Pressure-flow whole-process-adaptive TBM (tunnel boring machine) propelling hydraulic system

A hydraulic system and whole-process technology, applied in the field of TBM propulsion hydraulic system, can solve the problems of increasing the flexibility of automatic deviation correction of the propulsion system and low efficiency of hydraulic cylinder cooperative control, achieving outstanding energy-saving effects, improving motion control accuracy, and reducing control difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

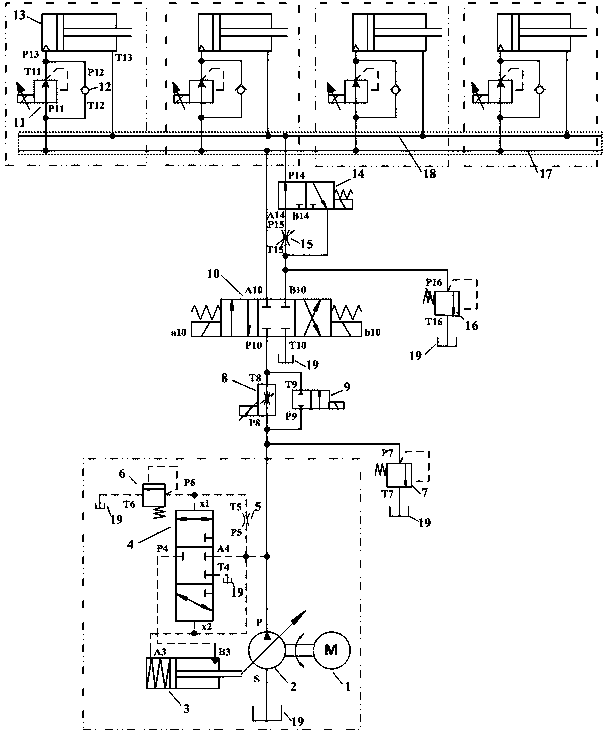

[0014] The TBM propulsion hydraulic system adapted to the whole process of pressure and flow includes an oil source and 4 hydraulic cylinders placed in parallel. Relief valve 6, safety valve 7, proportional speed regulating valve 8, two-position two-way reversing valve 9, three-position four-way proportional reversing valve 10, two-position three-way reversing valve 14, variable throttle port 15, proportional Relief valve 16, oil inlet pipe 17, oil return pipe 18 and oil tank 19; each hydraulic cylinder includes proportional pressure reducing valve 11, check valve 12, hydraulic cylinder 13, and the connection relationship between oil source and hydraulic cylinder is: motor 1 and variable The pump 2 is rigidly connected, the oil suction port S of the variable variable pump 2 communicates with the oil tank 19; the oil outlet P of the variable variable pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com