Double-face groove profile cutting blade

A technology of cutting inserts and double-sided grooves, which is applied in turning equipment, accessories of tool holders, and tools used in lathes, etc., can solve the problem that built-up edge cannot be effectively suppressed, the sharpness and stability of a single blade, and the processing Surface chip plastic deformation and other problems, to avoid work hardening and plastic deformation of chips, prevent damage, reduce abnormal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

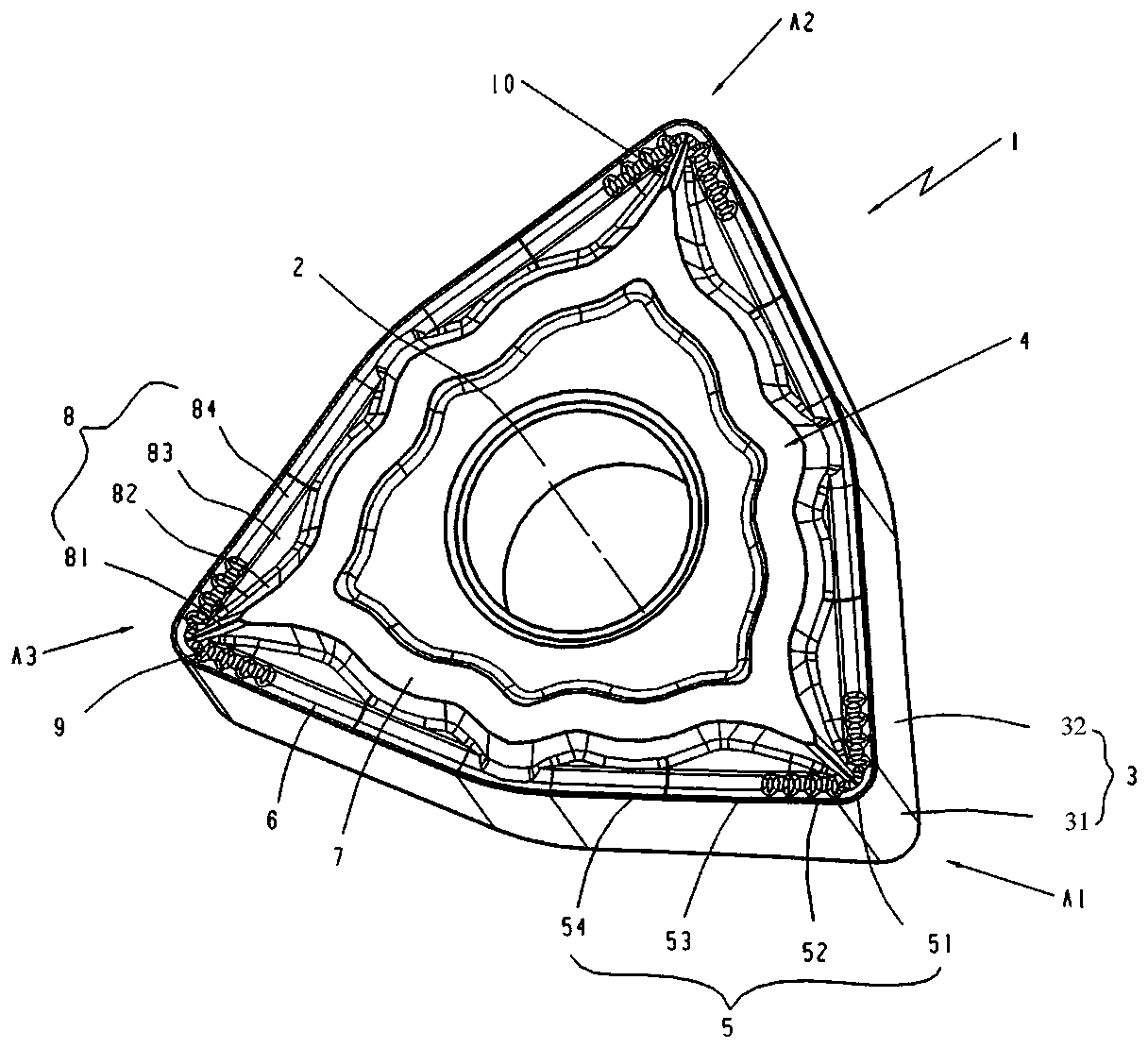

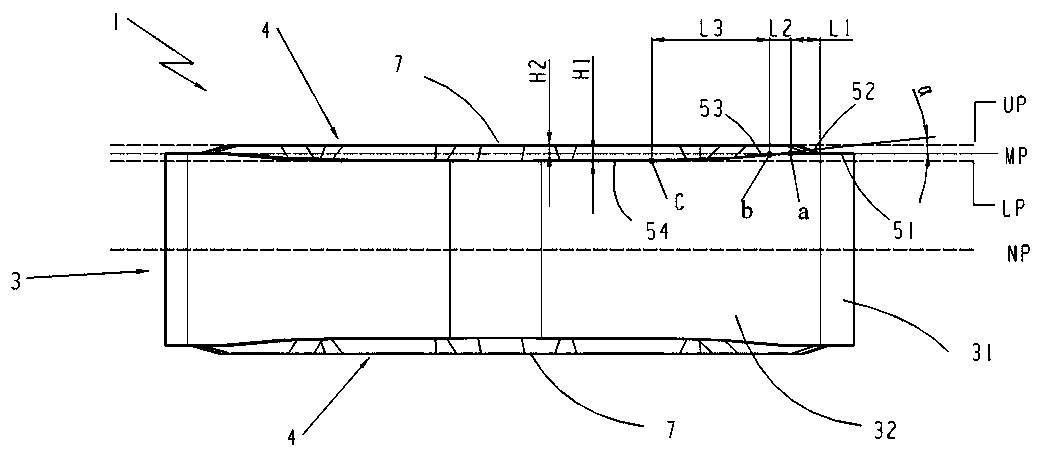

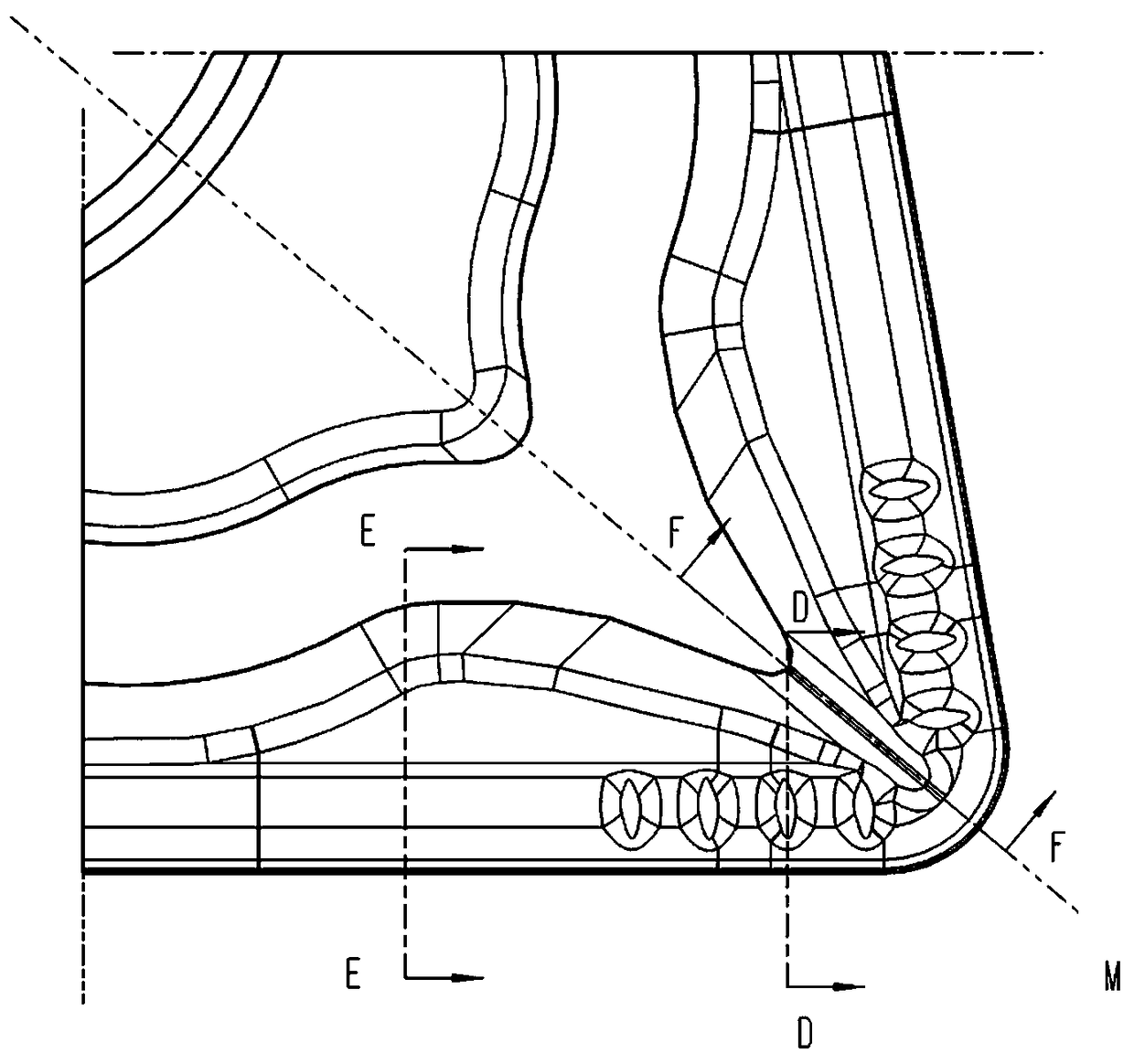

[0033] Such as figure 1 As shown, a double-sided groove type cutting insert, the above-mentioned insert body 1 is a geometric structure with a polygonal up-and-down symmetrical arrangement, the insert body 1 is provided with a insert positioning hole 3 located at the geometric center, and the above-mentioned insert body 1 consists of an upper end surface, The lower end surface 4, a plurality of side surfaces 32 connecting the upper surface and the lower surface 4, and the arc side surface 31 between two adjacent side surfaces 32, in this embodiment, the blade body 1 is approximately equilateral Geometric structure of equiangular hexagonal body symmetrically set up and down. Both the upper end surface and the lower end surface 4 are provided with a support surface 7 along the edge of the chip breaker 10 and between the positioning hole 2. The support surface 7 is the highest plane of the upper end surface 4 and is close to the side of the cutting guide surface 8. The second cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com