Automatic coiling and uncoiling device for distribution circuit power cable

A power cable, automatic retractable technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of manual retraction of power cables, uneven cable arrangement, etc., to achieve balance of gravity and avoidance If the force is too large, the effect of ensuring the winding strength and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

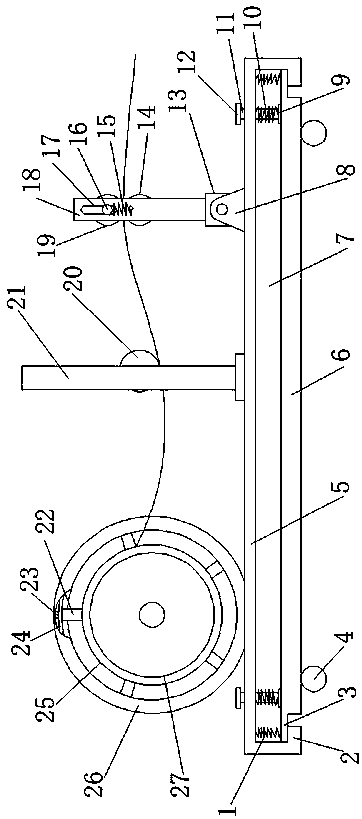

[0029] Such as figure 1 As shown, the power cable automatic retracting device for distribution lines includes a base 5, a cavity I7 is provided at the bottom of the base 5, a sliding plate 6 is provided in the cavity I7, and limit protrusions 3 are provided at both ends of the sliding plate 6, and the cavity The lower end of I7 is provided with a limit block 2 matching with the limit protrusion 3, universal rollers 4 are installed at the four corners of the lower end of the sliding plate 6, and a tension spring 1 is arranged between the sliding plate 6 and the top wall of the cavity I7. The sliding plate 6 is contracted upward by the tension spring 1, and the base 5 can be placed on the ground stably. The base 5 is provided with an ejection device for pushing the sliding plate 6 downward, and the sliding plate 6 is pushed downward by the ejection device. out, so that the universal roller 4 touches the ground, which facilitates the movement of the entire frame and is easy to use....

Embodiment 2

[0035] It differs from Embodiment 1 in that: as figure 1 As shown, the ejector device includes an adjustment rod 11 slidingly connected to the four corners of the base 5, the adjustment rod 11 extends into the cavity I7, the bottom of the adjustment rod 11 is fixedly connected with a support pad 9, and the support pad 9 leans against the sliding plate 6 On the upper end surface, the adjustment rod 11 is covered with a compression spring 10, and the two ends of the compression spring 10 are respectively abutted against the top wall of the cavity I7 and the upper end surface of the support plate 9, and the top of the adjustment rod 11 is connected with a handle 12. The rod 11 is fixed on the base 5 by a limit pin.

[0036] When the adjustment rod 11 is fixed on the base 5 through the limit pin, the sliding plate 6 is contracted upward by the tension spring 1, and the base 5 is placed on the ground stably; when the sliding plate 6 needs to be ejected downward, the limit pin is pu...

Embodiment 3

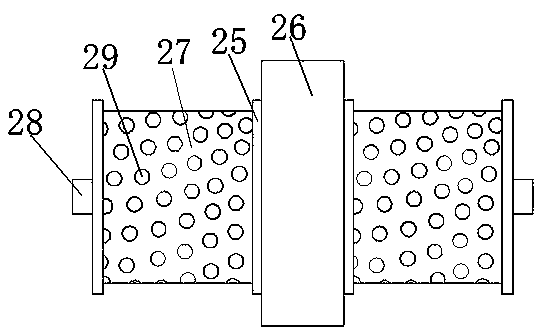

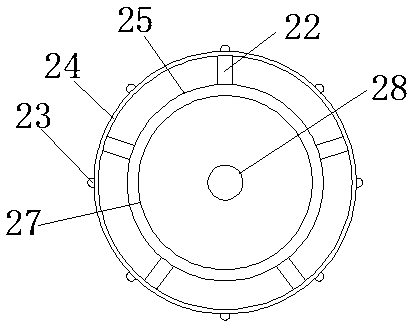

[0038] It differs from Embodiment 1 in that: as figure 2 As shown, the reel 27 is provided with a weight-reducing hole 29, which can reduce the weight of the reel, facilitate the movement and portability of the entire frame, and accelerate the retracting and unwinding of the cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com