Drawing die

A drawing die and die technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of easy generation of built-up edge, affect the quality of steel shell, reduce production efficiency, etc., to extend the continuous operation time, The effect of improving deposition phenomenon and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

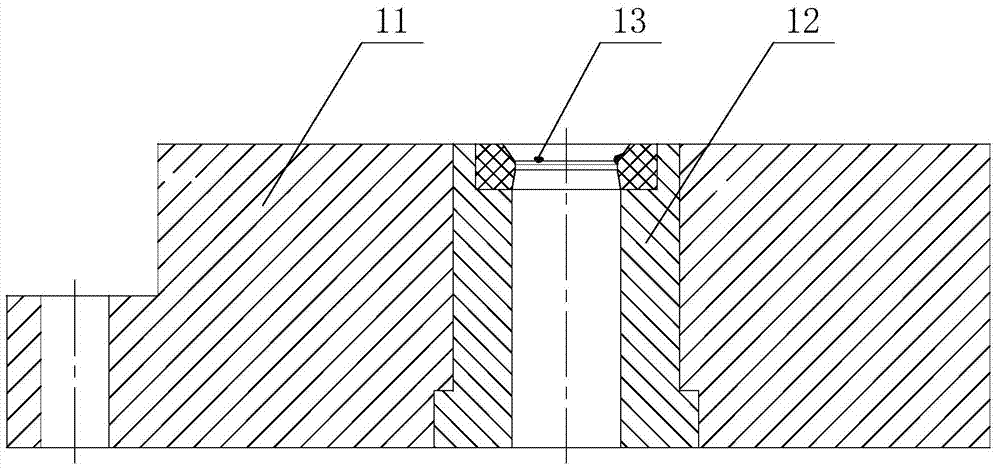

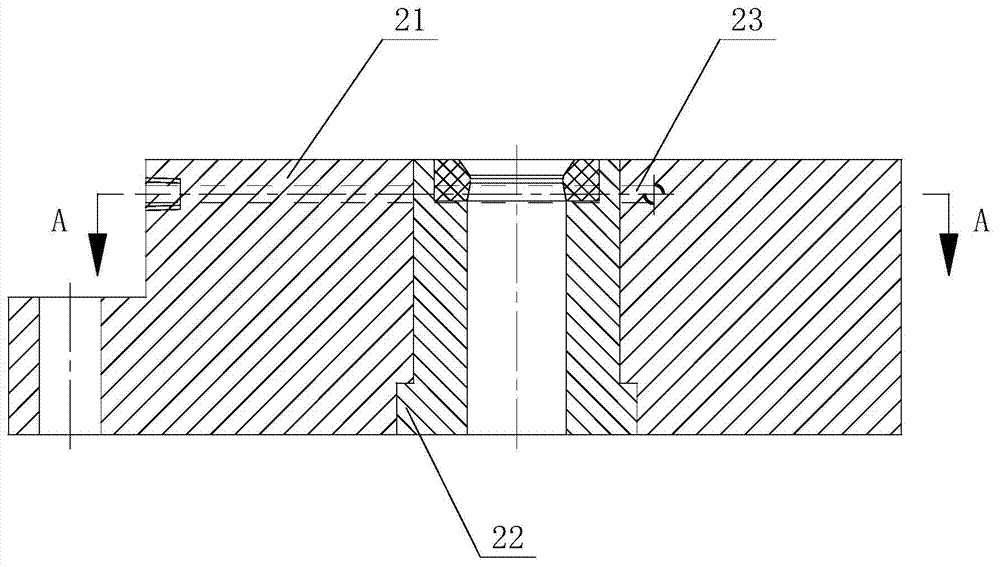

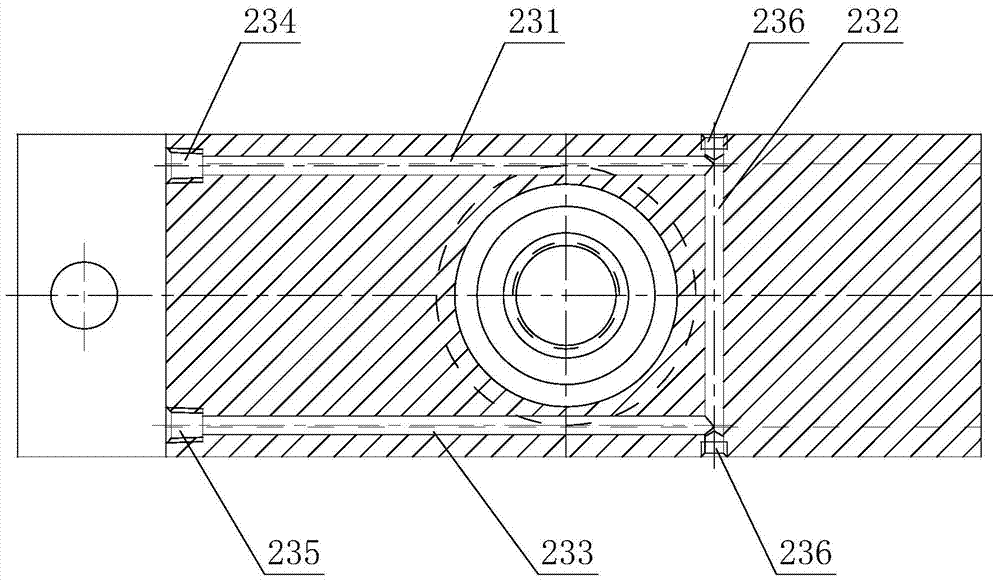

[0018] Please refer to figure 2 and image 3 as shown, figure 2 It is a structural schematic diagram of a stretching die of the present invention; image 3 yes figure 2 A schematic cross-sectional view of a stretching die at A-A is shown. In this embodiment, a drawing die includes a die base 21 and a die 22 disposed in the die base 21, a cooling channel 23 is opened on the die base 21, and the cooling channel 23 is arranged on At the periphery of the mouth of the die 22, the cooling channel 23 includes a liquid inlet pipe 231 and a liquid outlet pipe 233 parallel to each other. One end of the liquid inlet pipe 231 is provided with a liquid inlet 234, and the other end is connected to the connecting pipe. 232 connected, one end of the liquid outlet pipe 233 has a liquid outlet 235, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com