Wave-absorbing foam concrete and preparation method for

A technology of foam concrete and wave absorbing agent, which is applied in the interdisciplinary field of building material science and electromagnetic science, can solve the problems of high cost, high density of wave absorbing materials, and inability to take into account thermal insulation performance, etc., and achieve low cost, wide absorption frequency band, and thermal insulation good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] ① Mix 180g of micron carbonyl iron powder with 1620g of sulphoaluminate cement and stir evenly to obtain material I.

[0031] ②Mix 18g of animal and plant protein foaming agent with 126g of water, make foam for 3 minutes, and obtain foam;

[0032] ③ Mix material I, polycarboxylate high-efficiency water reducer and 770g water, and stir evenly to obtain a slurry;

[0033] ④ Add the foam to the slurry to mix, and stir evenly to obtain material II;

[0034] ⑤ Mold casting: inject material II into the mold, shake it flat, and cure it for 24 hours at a temperature of 20±2°C and a relative humidity of >95%;

[0035] ⑥ demoulding;

[0036] ⑦ Curing at 20±2°C and relative humidity >95% for 28 days for experimental testing.

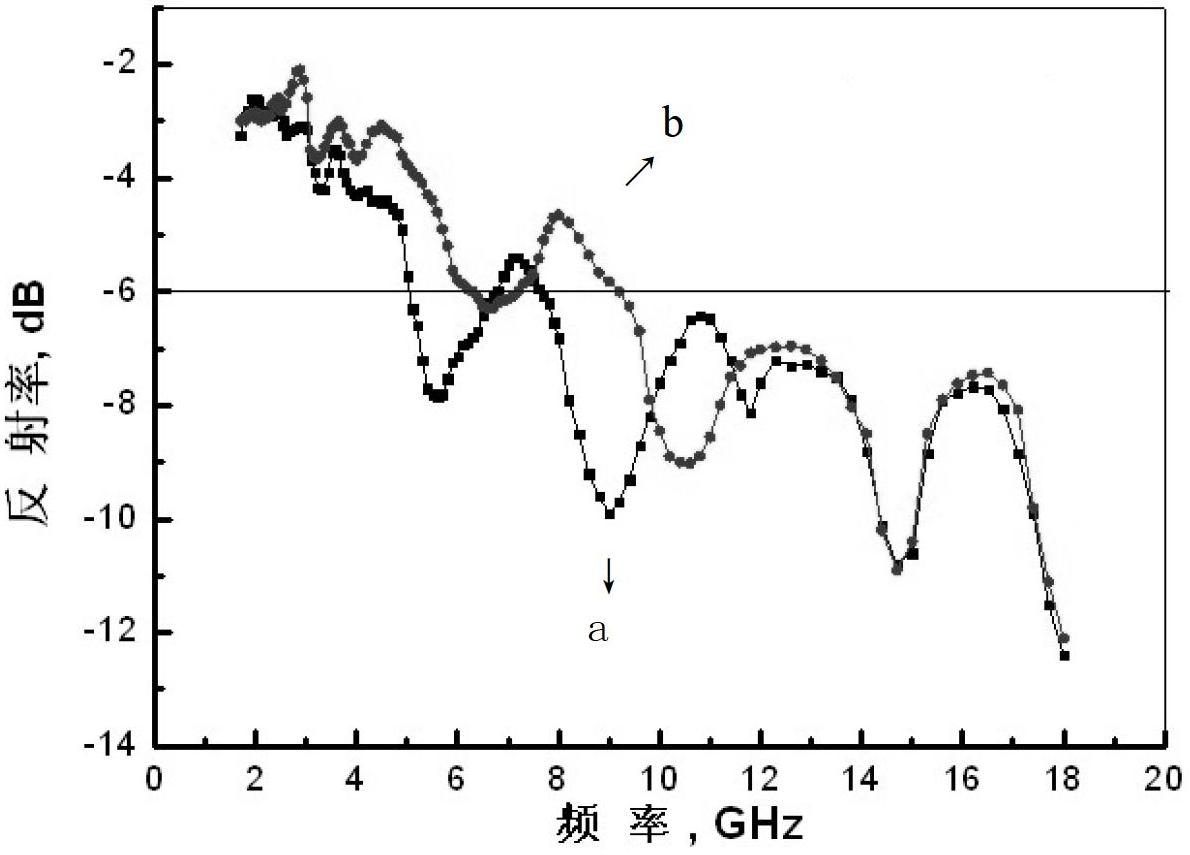

[0037] The foam concrete specimen made; the absolute dry bulk density is 480kg / m 3 , The size of the microwave-absorbing performance test specimen is 200mm×200mm×25mm, and the size of the thermal insulation performance test specimen is 300mm×300mm×20mm. ...

Embodiment 2

[0039] 1. Mix 36g of micron carbonyl iron powder and 36g of nano-carbon black with 1368g of sulphoaluminate cement, and stir evenly to obtain material I.

[0040] ②Mix 16g of animal and vegetable protein foaming agent with 112g of water, and make foam for 3 minutes to obtain foam;

[0041] ③ Mix material I, polycarboxylate high-efficiency water reducer and 608g water, and stir evenly to obtain a slurry;

[0042] ④ Add the foam to the slurry to mix, and stir evenly to obtain material II;

[0043] ⑤ Mold casting: inject material II into the mold, shake it flat, and cure it for 24 hours at a temperature of 20±2°C and a relative humidity of >95%;

[0044] ⑥ demoulding;

[0045] ⑦ Curing at 20±2°C and relative humidity >95% for 28 days for experimental testing.

[0046] The foam concrete specimen made; the absolute dry bulk density is 500kg / m 3 , The size of the microwave-absorbing performance test specimen is 200mm×200mm×25mm, and the size of the thermal insulation performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com