Self-lubricating-type ultrasonic rolling device with micro-array structure on tool head

A microarray structure, ultrasonic rolling technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of inability to meet the production requirements of workpieces, weakened ultrasonic vibration impact effect, and small ultrasonic impact amplitude. The effect of reducing processing cost, improving lubricating state, and improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

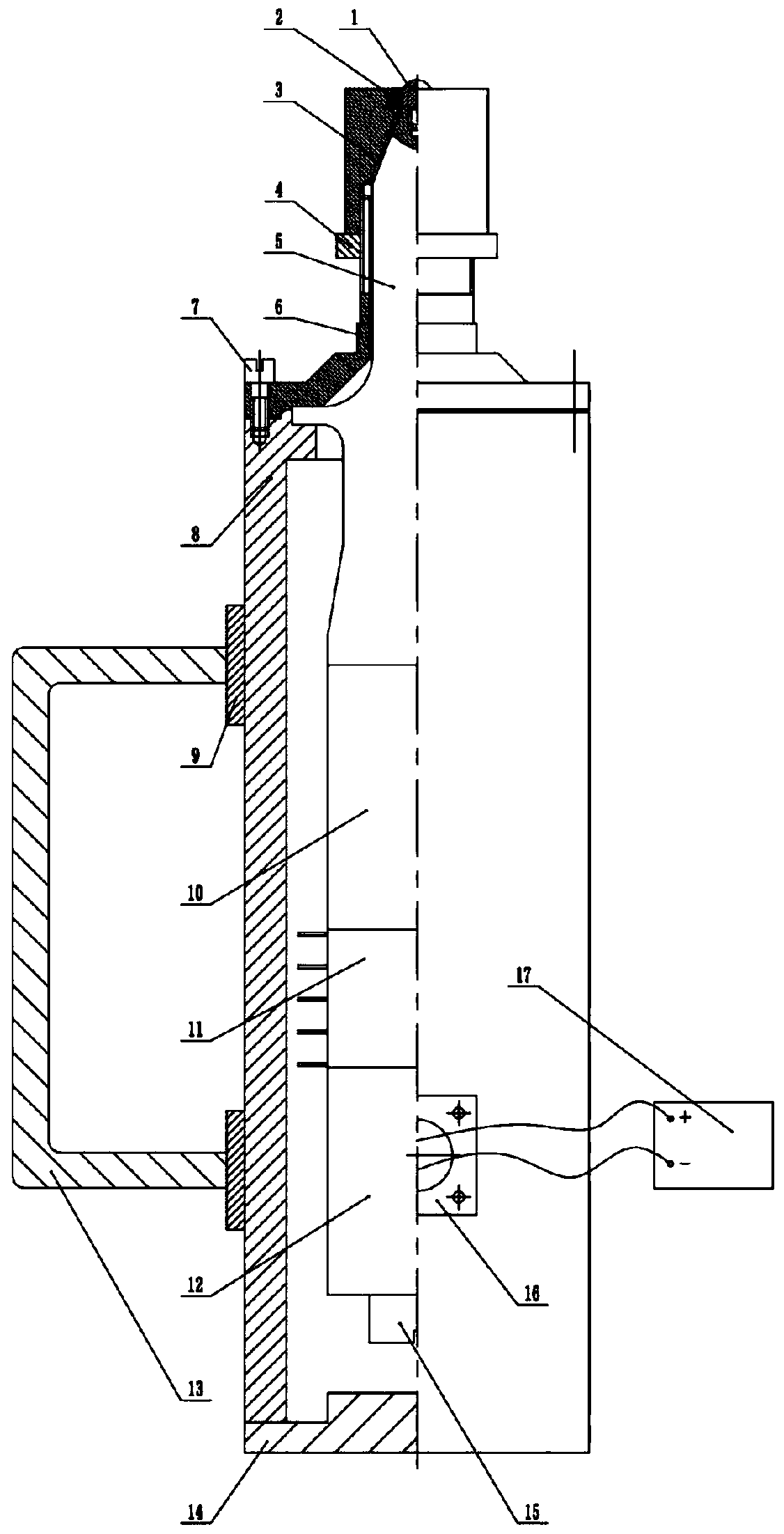

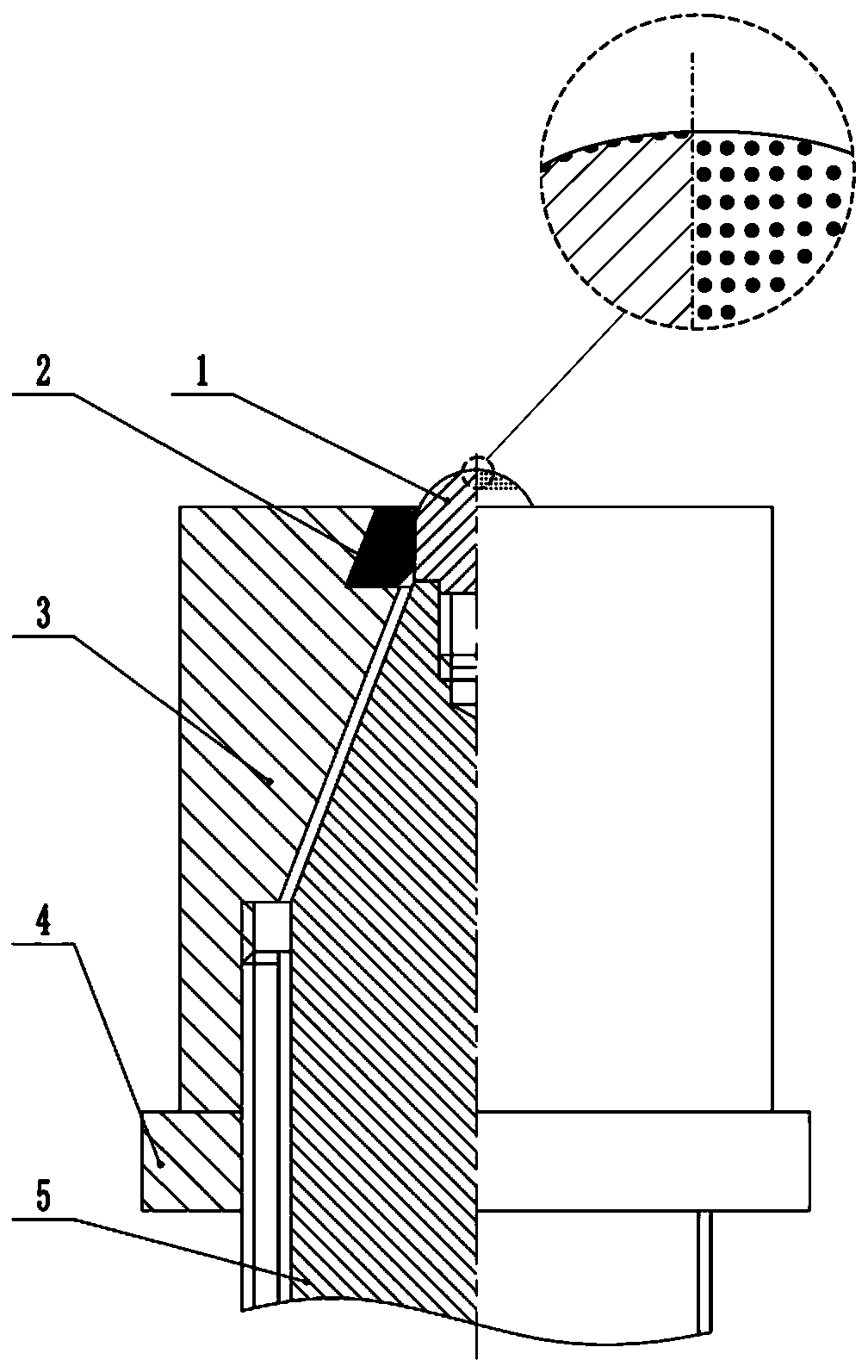

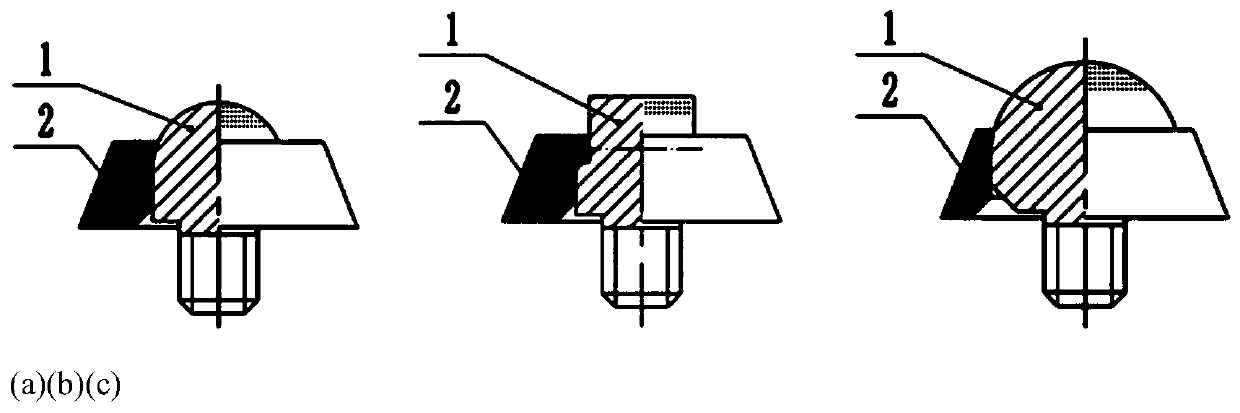

[0020] The self-lubricating ultrasonic rolling device with a microarray structure on the tool head of the present invention, before performing ultrasonic rolling processing, firstly, according to the size and material of the workpiece, image 3 Choose the appropriate model from the various integrated microarray structure rolling heads shown. After the assembly of the ultrasonic rolling device is completed, it is fixed on the tool rest of the CNC machine tool through the connecting handle 13 . Turn on the hydraulic pump, the coolant is introduced from the oil inlet at the lower end of the front positioning cylinder 6, and gradually fills the cavity formed by the outer cylinder 3 of the tool head and the horn 5, and flows out from the front end of the rolling head 1 to cool and lubricate the rolling The contact surface between the head 1 and the workpiece and the rolling head support 2, and then the excess coolant is led out from the oil outlet at the upper end of the front posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com