Full-automatic vertical winding machine provided with rotating disk

A fully automatic, wire take-up technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., which can solve the problems of automatic disc change, enameled wires are easy to break, and enameled wire winding process cannot be stable and orderly progress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in combination with specific embodiments.

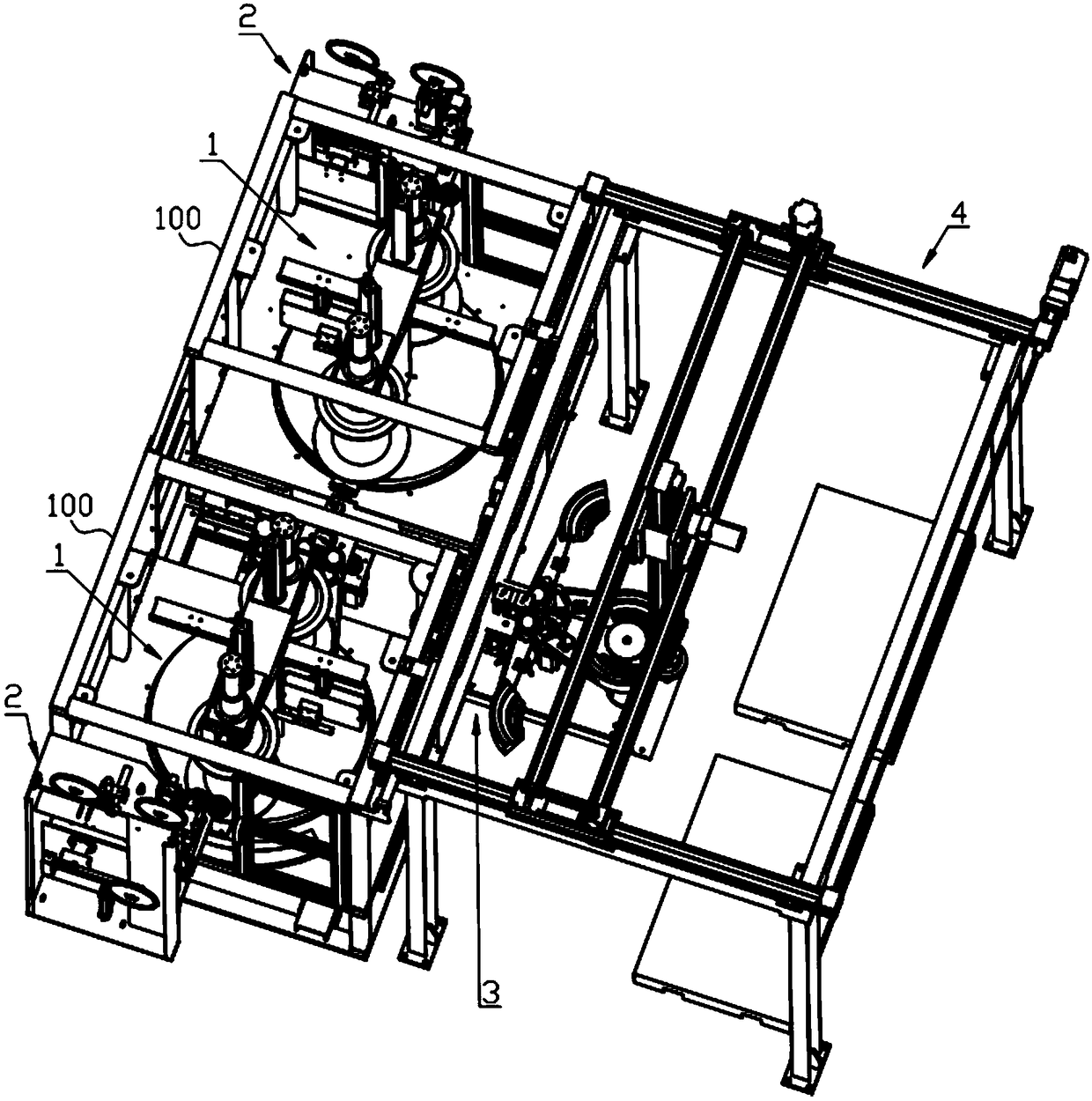

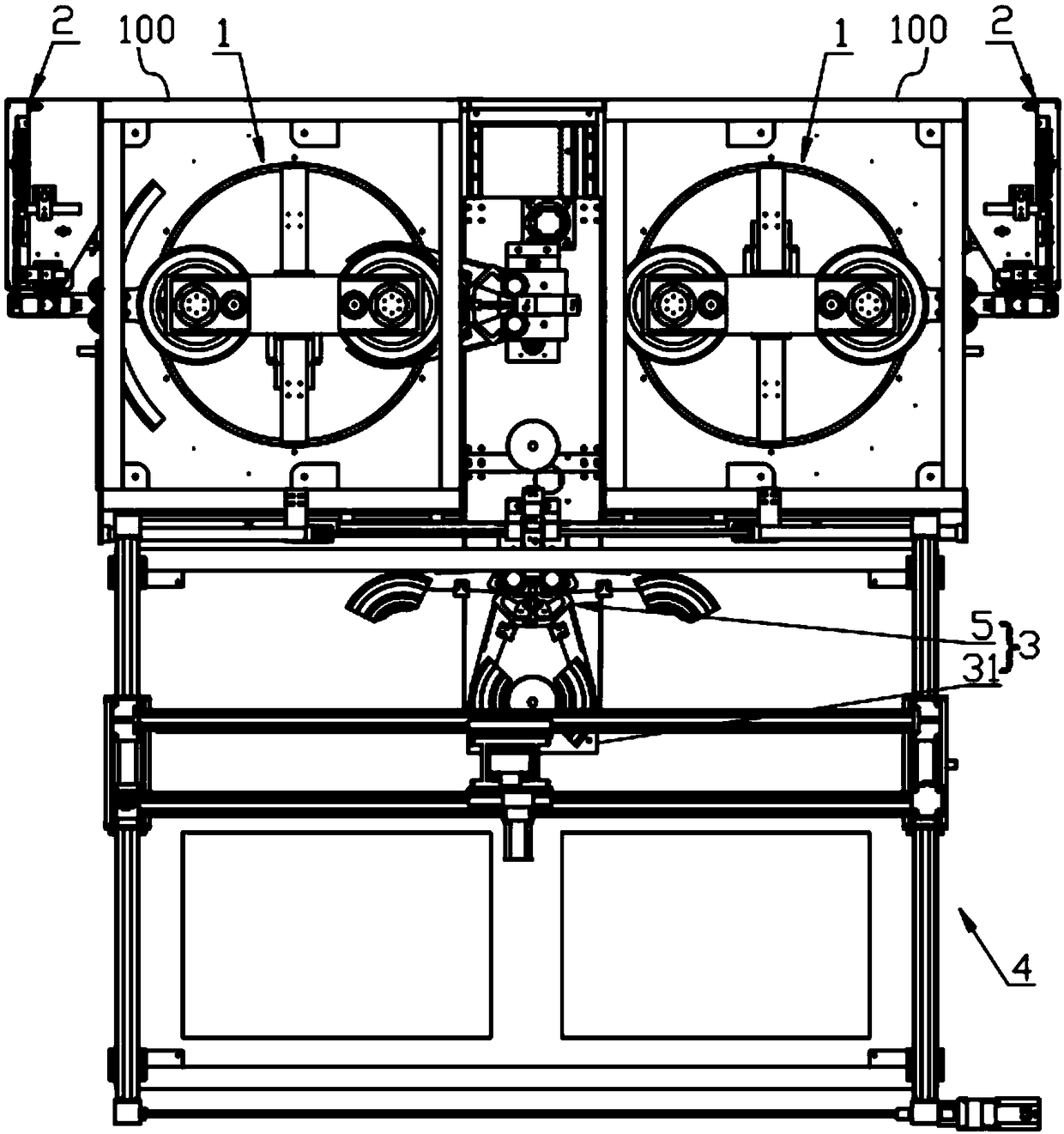

