Working table for avoiding scattering of scraps in mechanical part machining process

A technology of mechanical parts and processing process, which is applied in the field of workbench to avoid the scattering of scraps during the processing of mechanical parts, and can solve the problems of inconvenient cleaning of scraps and scattering of scraps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

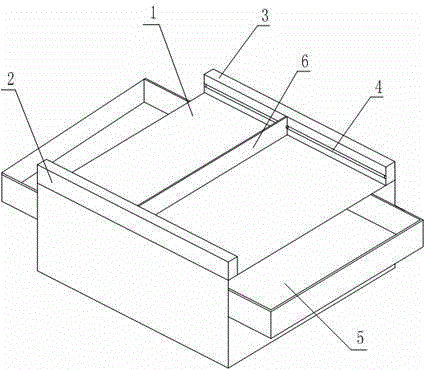

[0016] Such as figure 1 The shown workbench for avoiding the scattering of scraps during the machining of mechanical parts includes a square table body 1. The front and rear edges of the upper surface of the table body 1 are respectively provided with a vertical to the upper surface of the table body 1. No. 2 baffle 2, No. 2 baffle 3, the inner surface of the No. 1 baffle 2, the No. 2 baffle 3 is provided with a sliding groove 4 along the axial direction, and the sliding groove 4 is provided with a roller, The two rollers are connected by a scraper 6. The bottom 6 of the scraper is adjacent to the upper surface of the table body 1, and drawers 5 are provided on both the left and right sides of the table body 1. . In this embodiment, the two rollers are integrated with the scraper 6 fixed between the two rollers, and they can run along the chute 4 on the inner surface of the first baffle 2 and the second baffle 3. Since the bottom edge of the scraper 6 is adjacent to the upper...

Embodiment 2

[0018] Such as figure 1 On the basis of embodiment 1, the height of the scraper 6 and the first baffle 2 and the second baffle 3 are the same; Both ends of the sliding groove 4 are provided with stoppers. When processing mechanical parts in this embodiment, push the scraper 6 along the sliding groove 4 to the edge of the platform 1, and make it the same height as the No. 1 baffle 2, No. 2 The height of the baffle plate 3 is consistent, so as to prevent the scraper 6 from being too high to interfere with the actions of the operator and affect the processing of parts. After finishing a process, the scraper 6 is pushed to move it from one side of the table body 1 to the other side, so as to complete the cleaning of the surface of the table body 1. At the same time, the stoppers arranged at both ends of the sliding groove 4 can restrict the movement of the roller in the sliding groove 4, and prevent the user from sliding out of the sliding groove 4 and falling to the ground due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com