Laser compound strengthening technology

A laser shock strengthening and laser technology, which is applied in the coating process of metal materials, manufacturing tools, coatings, etc., can solve the problems of chemical diffusion wear, accumulated tumor scales, high temperature deformation resistance of nickel-based alloys, etc., to improve Stability, extended tool life, and improved residual compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

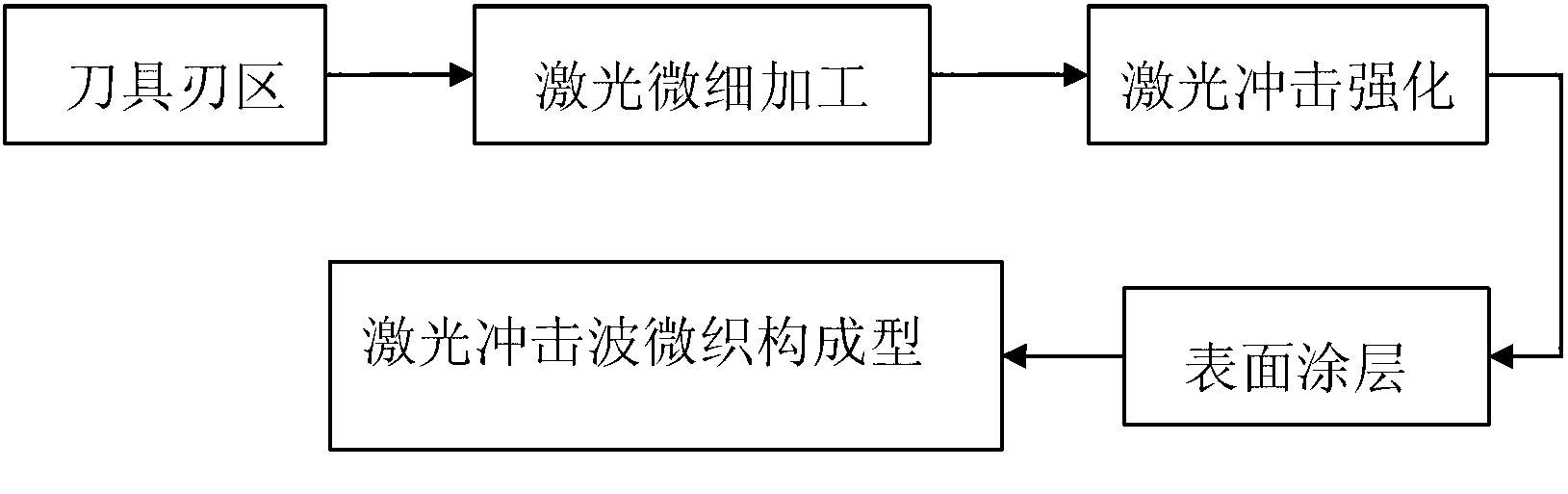

[0012] In order to better illustrate the structure and implementation details of the present invention, the implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the laser composite strengthening process of the present invention includes:

[0014] (1) Femtosecond laser micromachining is performed on the edge area of the cemented carbide tool before coating preparation to obtain pits arranged in a certain order. Through the micro-texture formed on the surface interface of the tool, the wetting characteristics and transmission of the edge area of the tool are significantly improved. Heat, cooling, lubrication conditions, and the steep femtosecond laser microtopography on the surface of the substrate form a bonding strengthening mechanism at the interface to improve the interface bonding strength.

[0015] (2) Laser shock strengthening is carried out in the edge area to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com