Pressing-type rotary cleaning machine for cylindrical roller bearings

A cylindrical roller bearing, pressure-dynamic technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as difficult cleaning, dirty cleaning, unsatisfactory bearing effect, etc. , to achieve the effect of improving cleaning effect and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

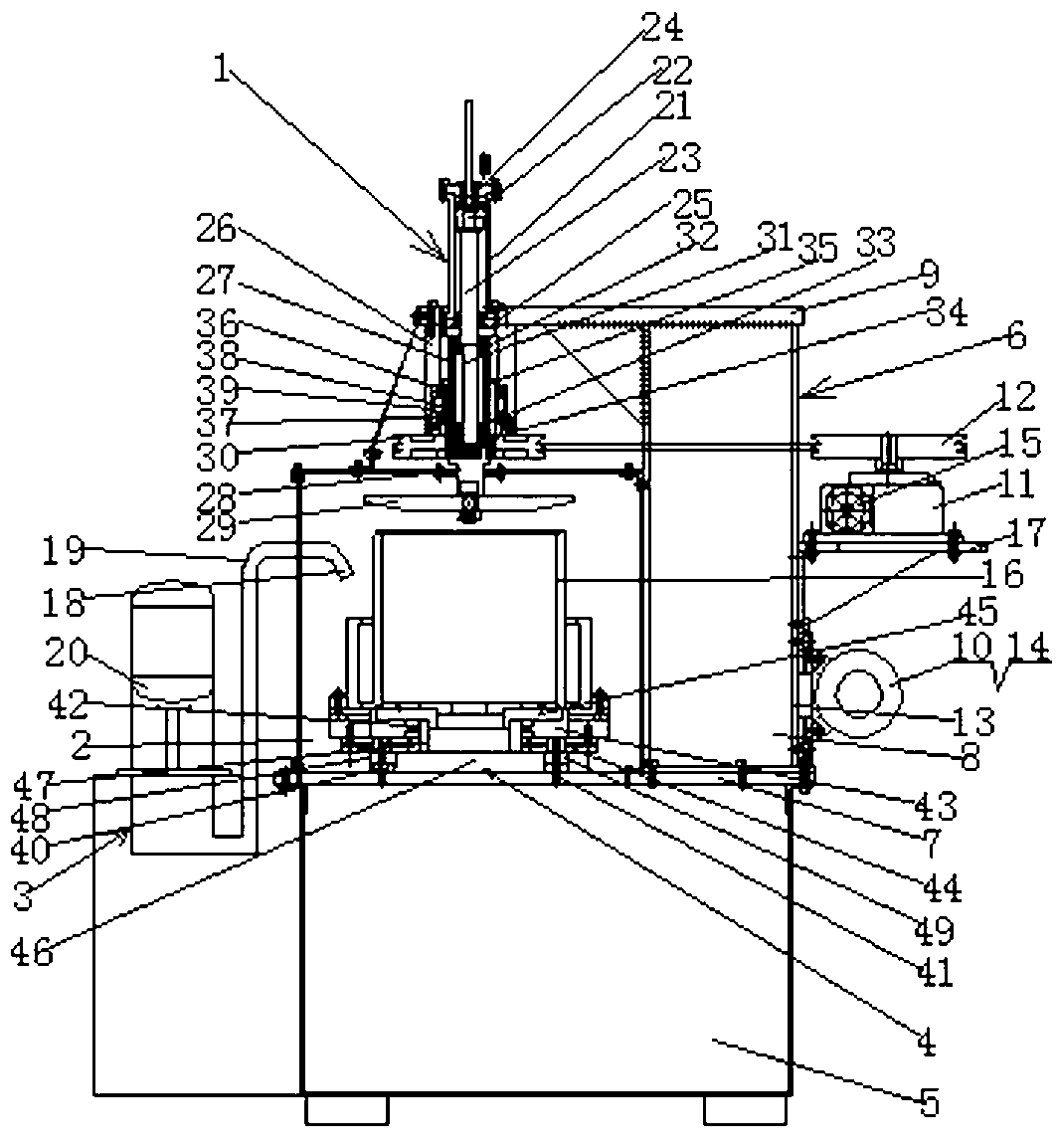

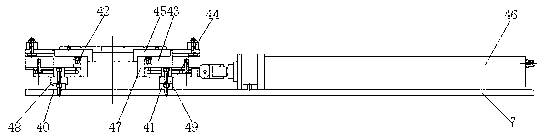

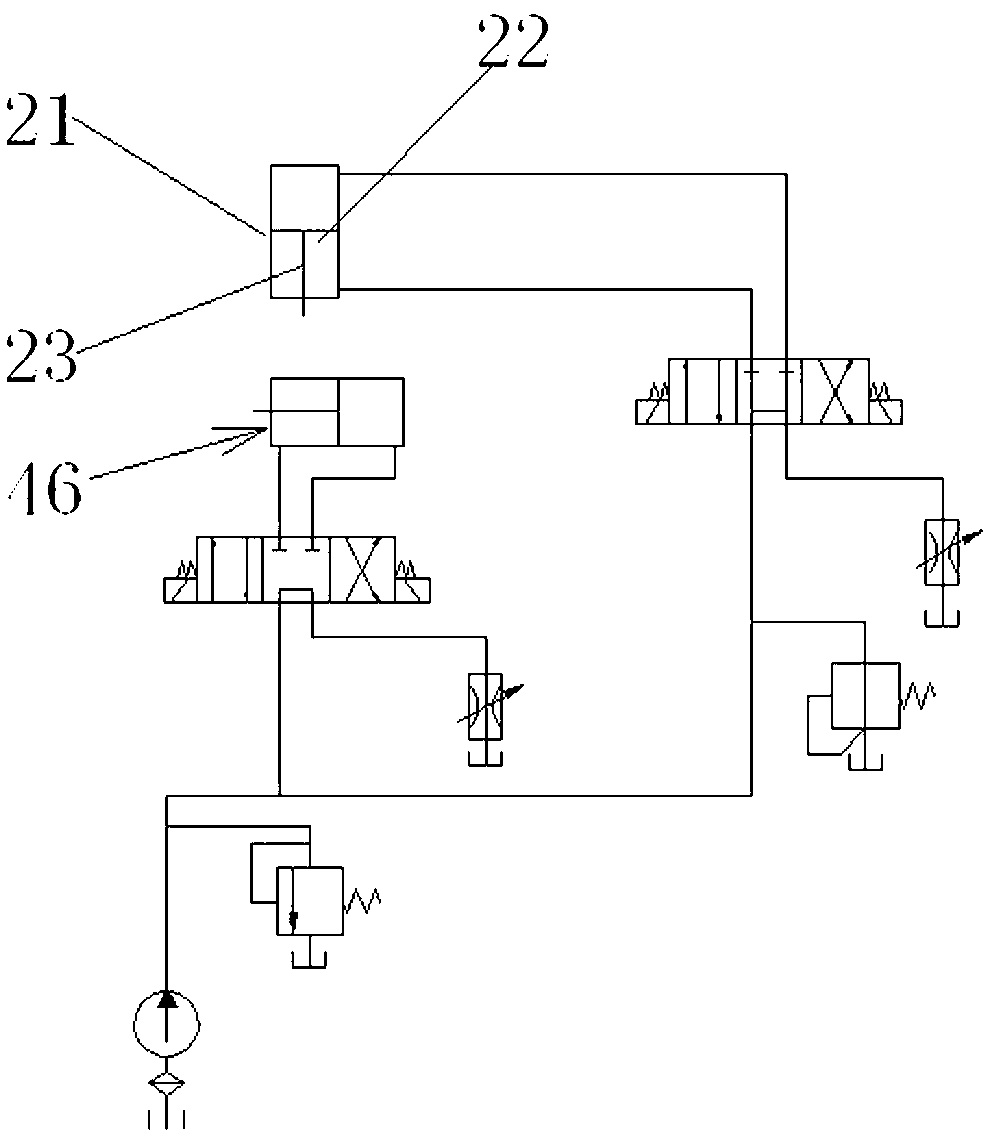

[0024] A press-type cylindrical roller bearing rotary cleaning machine, including a rotary oil cylinder assembly 1, a cleaning room 2, an oil spray mechanism 3, a workbench moving cylinder assembly 4, an oil tank 5, a box-type support 6, and a workbench 7 and power rotation mechanism;

[0025] The box support 6 includes a support box 8 and a support platform 9, the support platform 9 is fixed on the upper end cover of the support box 8, and the lower end of the support box 8 of the box support is fixed on the workbench 7;

[0026] The power transmission mechanism includes a motor 10, a worm gear reducer 11 and a first pulley 12, the motor 10 is fixed on the right side wall 13 of the support box 8, the output shaft of the motor 10 is equipped with a third pulley 14, the worm gear reducer 11 A fourth pulley 15 is installed on the input shaft of the worm gear reducer 11, a first pulley 12 is installed on the output shaft of the worm gear reducer 11, and the third pulley 14 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com