Micro-texture ZrVSiN self-adaptive coated cutting tool and preparation process thereof

An adaptive, micro-textured technology, applied in metal material coating process, coating, superimposed layer plating, etc., can solve the problems of low energy density of femtosecond laser, high processing cost, long processing time, etc., to achieve Effects of high hardness, improved service life, improved hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

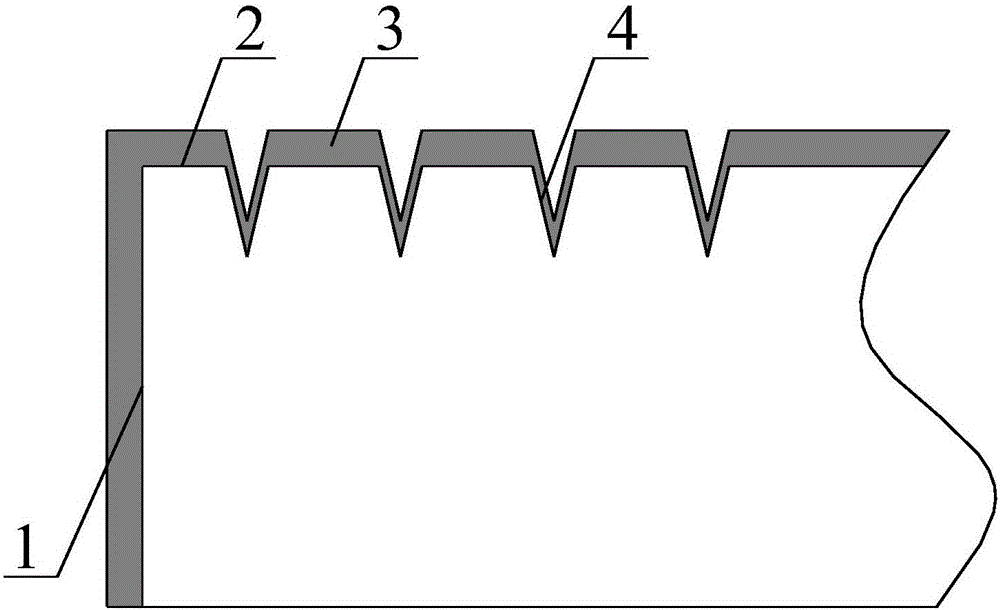

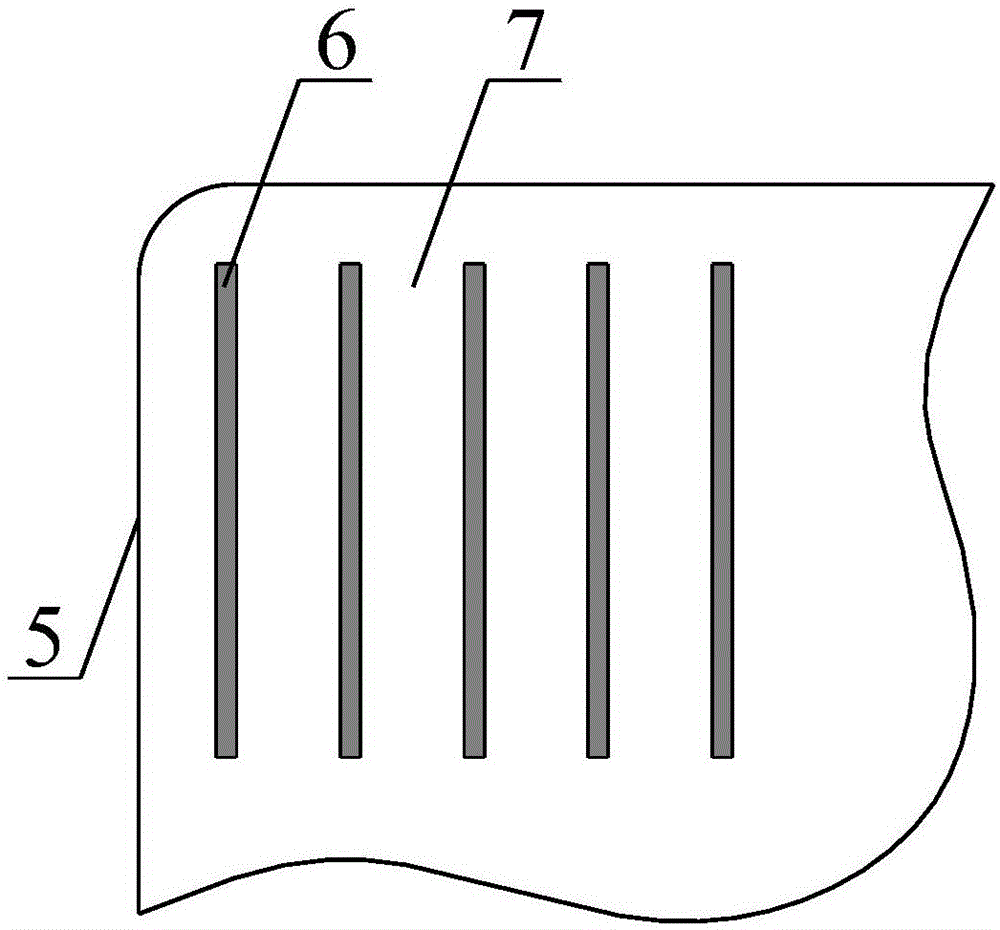

[0031] Micro-textured ZrVSiN adaptive coating tool, the tool base material is Al 2 O 3 Based on ceramic turning tools, the tool rake face matrix is processed with micron texture, and the surface coating of the tool is ZrVSiN adaptive coating and Zr transition layer from top to bottom.

[0032] Micro-texture ZrVSiN adaptive coating tool and its preparation process. First, Nd:YAG nanosecond laser is used to process micro-texture on the tool rake face, and then multi-arc ion plating + intermediate frequency magnetron sputtering technology is used to deposit Zr on the tool surface The transition layer, ZrVSiN adaptive coating; the atomic percentage of V element in the ZrV alloy target is between 40at.%, by adjusting the N 2 Flow rate, Si target target current and ZrV alloy target target current make the atomic percentage of Si element in the ZrVSiN coating between 3-10 at.%, and the atomic percentage ratio of Zr to V element between 0.5-1.5.

[0033] The specific preparation process s...

Embodiment 2

[0044] Micro-texture ZrVSiN self-adaptive coating tool, tool base material YS8 hard alloy turning tool, micro-texture is machined on the tool rake surface substrate, and the tool surface coating is ZrVSiN self-adaptive coating and Zr transition from top to bottom Floor.

[0045] Micro-texture ZrVSiN adaptive coating tool and its preparation process. Firstly, Nd:YAG nanosecond laser is used to process micro-texture on the tool rake face, and then multi-arc ion plating + intermediate frequency magnetron sputtering technology is used to deposit Zr on the tool surface Transition layer, ZrVSiN adaptive coating; the atomic percentage of V element in the ZrV alloy target is between 60at.%, by adjusting the N 2 The flow rate, Si target current and ZrV alloy target current make the atomic percentage of Si element in the ZrVSiN coating between 3-10 at.%, and the atomic percentage ratio of Zr to V element between 0.5-1.5.

[0046] The specific preparation process steps of the micro-textured Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com