Judgment method of start-up washing machine self-cleaning program

A self-cleaning, washing machine technology, applied in the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems of clothing pollution, non-detection of self-cleaning effect, waste of water and electricity resources, etc., and achieve the effect of accurate judgment results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The first embodiment of the present invention provides a method for initiating a self-cleaning program using a dirtiness sensor of a washing machine.

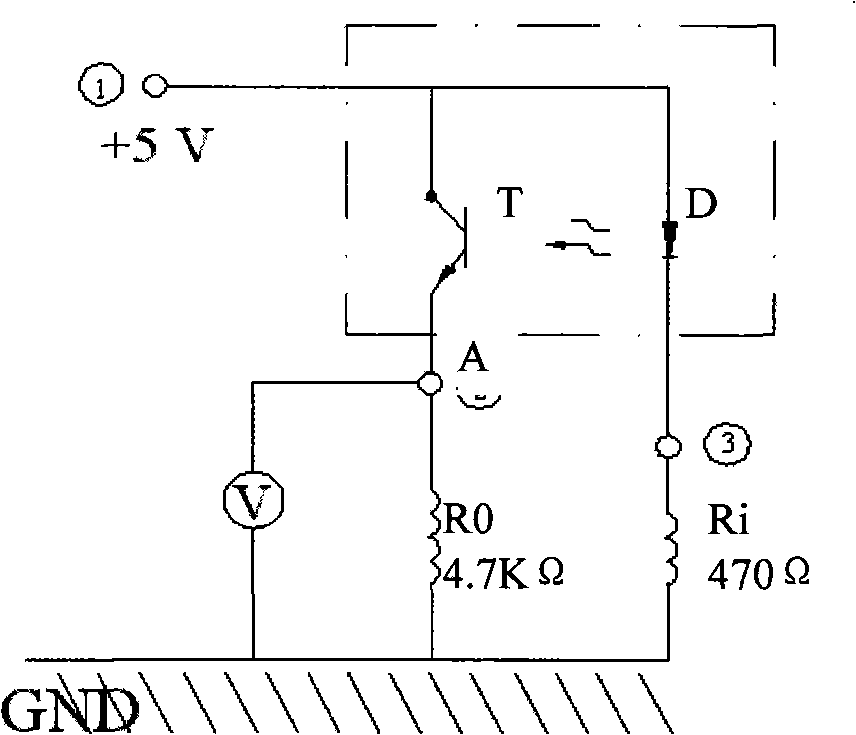

[0028] The method utilizes the turbidity sensor installed in the washing machine to obtain the conditions for starting the self-cleaning program. The turbidity sensor is applied to the washing machine to detect the degree of turbidity of the water discharged during the rinsing process. The washing machine can perform rinsing according to the actual degree of dirtiness of the clothes. The times of rinsing are less for cleaner clothes, and more times for dirty clothes.

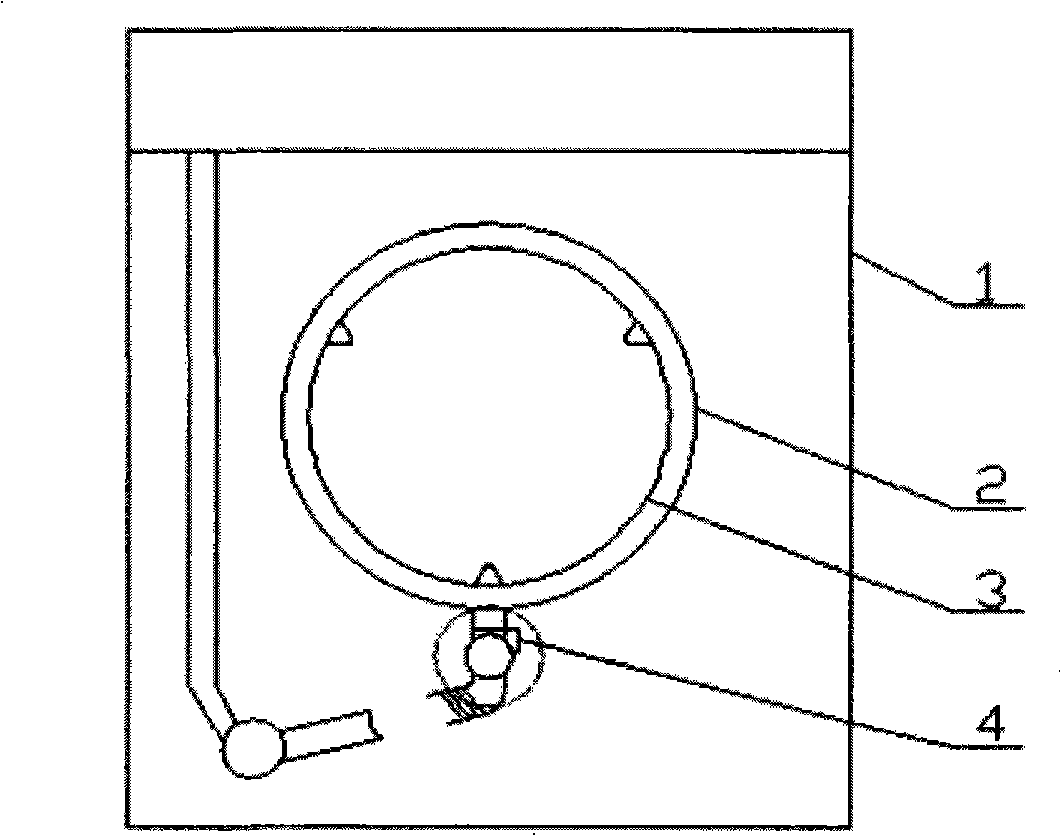

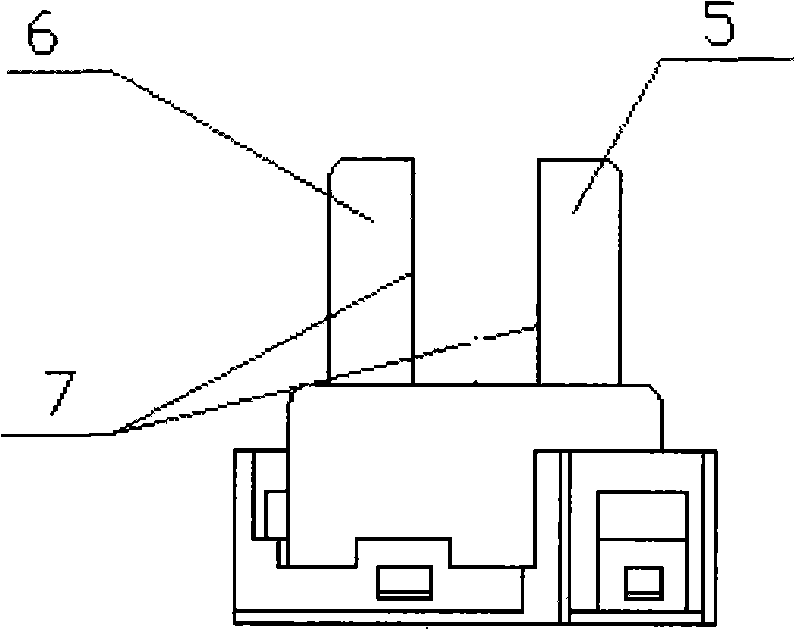

[0029] Please see figure 1 , which is a schematic diagram of the installation position of the turbidity sensor in the drum-type washing machine. figure 1 The shell 1, the outer tub 2, the inner tub 3, and the turbidity sensor 4 of the washing machine are shown in the figure. From figure 1 It can be seen from the figure that the turbidity sensor is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com