Wafer bonding process for transferring multiple wafers at one time

A chip and solid crystal technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of low transfer efficiency, achieve the effect of improving transfer efficiency and reducing the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

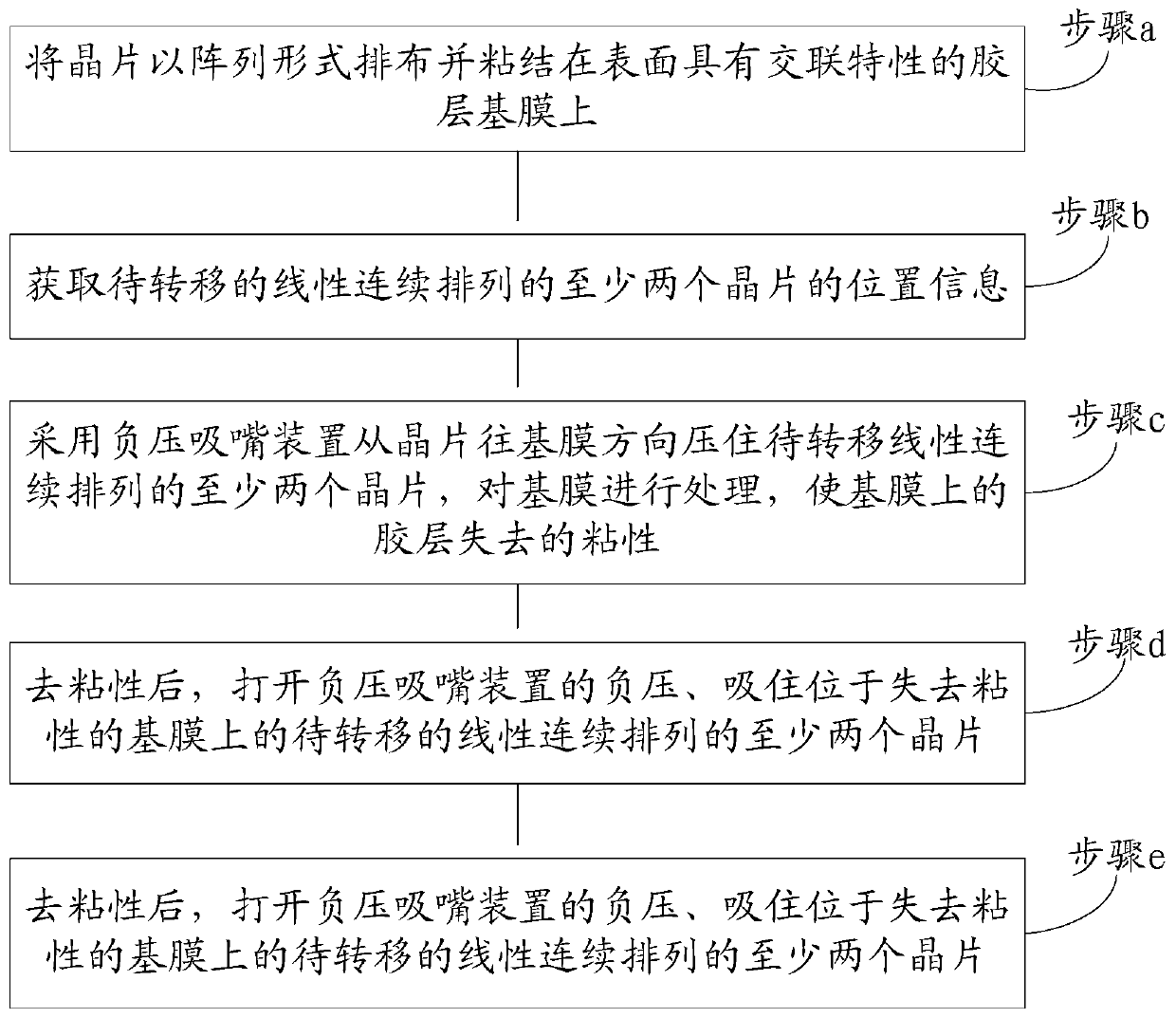

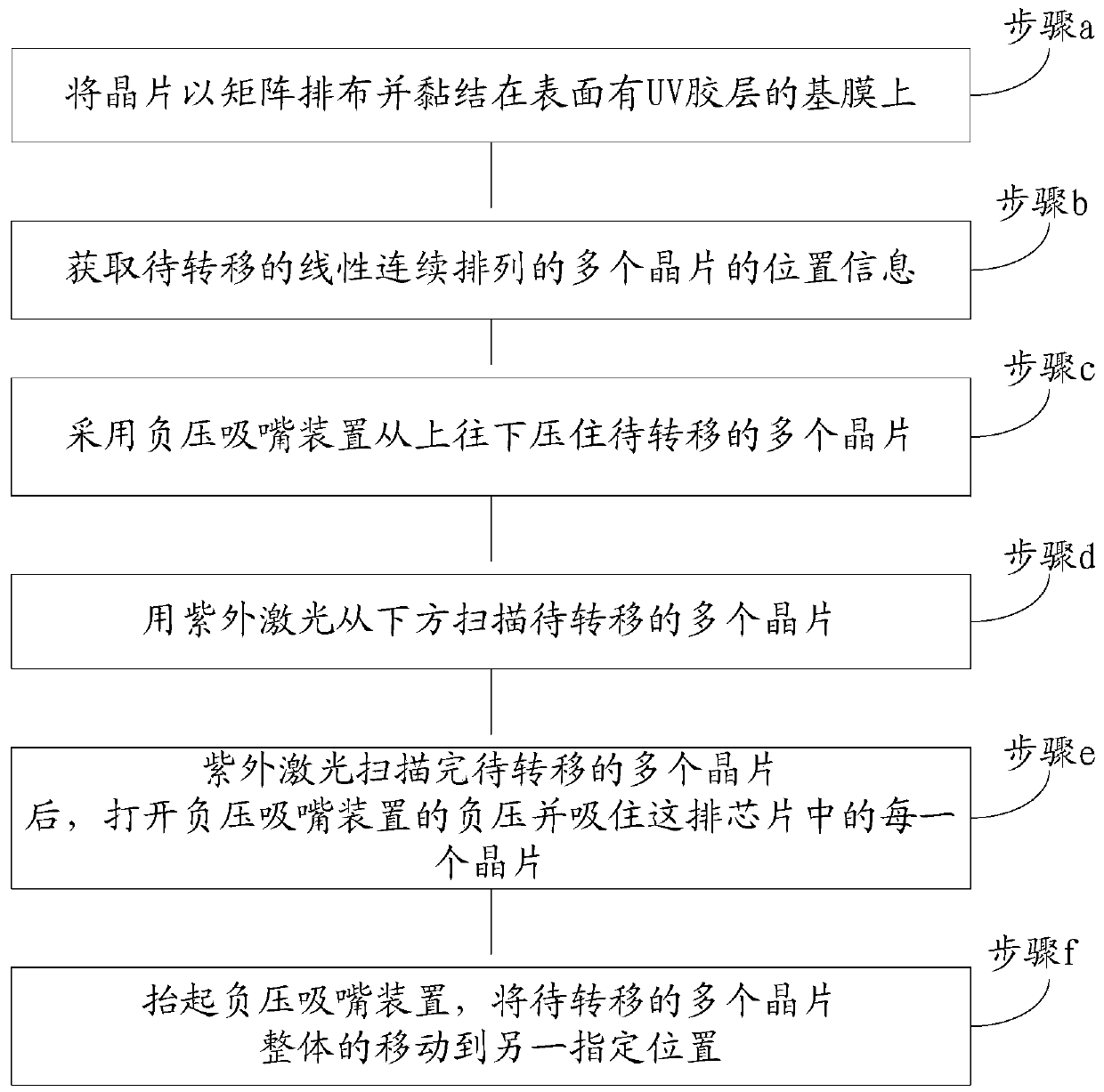

[0038] refer to figure 1 , the invention discloses a crystal-bonding process for transferring a plurality of wafers at a time. The wafers mainly refer to tiny chips, and these tiny chips are in an array (such as Figure 6 shown) are arranged on a base film (such as PET film or other types of films) with UV glue to form a dot matrix of chips. This base film with UV glue layer can be called a UV adhesive tape.

