Rope driving device for improving control accuracy

A rope drive and control precision technology, applied in the field of robot drive control, can solve the problems of easy wear and low control precision, and achieve the effects of improving control precision, easy maintenance and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

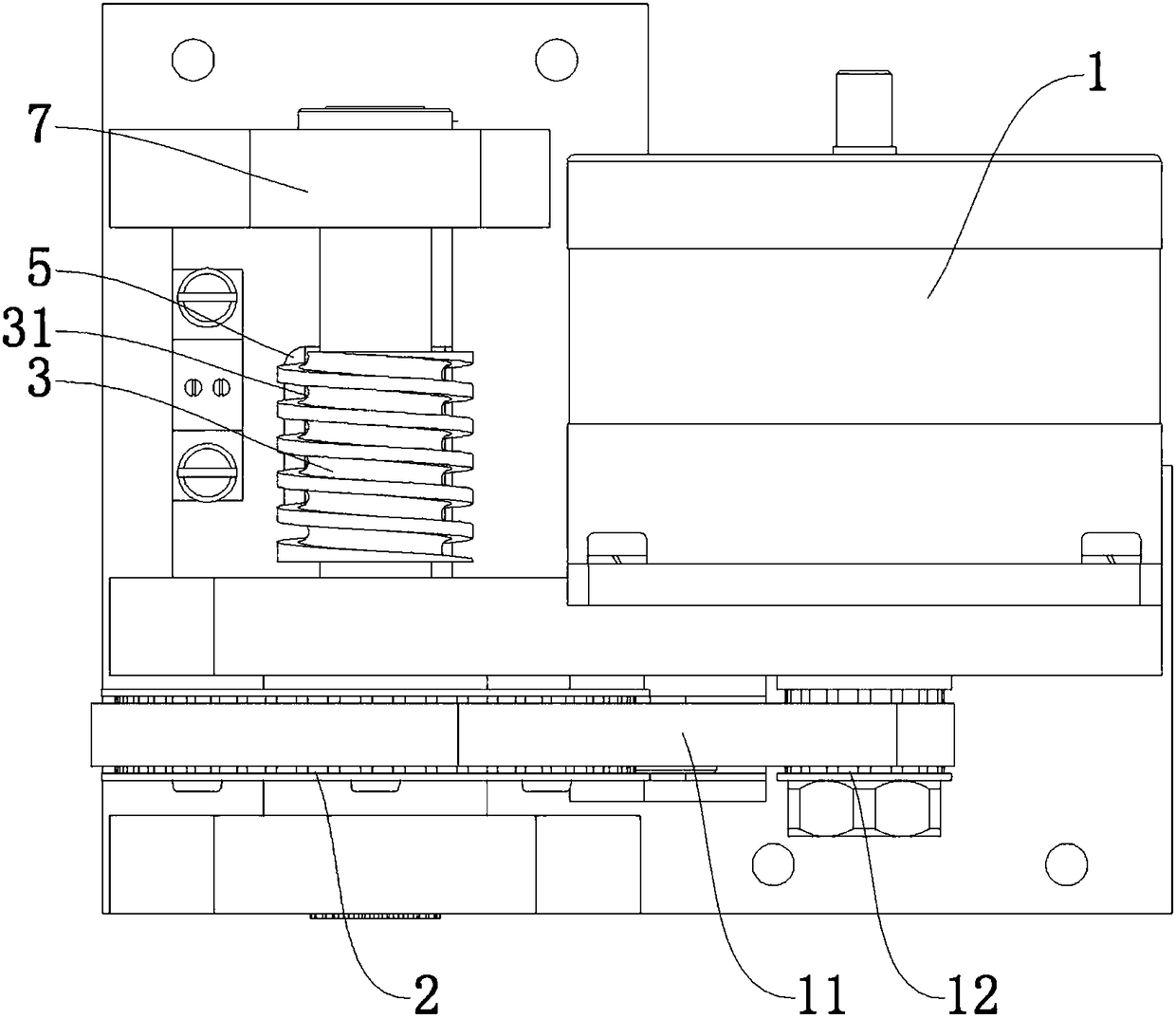

[0025] Such as Figure 1 to Figure 3 As shown, a rope driving device with improved control accuracy of the present invention includes a drive wheel 2 driven by a motor 1 , a reel 3 rotating with the drive wheel 2 , and a rope 4 wound on the reel 3 .

[0026] The motor 1, the transmission wheel and the reel 3 are respectively arranged on the mounting base, and the reel 3 can move axially relative to the transmission wheel 2 during the rotation. On the surface of the reel 3 is formed a helical groove 31 for locking the rope 4 . The axial movement rate of the reel 3 is the same as the axial movement rate of the rope 4 in the slot 31 .

