Processing method for automobile compressor rear cover

A technology of automobile compressor and processing method, which is applied to metal processing equipment, tools for lathes, turning equipment, etc., can solve the problems of high processing cost, low processing efficiency, complex tool cost, and achieve stable quality, The effect of high efficiency and convenient processing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

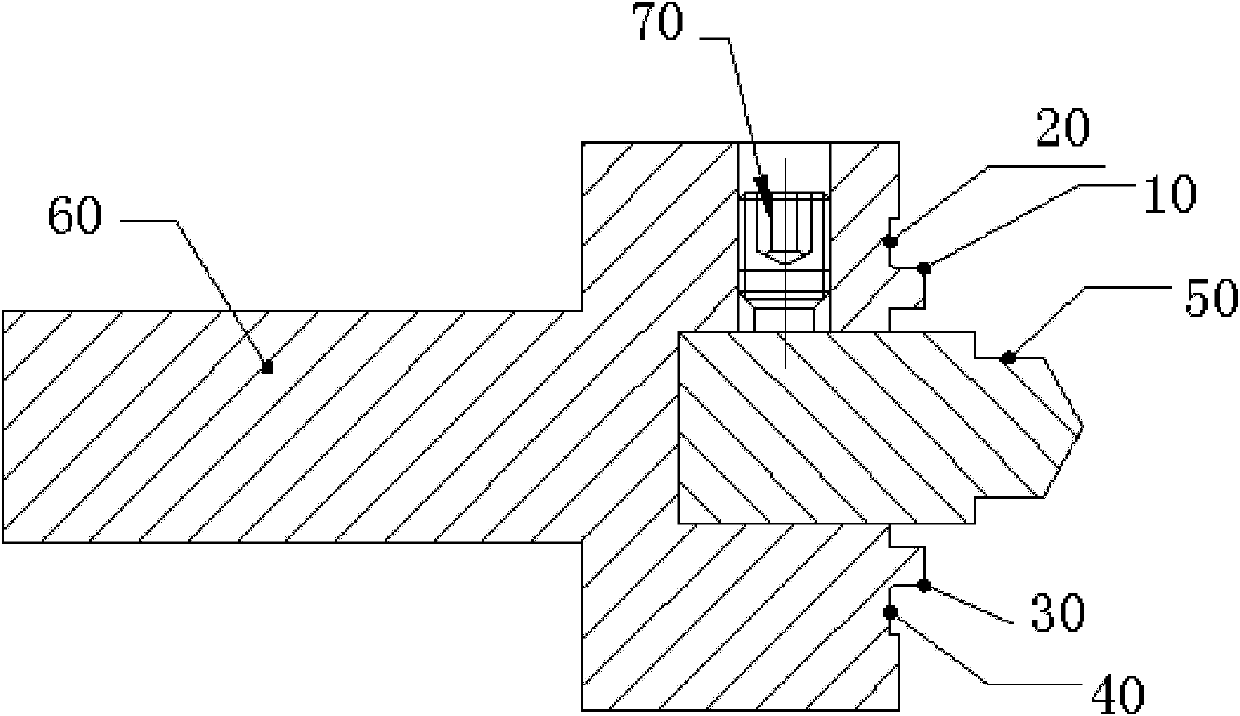

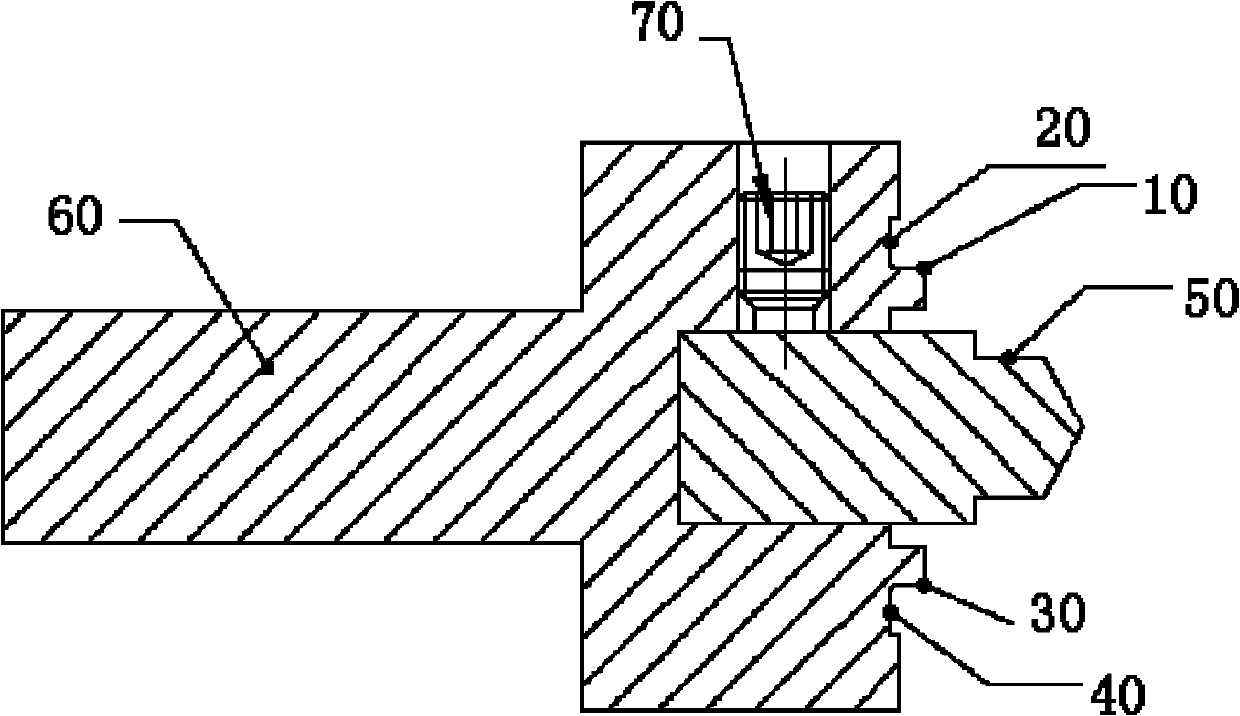

[0016] Depend on figure 2 Visible: the present invention is realized through the following steps:

[0017] design a tool;

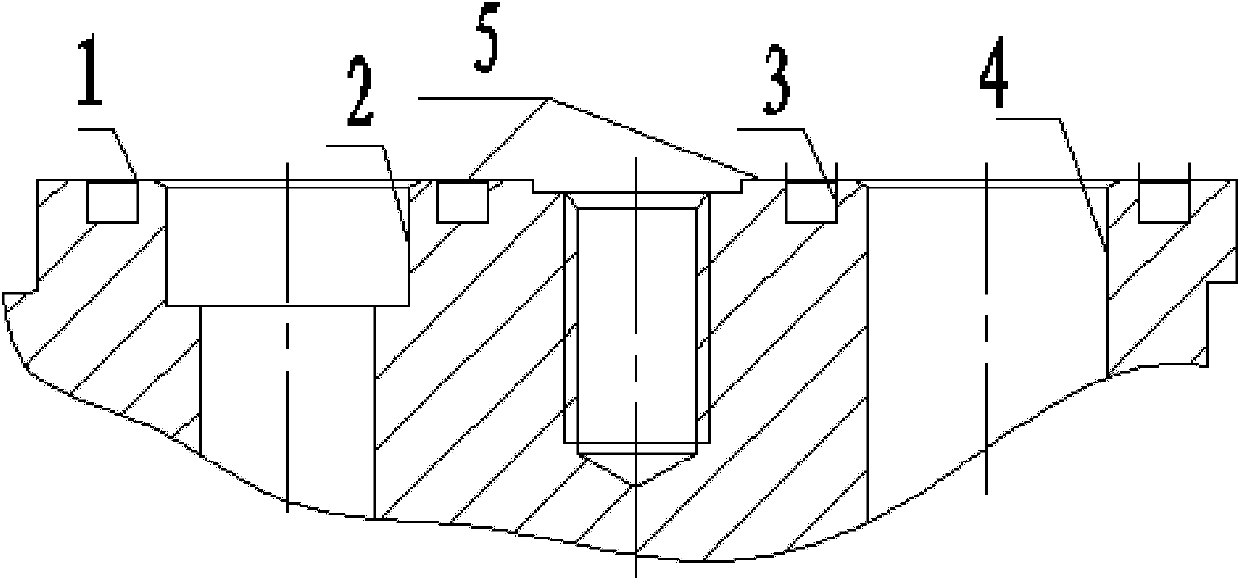

[0018] A first knife edge 10, a second knife edge 20, a third knife edge 30, a fourth knife edge 40 and a fifth knife edge 50 corresponding to the groove bottom of the back cover are set on the cutter;

[0019] During processing, the built-up edge is naturally formed at the right angle of the tool, so that the chamfer of R0.3-R0.5 is generated at the corresponding part of the back cover;

[0020] When the built-up edge reaches a certain size, it will fall off naturally due to the cutting force, and then form a new built-up edge;

[0021] Among the figure: fastening screw 70; Knife handle 60.

[0022] The internal relief angle of the tool flute is 2-6 degrees, the rake angle is 0 to -4 degrees, and the cutting edge widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com