Lightweight projectile resistant armor system with surface enhancement

a projectile-resistant, armor-enhancing technology, applied in the field of armor systems, can solve the problems of penetration damage and blunting, and achieve the effects of increasing the armor protection effect, significant ballistic performance improvement, and facilitating energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

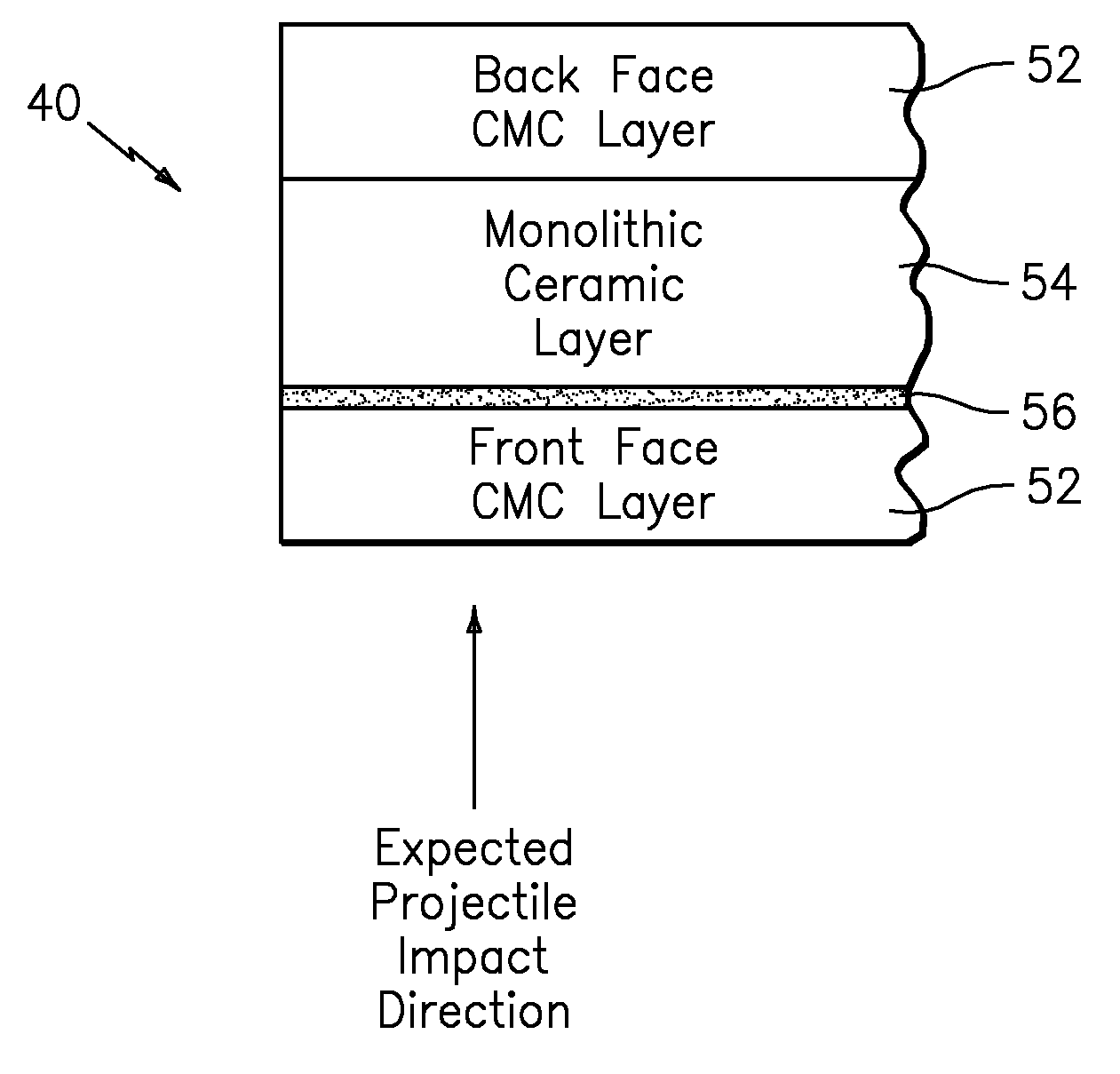

[0014]Referring to FIG. 1, an armor system 30 includes an armored panel 32 which is manufactured as a layered structure having a multiple materials some of which maybe bonded together. The armored panel 32 generally includes a front face layer 38 (optional), a hard ballistic material layer 40, a compressed oriented fiber spall shield layer 42, a spacer layer 44 (optional) and a backing layer 46 (optional). In one disclosed embodiment, the front face layer 38 is approximately 0.02 inches thick, the hard ballistic material layer 40 is approximately 0.35 inches thick, the compressed oriented fiber spall shield layer 42 is approximately 0.5 inches thick, the spacer layer 44 is approximately 0.22 inches thick, and the backing layer 46 is approximately 0.09 inches thick.

[0015]The front face layer 38 and the backing layer 46 are preferably manufactured from a polymer matrix composite glass fabric cloth such as fiberglass, S-2 Glass, IM Graphite, Low Mod Graphite, Kevlar or the like which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com