[0027] The installation seat is provided with a guide member 5 for guiding the axial movement of the reel 3 . A helical guide groove 6 with the same helicity as the locking groove 31 is provided between the reel 3 and the guide member 5 , and a guide tooth 61 matched with the helical guide groove 6 is provided.

[0028] The transmission wheel 2...

Embodiment 2

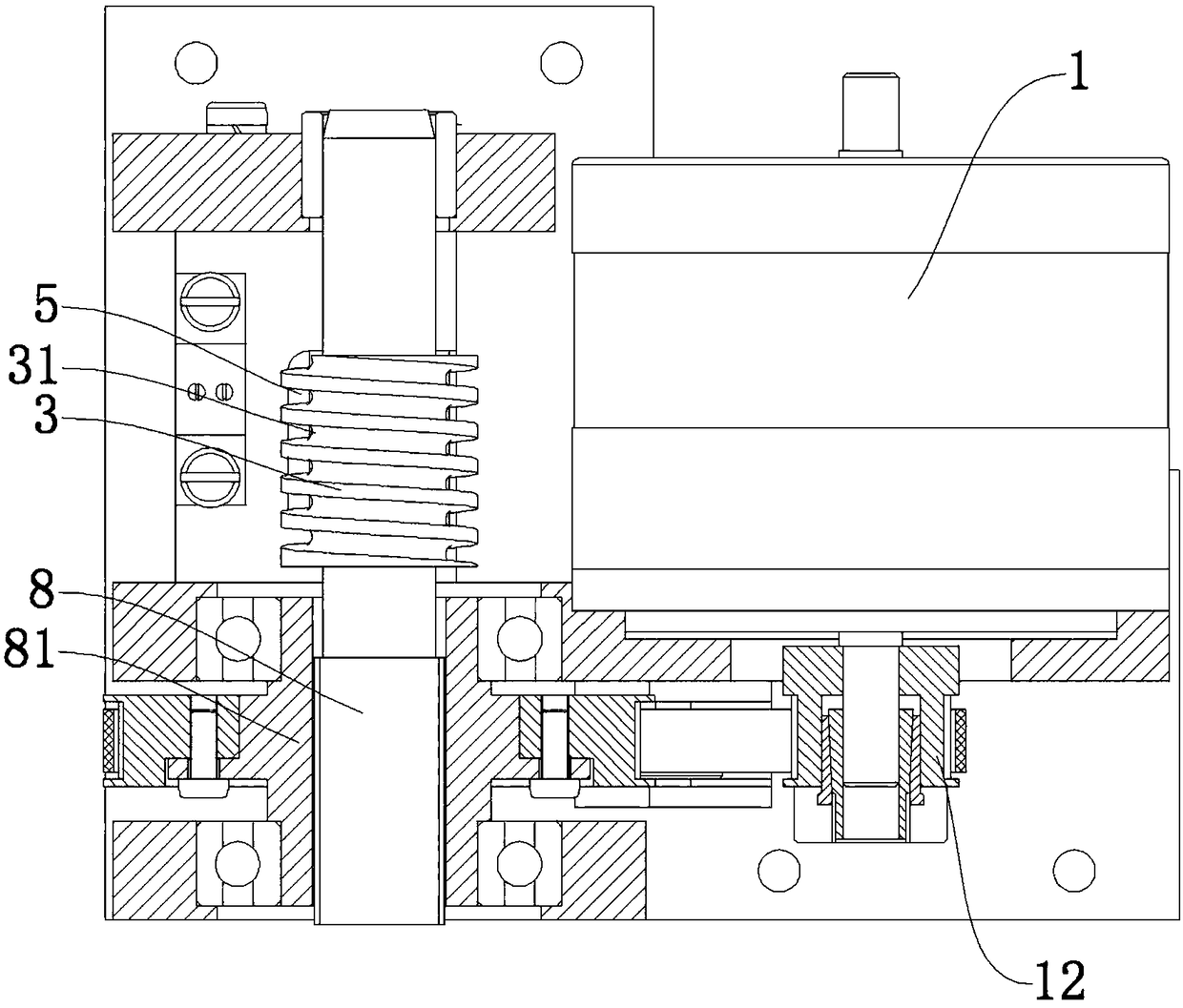

[0036] Such as Figure 4 and Figure 5 As shown, this embodiment is improved on the basis of embodiment 1. The difference from embodiment 1 is that in this embodiment, the spline shaft 8 is fixedly connected to the transmission wheel 2, and the spline shaft 8 adopts a ball spline. The spline shaft 8 is provided with a spline sleeve 81 capable of axial movement, and the reel 3 is mounted on the spline sleeve 81 .

[0037] The guide piece 5 of this embodiment is fixed on the side wall of the mounting base 7 and is located on one side of the traction hole 71. The guide teeth 61 on the guide piece 5 cooperate with the helical guide groove 6 on the upper part of the helical groove.

