Guiding sliding friction pair of multi-element composite texture, processing method and application of guiding sliding friction pair

A guided sliding, multi-component composite technology, applied in the field of friction pair self-lubrication, can solve the problems of increasing manufacturing cost and operation difficulty, easy peeling of coating, affecting the lasting stability of lubrication, etc. The effect of the uniform coefficient of dynamic and static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

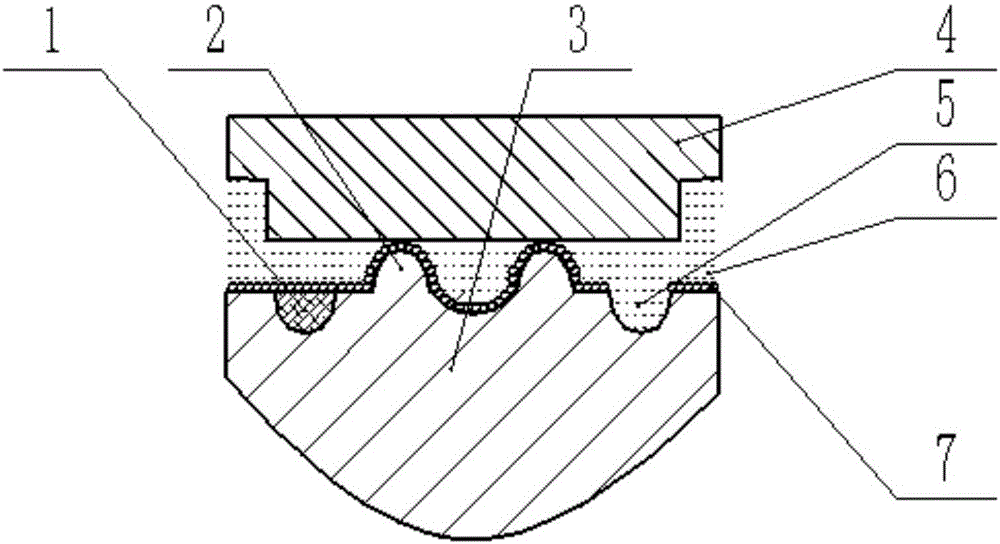

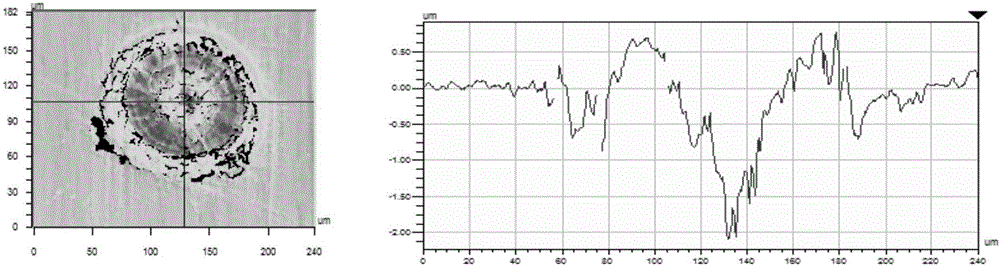

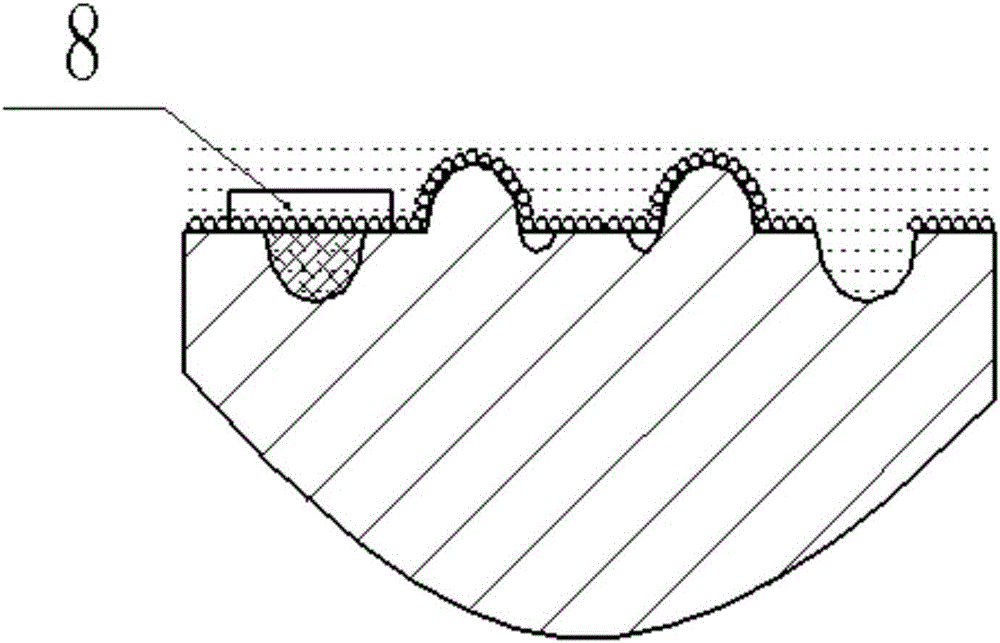

[0045] Step 1: First, perform laser surface micro-texture processing, and then use a polishing machine to polish the surface of the guide rail substrate to ensure that the slag and flash on the surface of the substrate are completely removed. Use YLP-HP-1-100-100-100 fiber laser to process laser surface microtexture on the surface of the friction pair. The laser wavelength is 1064nm, the pulse width is 50-500ns, the laser power is 20-150W, and the laser pulse is repeated. The frequency is 10-100kHz, the duration of the laser to texture a single micro-pit 5 is 0.1-0.5ms or the diode-pumped solid-state light source (DPSS) YAG laser is used for laser surface micro-texture processing, and the focal length of the focusing lens is 50-100mm , the repetition frequency is 6.5-9.5khz, the laser wavelength is 532nm or 1064nm, the current intensity is 12-22A, the scanning speed is 4-16mm / s, and the auxiliary gas uses 99.9% N 2 , the pressure is 0.1-0.4Mpa. The micro-pit 5 is processed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com