Mattress edge matching machine and control method thereof

A technology of fringing machines and mattresses, which is applied to program-controlled sewing machines, bedding sewing machines, textiles and papermaking, etc. It can solve the problems of low automation and achieve operation time saving, fast response and accurate motion control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0062] It should be noted that the mattresses here can be various forms of mattresses such as spring mattresses, brown mattresses or latex mattresses.

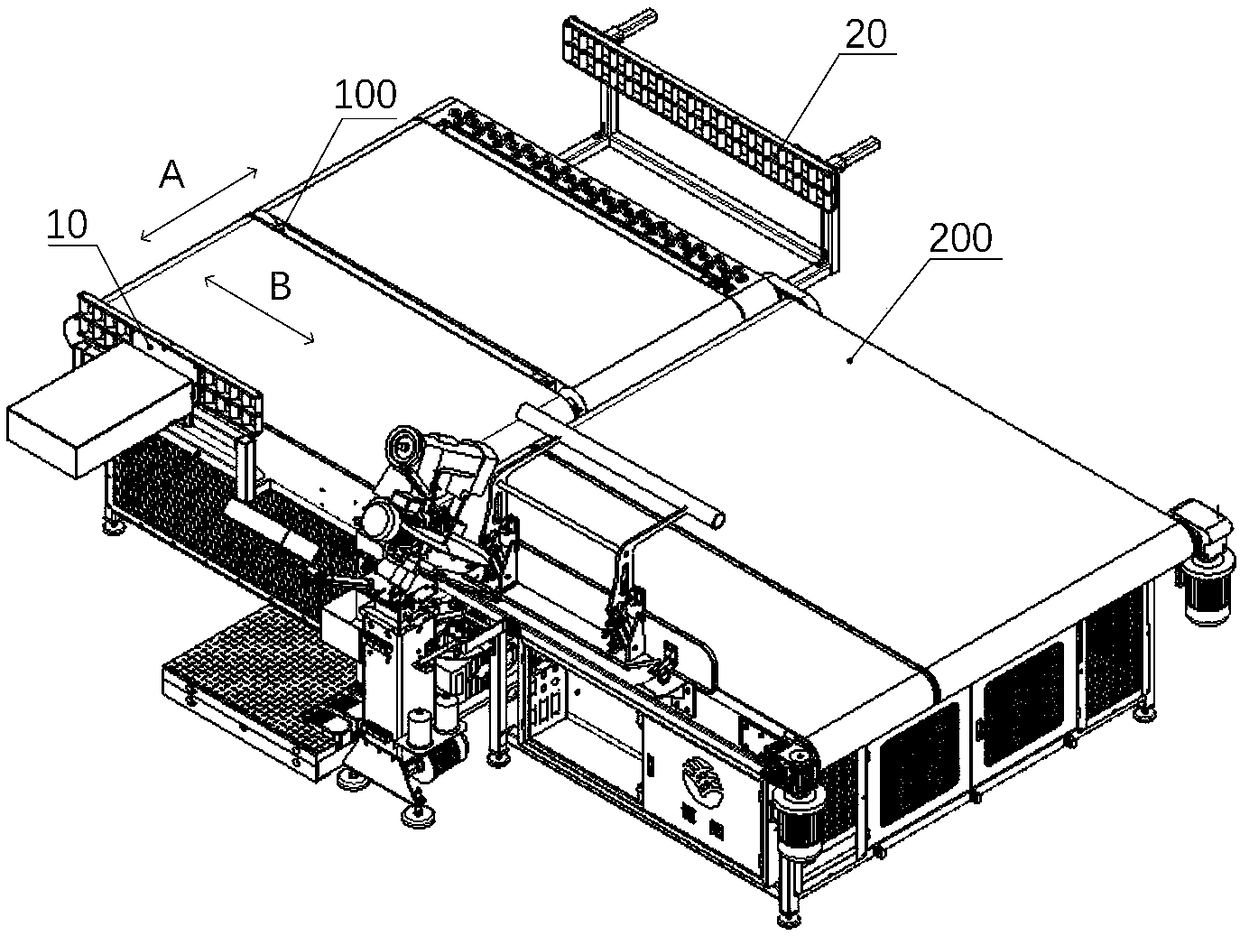

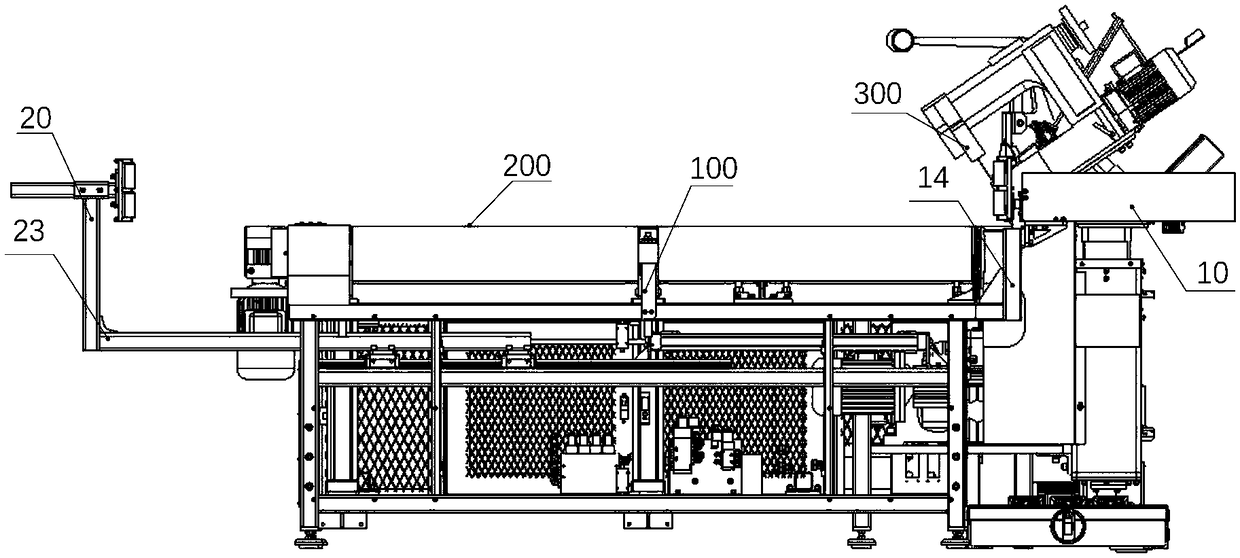

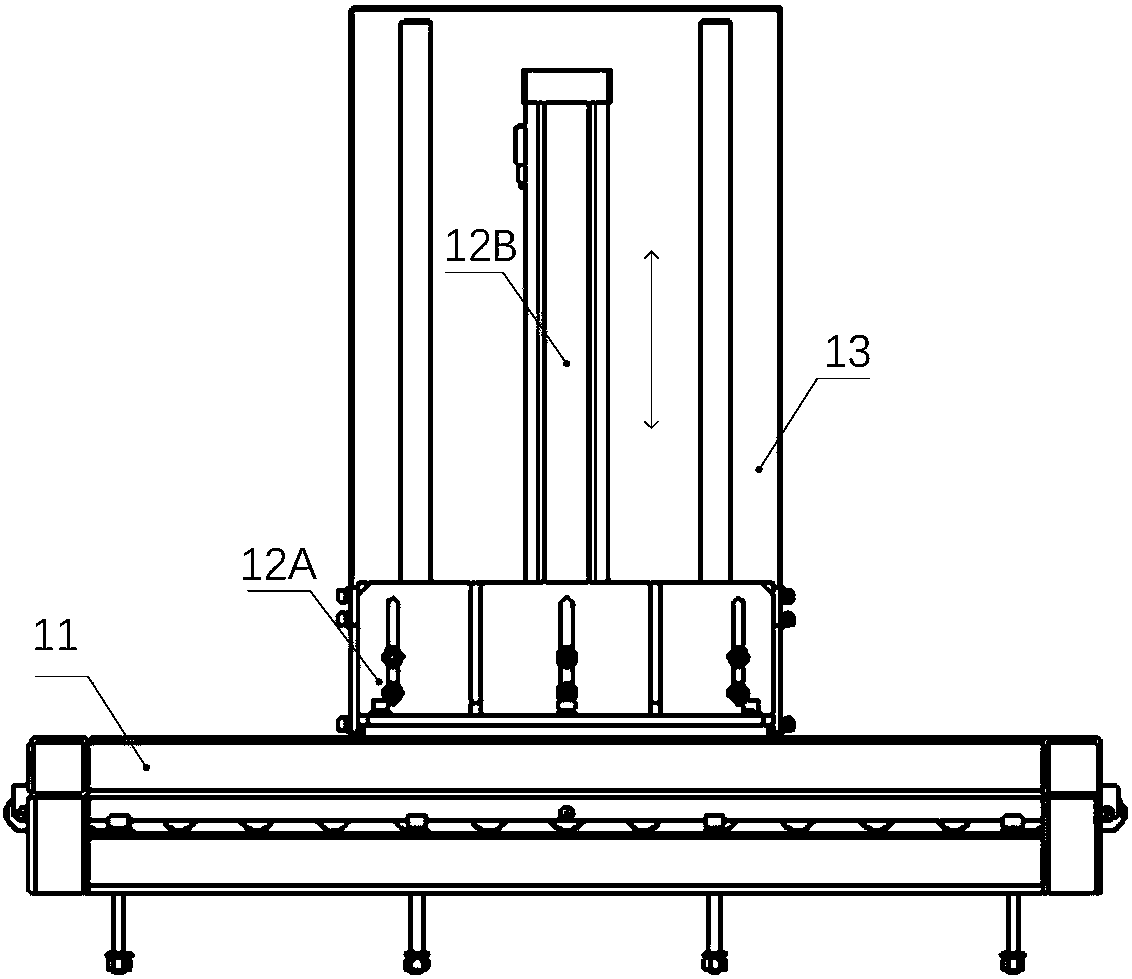

[0063] Currently, if figure 1 As shown, when the mattress edge machine with the function of turning over the bed is working, the mattress is transported by the conveyor belt along the mattress conveying plane to the position of the sewing machine head, and the upper end surface of the mattress and the fabric at the upper end of the side of the mattress are sewn together with the edge belt. , that is, the edge; after the peripheral edge of one end surface is completed, the mattress is turned over by the bed turning mechanism, so that the original lower end surface is turned into the upper end surface; and the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com