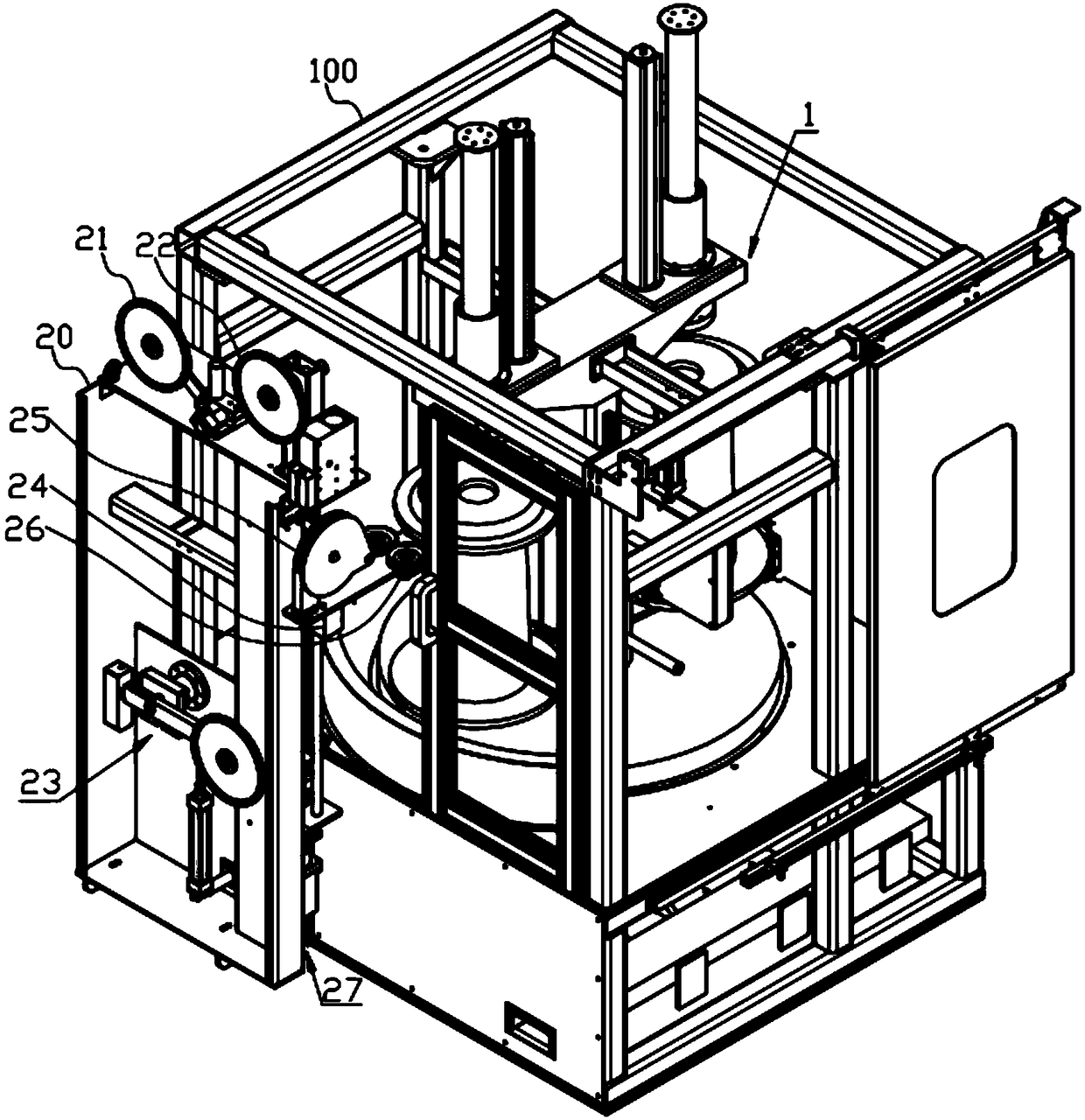

[0051] Such as figure 1 and 2 As shown, the fully automatic vertical turntable wire take-up machine according to an embodiment of the present invention includes a frame 100, the frame 100 is provided with a turntable type wire take-up device 1, and the opposite sides of the frame 100 are respectively provided with wire supports 2 . The wire reel loading and unloading device 3 , the wire reel loading and unloading device 3 extends below the three-coordinate transfer device 4 .

[0052] A set of three-coordinate transfer device 4 and reel loading and unloading device 3 can be equipped with a plurality of turntable type take-up devices 1, each turntable type take-up device 1 is placed in the frame 100, each turntable type take-up device 1 Equipped with independent wire support 2. A plurality of turntable type wire take-up devices 1 can be arranged in a line (this arrangemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com