Preparation method of cutter surface antisticking antifriction micro mosaic composite texture

A composite weaving and micro-texturing technology, applied in the field of mechanical cutting tool manufacturing, can solve the problems of electrode wear and deformation, difficult to control the processing shape effectively, reduce friction, realize high-efficiency CNC machining, improve mold life and form Piece quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

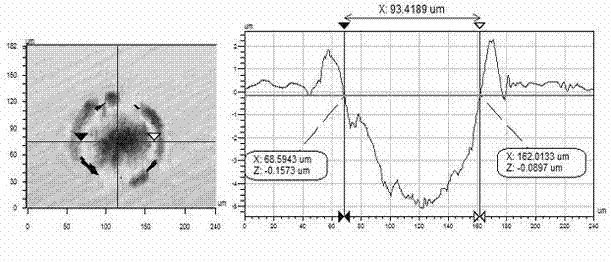

[0039] The ideal surface microcavity / microgroove texture is obtained by laser micromachining on the rake face of the high-speed steel cutting tool material, as follows figure 2 , image 3 shown. The laser wavelength used in the microcavity processing is 532nm, the current is 17 amperes, the number of pulses is 3 times, the repetition frequency is 1900Hz, and the nitrogen pressure is 0.15MPa. The laser wavelength used in the microgroove processing is 532nm, the current is 17 amperes, the scanning speed is 10mm / s, the repetition frequency is 2500Hz, and the nitrogen pressure is 0.15MPa. After ultrasonic cleaning, the dimensions of microcavity and microgroove measured by VYKO morphology instrument are as follows: Figure 4 and Figure 5 As shown, it shows that the micro-texture processing quality is good, which creates good conditions for the embedding of solid lubricants. Through uniform mixing-powder drying-surface pretreatment-press filling solidified lubricant-surface po...

Embodiment 2

[0043] Through laser micromachining on the rake face of YT15 cemented carbide tool material, the surface texture obtained is as follows: Figure 10 shown. The laser wavelength used in the microcavity processing is 532nm, the current is 17 amperes, the number of pulses is 4 times, the repetition frequency is 1900Hz, and the nitrogen pressure is 0.15MPa. After ultrasonic cleaning, the microcavity size measured by VYKO morphology instrument is as follows: Figure 11 shown. Hard textured bumps about 2 microns high formed around the cavity. Through uniform mixing-powder drying-surface pretreatment-press filling solidified lubricant-surface post-treatment and other processes, the solid lubricant can be uniformly filled and pressed, and the embedded filling effect can be achieved. Figure 12 As shown, the lubricant in the microcavity is basically flush with the surface of the specimen, indicating that the embedding effect is good.

Embodiment 3

[0045] By laser micromachining the rake face of titanium nitride-coated tool material, the surface texture such as Figure 13 shown. The laser wavelength used in the microcavity processing is 532nm, the current is 17 amperes, the number of pulses is 6 times, the repetition frequency is 1900Hz, and the nitrogen pressure is 0.15MPa. After ultrasonic cleaning, the microcavity size measured by VYKO morphology instrument is as follows: Figure 14 shown. Due to the coating, no wear-resistant textured bumps were produced around the cavities. Therefore, the tool surface roughening and microcavity / groove composite texture treatment can be carried out before the tool is coated. The composite texture processing before coating can improve the efficiency of laser micromachining. The method of texture first and then coating can effectively prevent the side effect of laser processing on the tool coating, and can improve the wear resistance of the textured convex surface. Then through un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com