Method for detecting steel tube void of concrete filled steel tube (CFST) arch bridge by utilizing transient impact method

A technology of steel pipe concrete and impact method, which is applied in the generation of ultrasonic/sonic/infrasonic waves, and the use of sound waves/ultrasonic/infrasonic waves to analyze solids, etc., which can solve the problems of ultrasonic detection sensitivity and signal-to-noise ratio deterioration, difficult identification, component damage, etc. , to achieve the effect of simple operation and accurate and reliable judgment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

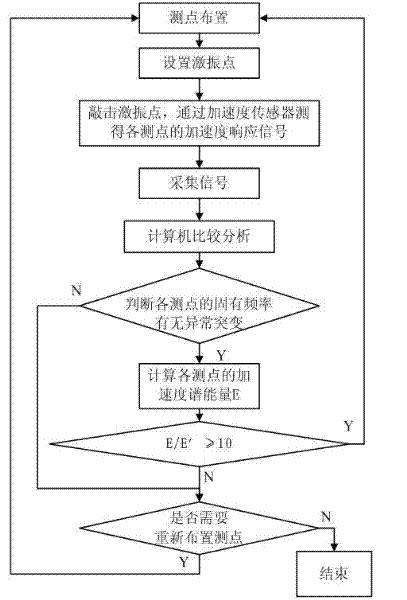

[0040] see figure 1 , the method for detecting the emptying of steel tubes of concrete-filled steel tube arch bridges by using the transient impact method, is characterized in that: comprising the following steps:

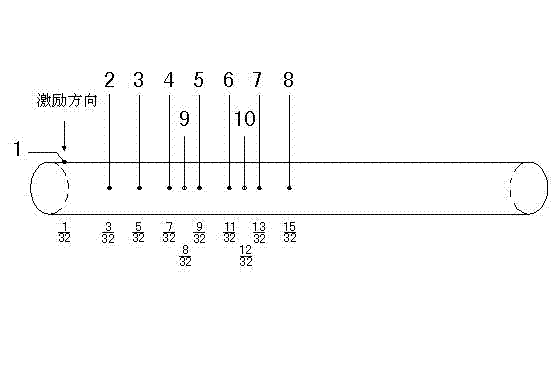

[0041] Step 1. Arrangement of measuring points: A plurality of measuring points are arranged in the axial direction on the top of the concrete-filled steel pipe to be tested, and an acceleration sensor 101 is placed on each measuring point;

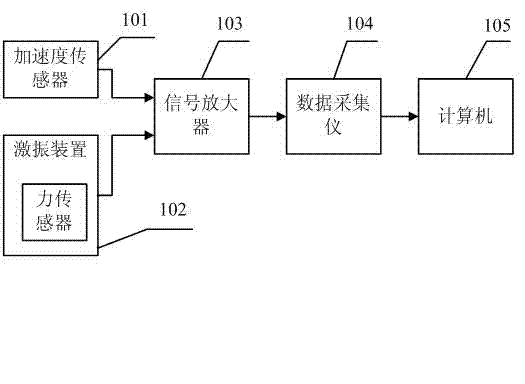

[0042] Second step. The excitation point is set on the outer wall near the head end or tail end of the steel tube concrete steel pipe, and the vibration excitation point is knocked horizontally by the vibration excitation device 102, and the acceleration response signal of each measuring point is recorded by the acceleration sensor 101; and, A force sensor is set in the excitation device 102, so that when the excitation point is knocked horizontally by the vibration excitation device 102, the impact force value is measured by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com