Knife tool for processing gear ring

A cutting tool and ring gear technology, which is applied in the field of cutting tools for processing ring gears, can solve the problems of easy noise in finished products, complicated processing procedures, and high processing costs, and achieve the effects of reducing chip heat, good processing effects, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

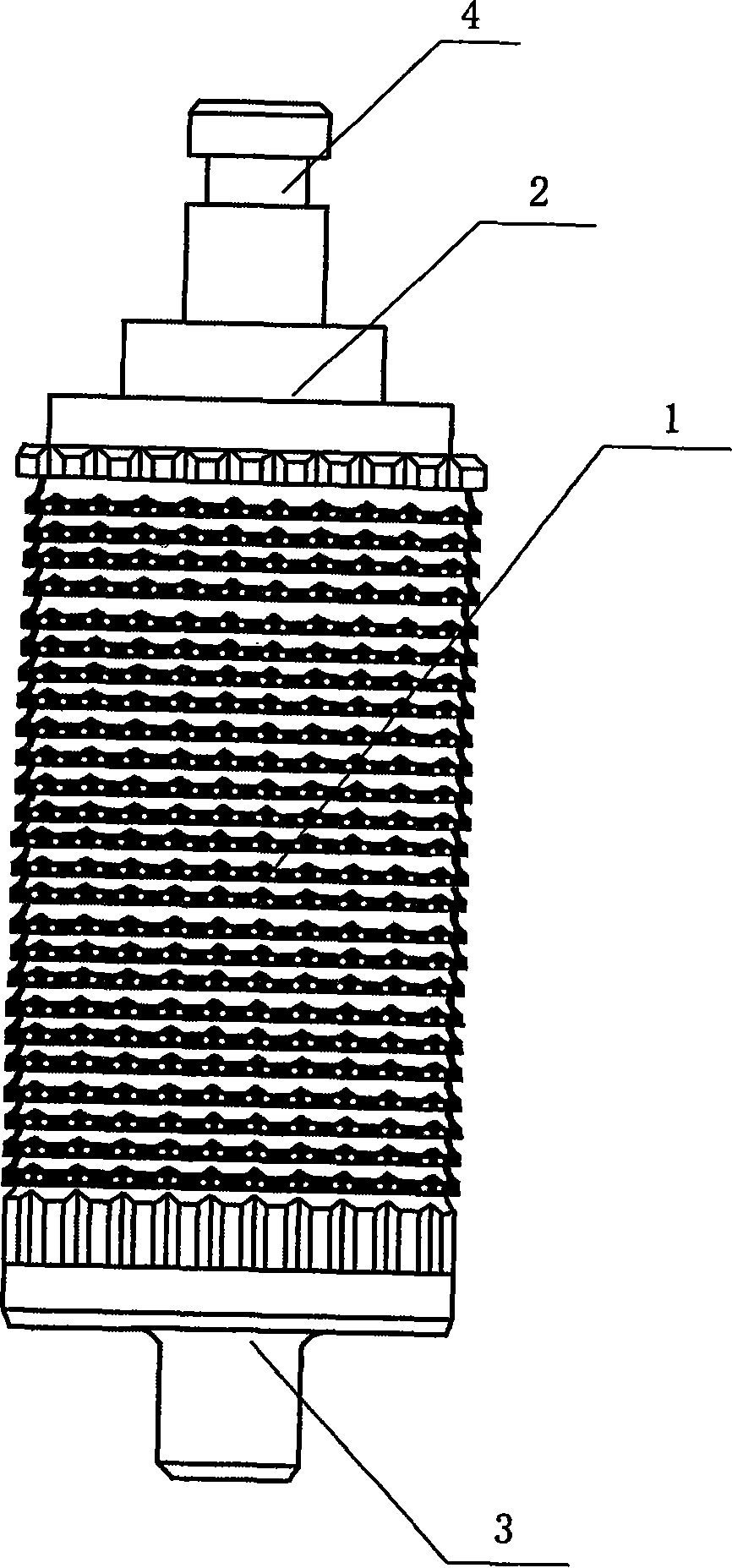

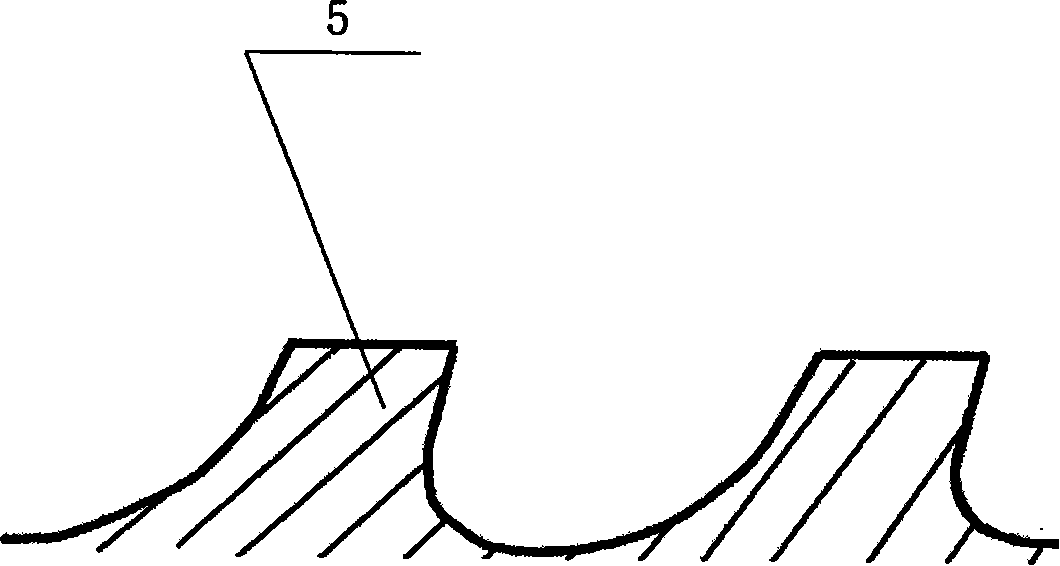

[0009] according to figure 1 with figure 2 , The present invention is a tool for processing a ring gear. It includes a cylindrical cutting part 1. The cutting part 1 is a split hierarchical structure. One end of the cutting part 1 is a front shank 2 and the other end is a rear shank 3. The cutting part 1 is an integral structure with the front handle 2 and the rear handle 3. The end of the front handle 2 is provided with a shank 4, and the surface of the cutting part 1 is distributed with multiple circles of cutter teeth 5, which are continuous spiral cutters. Tooth, tooth 5 is a 45° double-angle milling cutter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com