Synchronous coordinated sliding-mode control method for series-parallel automobile electrophoretic coating conveying mechanism based on comprehensive error

A conveying mechanism and electrophoretic coating technology, applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problems of not being well applicable, difficult to obtain motion control effect, difficult to ensure the accuracy of trajectory tracking motion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

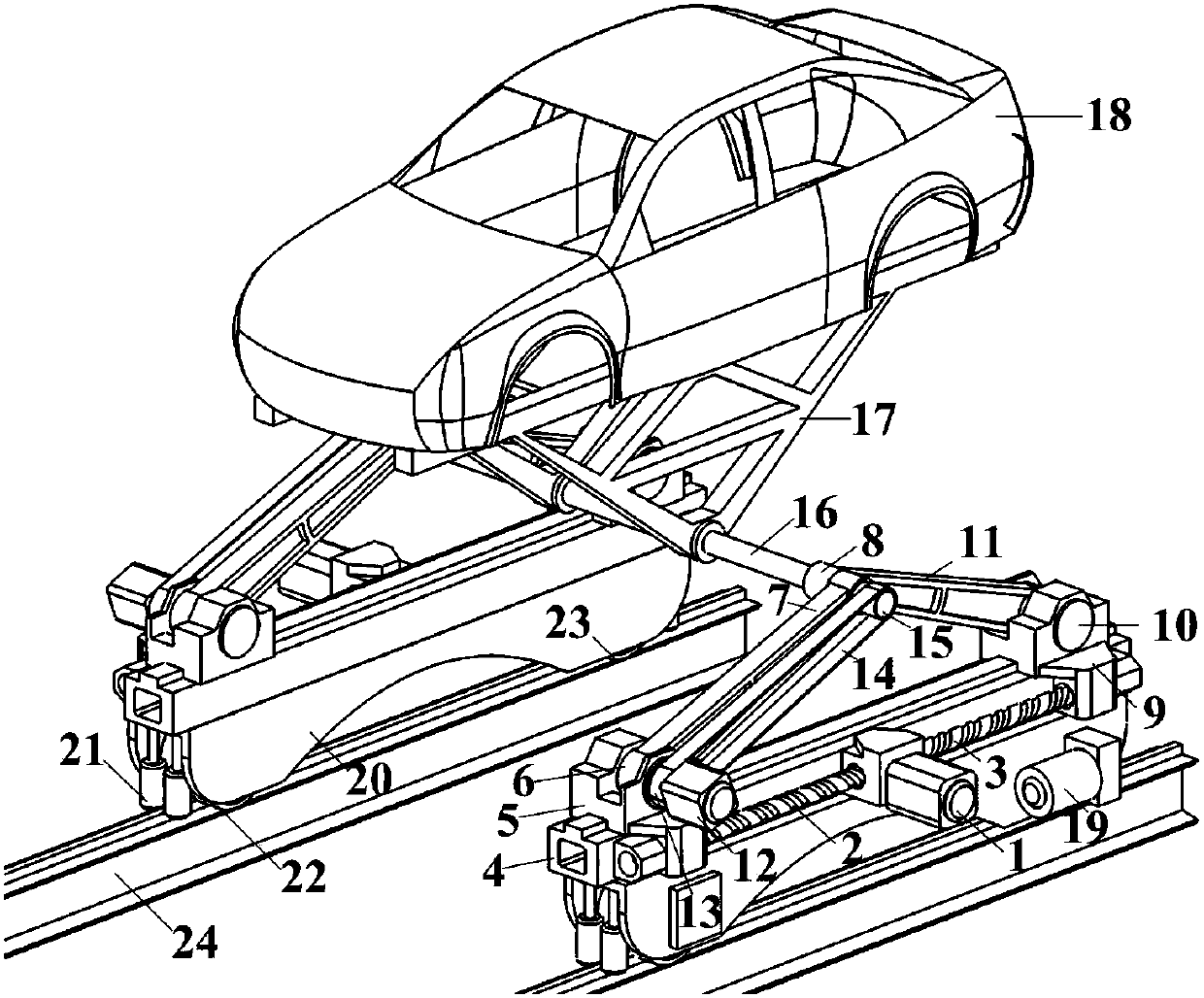

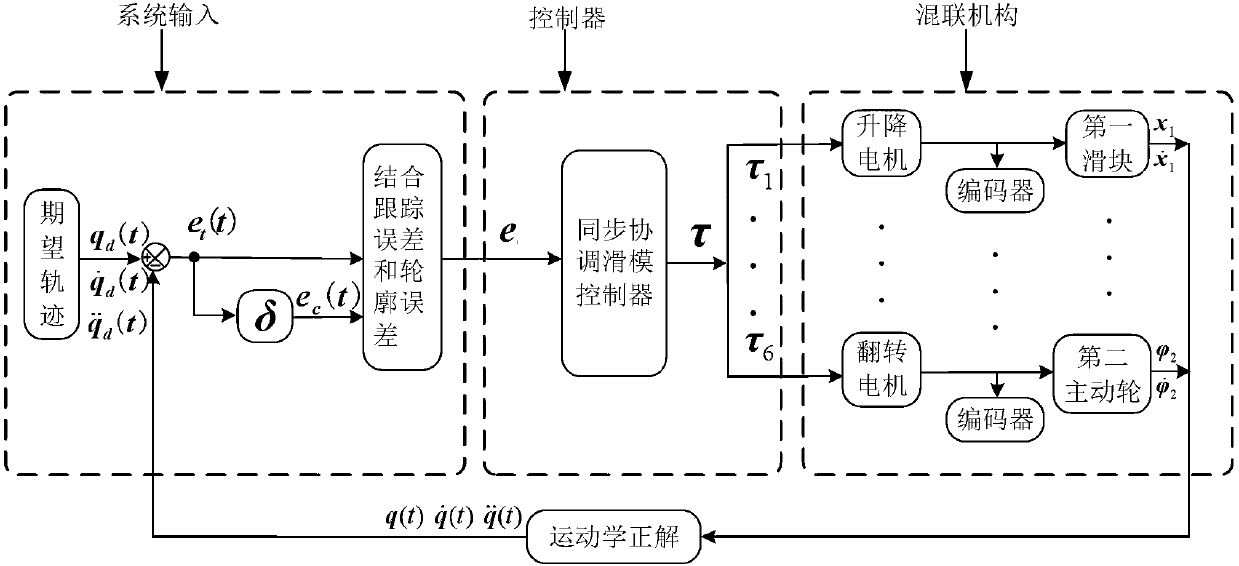

[0142] The present invention mainly focuses on using a synchronous coordination sliding mode control method based on comprehensive errors to improve the track tracking accuracy of the end of the mechanism so as to realize high-precision automobile electrophoretic