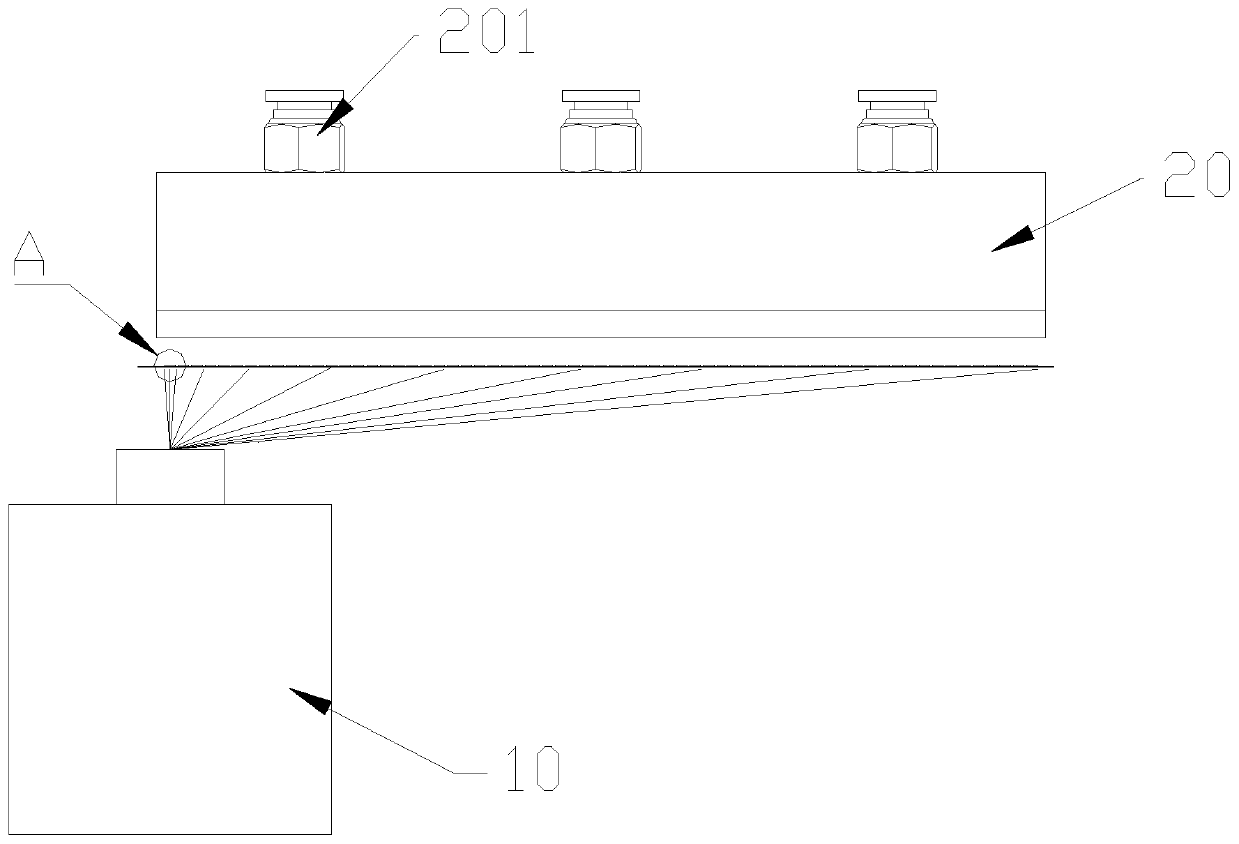

[0039] Chips are glued on PET film by UV glue. The PET film is located on the light-transmitting plate, which can transmit 220-400nm ultraviolet light; the ultraviolet light passing through the light-transmitting plate can make the UV glue lose its viscosity. The vibrating mirror device is arranged under the light-transmitting plate, and the vibrating mirror device here can also be replaced by an optical lens device. The optical lens can change the size and shape of the original UV spot, such as adjusting the final output UV spot to a rectangular UV spot.

[0040] A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com