Ultrafiltration membrane alkaline cleaner

An ultrafiltration membrane and cleaning agent technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as adverse environmental effects, cumbersome steps, equipment corrosion, etc., to shorten cleaning time and simplify cleaning. Steps, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

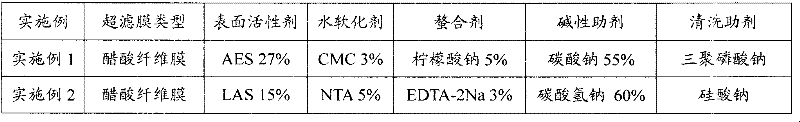

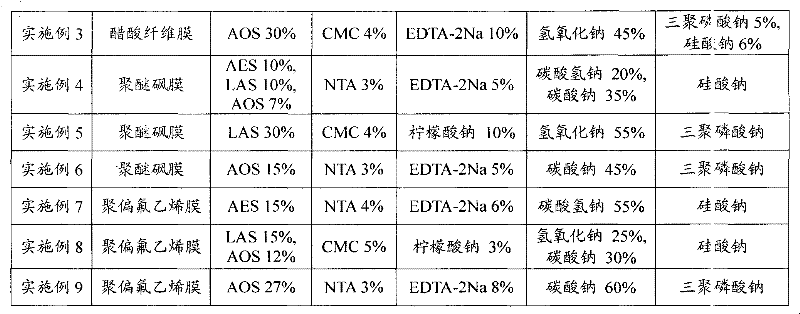

[0023] The types of ultrafiltration membranes and the components and mass percentages of alkaline cleaning agents in different embodiments are shown in Table 1. Wherein, the mass percentage of cleaning aid is 100% minus the mass percentage of other components. AES is sodium fatty alcohol polyoxyethylene ether sulfonate, LAS is sodium dodecylbenzene sulfonate, AOS is sodium α-olefin sulfonate, CMC is carboxymethyl cellulose, NTA is sodium nitrilotriacetate, EDTA -2Na is disodium EDTA.

[0024] Table 1

[0025]

[0026]

[0027] The preparation method of the ultrafiltration membrane alkaline cleaning agent is as follows: take the surfactant, alkaline additive, water softener, chelating agent, and cleaning additive according to the formula ratio, and add the above-mentioned components under stirring conditions. In the kettle, fully stir evenly to obtain the ultrafiltration membrane alkaline cleaning agent.

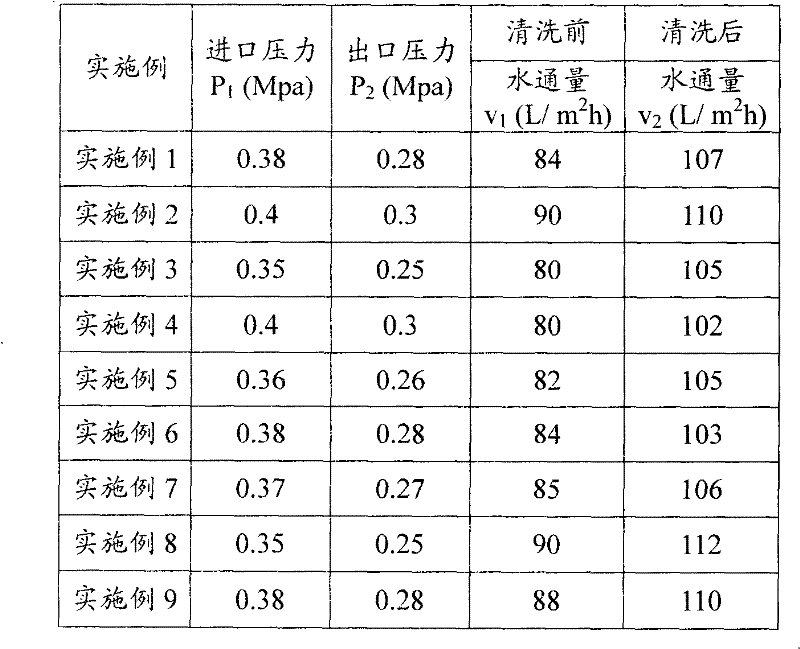

[0028] After the ultrafiltration treatment of the guronic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com