Rotation type welding device for silicon steel sheet

A welding device and rotary technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult manual control of welding trajectory, low quality of welding products, lack of automation equipment, etc., to improve the accuracy of welding torch motion control , easy installation and maintenance, and the effect of improving work efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

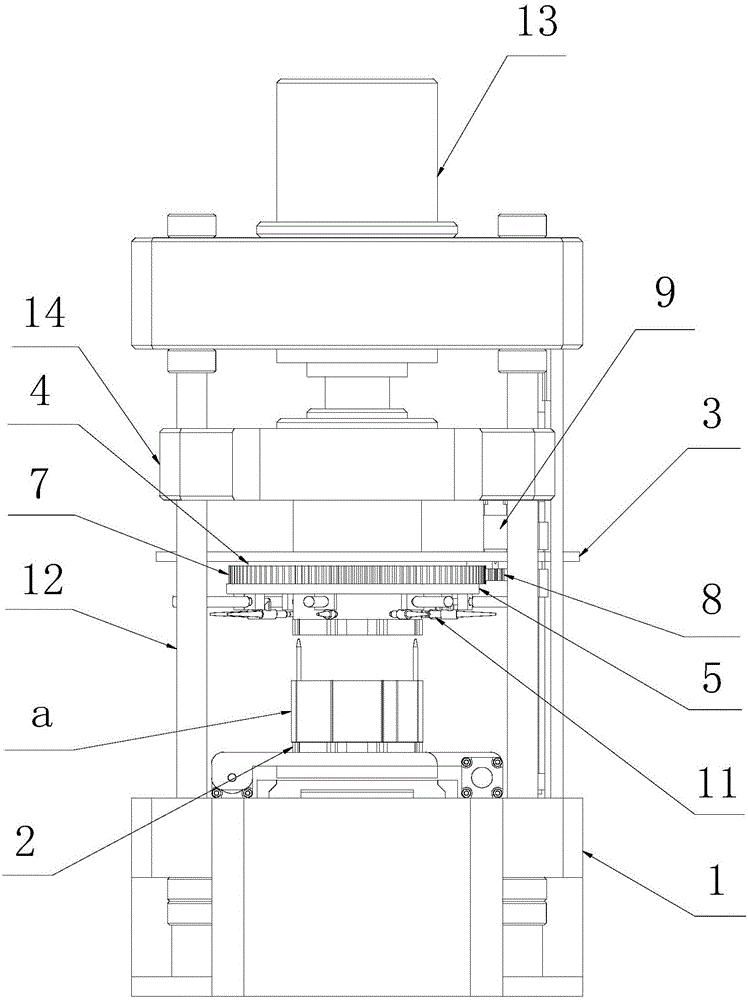

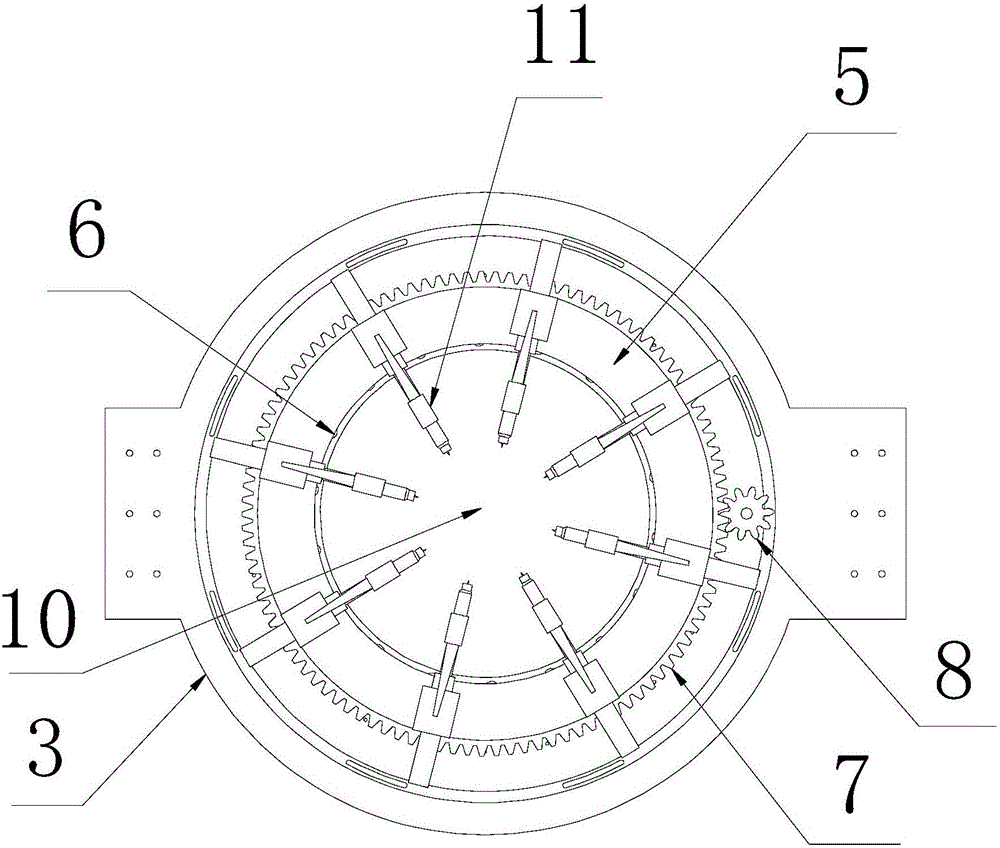

[0024] Example: specific combination figure 1 with figure 2 As shown, the specific implementation of the silicon steel sheet rotary welding device of the present invention is described as follows: it has a welding workbench 1 provided with a silicon steel sheet positioning tooling 2, and the welding workbench 1 is provided with a lifting mechanism and is controlled by the lifting mechanism. The mechanism drives the lifting rotary welding torch mechanism. The core design of the present invention is the rotary welding torch mechanism, which is composed as follows: it has a lifting plate 3, an annular mandrel 4 longitudinally fixed on the bottom of the lifting plate 3, and is sleeved on the annular mandrel 4 through a bearing 6 The welding torch positioning ring 5 on the top; the outer side of the welding torch positioning ring 5 is integrally provided with an outer gear ring 7, and the bottom of the lifting plate 3 is also pivotally provided with a horizontal rotation drive ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com