Coating blade for steel component processing and preparing method thereof

A technology for coating blades and steel parts, which is applied in metal processing equipment, coatings, metal material coating processes, etc., can solve problems such as built-up edge and crater wear of coated blades, and achieve sharpness and fineness Grain size, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a coated blade for steel processing, comprising the following steps:

[0035] S1. Weigh Co, TaNb8, (W, Ti) CN and WC respectively, wherein the mass fraction of Co is 6.8%, the mass fraction of TaNb8 is 3%, (W, Ti) CN mass fraction is 5.1%, and the balance is WC;

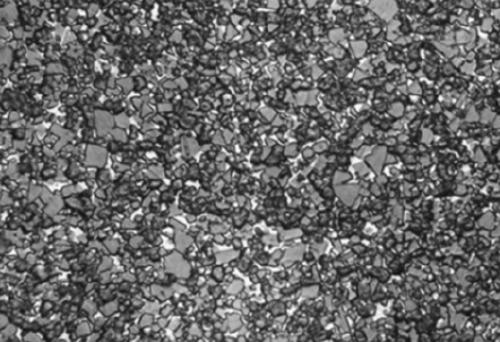

[0036] S2. Mix the raw material weighed in step S1 with polyethylene glycol, the amount of polyethylene glycol is 2% of the mass of the raw material, pour it into a drum type ball mill for ball milling, the ball milling time is 24 hours, and the ball milling medium is alcohol;

[0037] S3. Dry, press, and sinter the mixture treated in step S2 to make a cemented carbide matrix blade. The sintering process is as follows: put the material in a sintering furnace with a hydrogen atmosphere, and heat up from 25°C to 180°C at a uniform speed in the first 30 minutes. Then the temperature was raised to 310°C at a constant speed for 30 minutes, then to 370°C at a constant...

Embodiment 2

[0040] This embodiment provides a method for preparing a coated blade for steel processing, comprising the following steps:

[0041] S1. Weigh Co, TaNb8, (W, Ti) CN and WC respectively, wherein the mass fraction of Co is 6.8%, the mass fraction of TaNb8 is 3%, (W, Ti) CN mass fraction is 5.1%, and the balance is WC;

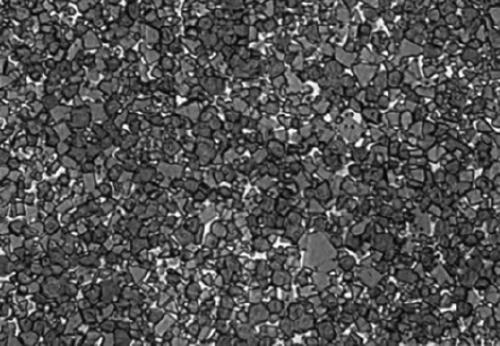

[0042] S2. Mix the raw material weighed in step S1 with polyethylene glycol, the amount of polyethylene glycol is 2% of the mass of the raw material, pour it into a drum-type ball mill for ball milling, the ball milling time is 15 hours, and the ball milling medium is alcohol;

[0043]S3. Dry, press, and sinter the mixture treated in step S2 to make a cemented carbide matrix blade. The sintering process is as follows: put the material in a sintering furnace with a hydrogen atmosphere, and heat up from 25°C to 180°C at a uniform speed in the first 30 minutes. Then the temperature was raised to 310°C at a constant speed for 30 minutes, then to 370°C at a constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com