Embodiment 3

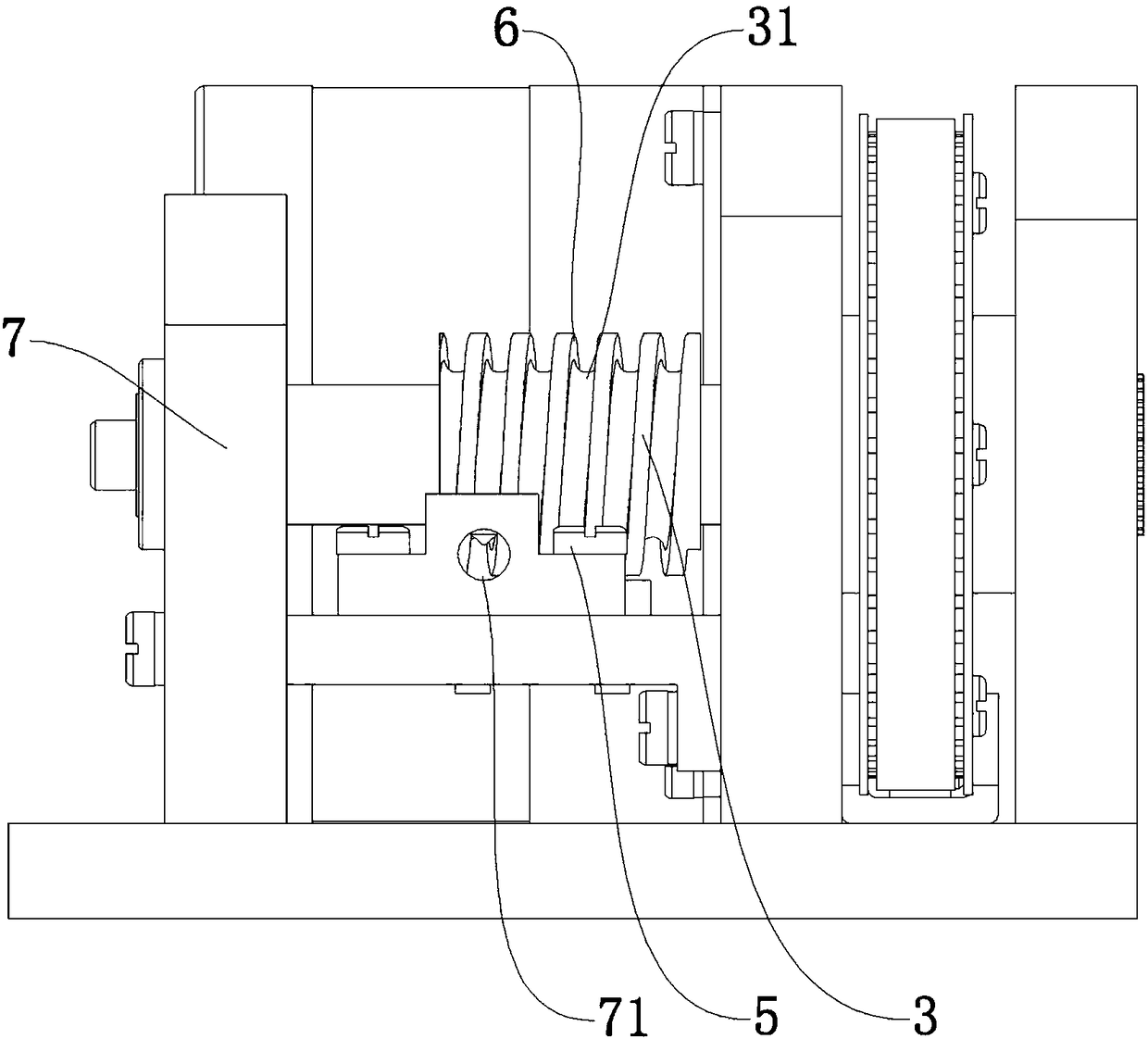

[0039] Such as Figure 6 to Figure 8 As shown, the rope driving device of this embodiment also includes a transmission wheel 2 driven by a motor 1 , a reel 3 rotating with the transmission wheel 2 , and a rope 4 wound on the reel 3 .

[0040] The motor 1, the transmission wheel and the reel 3 are respectively arranged on the mounting base, and the reel 3 can move axially relative to the transmission wheel 2 during the rotation. On the surface of the reel 3 is formed a helical groove 31 for locking the rope 4 . The axial movement rate of the reel 3 is the same as the axial movement rate of the rope 4 in the slot 31 .

[0041]The installation seat is provided with a guide member 5 for guiding the axial movement of the reel 3 . A helical guide groove 6 with the same helicity as the locking groove 31 is provided between the reel 3 and the guide member 5 , and a guide tooth 61 matched with the helical guide groove 6 is provided.

[0042] The transmission wheel 2 is rotatably arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com