coating delivery. The principle block diagram of the synchronous coordination sliding mode control based on the comprehensive error of the hybrid automobile electrophoretic coating conveying mechanism is as follows: figure 2 As shown, taking the developed prototype as an example, the specific implementation of the control method is as follows:

[0143] 1. Establish a dynamic model of the lifting and turning mechanism with unmodeled dynamics, friction and external random disturbances

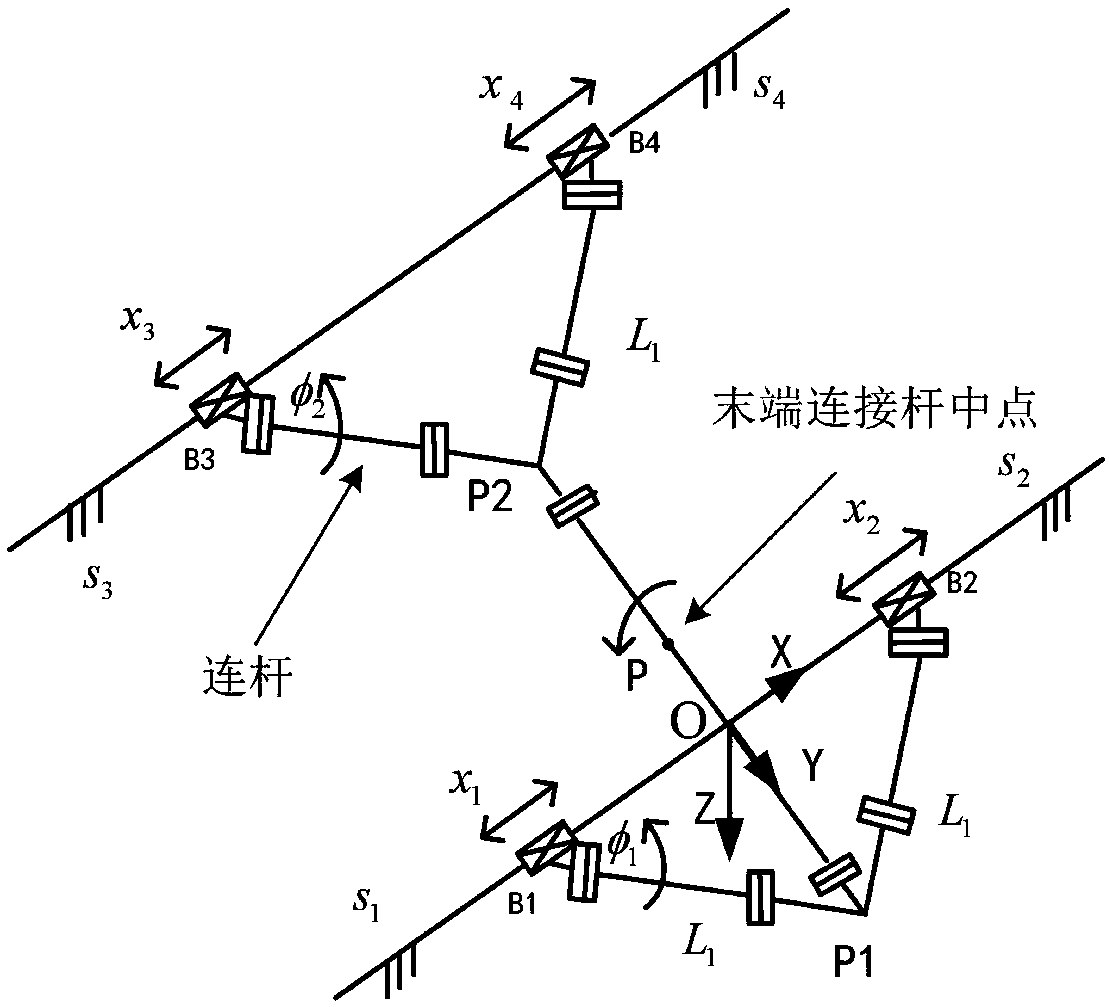

[0144] based on image 3 with S 1 and S 2 The midpoint O of is the origin to establish a basic coordinate system {B}={O-XYZ}, and its X axis is along the S 1 S 2 direction, the Y axis is parallel to P 2 P 1 , the Z axis is vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com