericide for 30min under stirring at 600rpm to obtain the second Mixture;

[0061] (3) The second mixture obtained in step (2) was mixed with 0.05 g of simethicone oil for 30 min under stirring at 600 rpm to obtain a metal working fluid.

[0062] Wherein, the organic acid is a mixture of lauric acid, gluconic acid and neodecanoic acid, and the organic amine is a mixture of 3-butoxypropylamine, N,N-diethylaniline and hexamethylenetetramine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com