Ultraviolet sterilizer with automatic cleaner

A disinfection device and automatic cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, irradiation, etc., can solve the problems of hard dirt removal, cost reduction, and difficult manufacturing, and achieve simple structure, ensure cleaning effect, Easy to create and install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

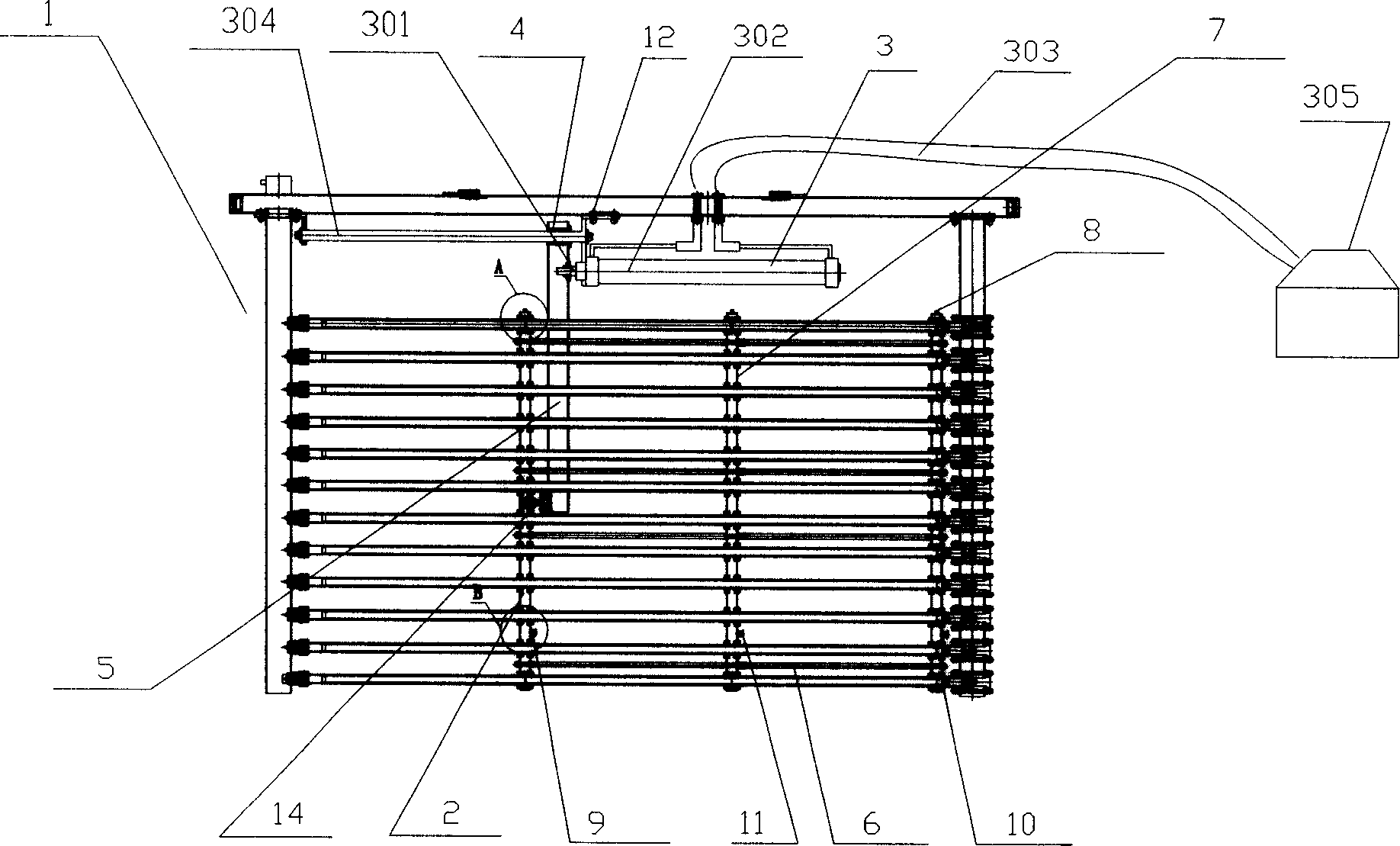

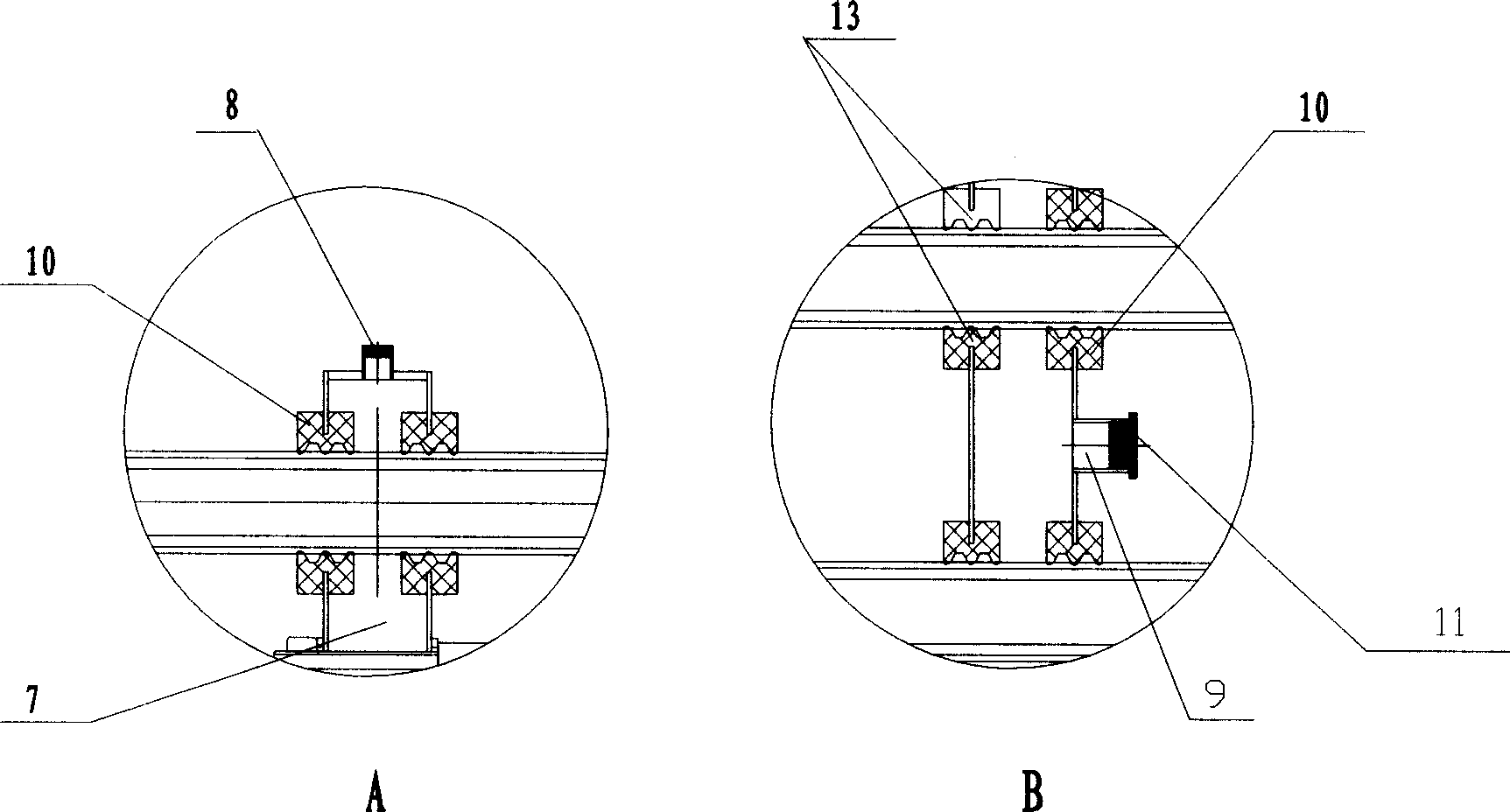

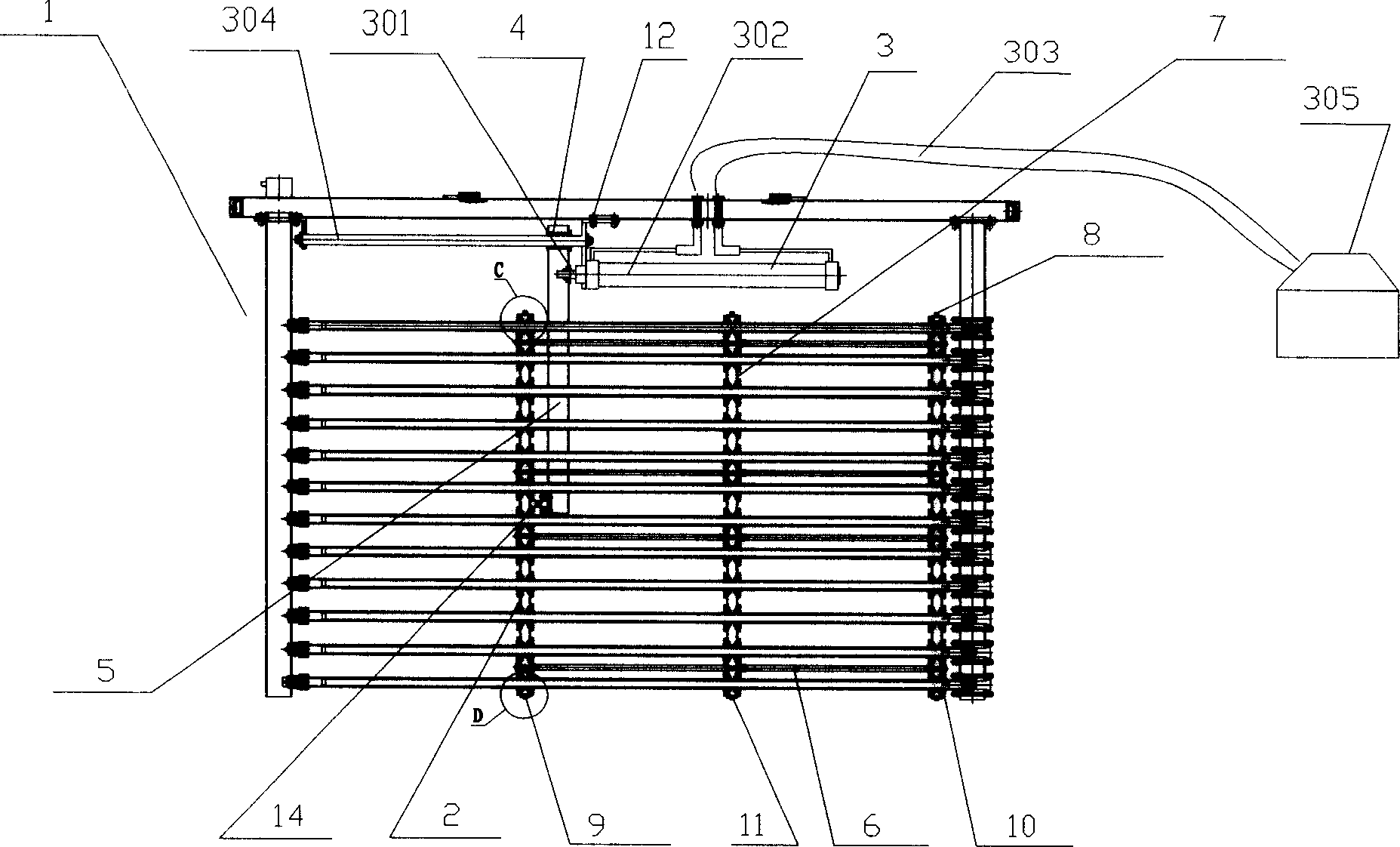

[0019] attached figure 1 , 2 , 3 The first embodiment of the technical solution of the present invention. like figure 1 As shown, the cleaning device 2 of the ultraviolet disinfection system of the present invention includes a scrubbing ring piece 10 , a cleaning solution box 7 , a sliding guide rod 304 , a drag bar 5 and a cleaning device support rod 6 . The cleaning solution box 7 is vertically fixed at the two ends and the middle position of the support rod 6 to form a rectangular cleaning device 2 together with the support rod 6. The cleaning solution box 7 is generally a tube with both ends sealed. On the opposite side of the cleaning liquid box 7, the positions of the same height are provided with several groups of scrubbing ring piercing holes 13 with the same diameter. The cleaning liquid discharge port 9, the cleaning liquid adding port 8 are connected with the cleaning liquid supply pipeline, the cleaning liquid discharge port 9 is sealed with a detachable sealing...

Embodiment approach 2

[0022] attached figure 1 , 2 3. The second embodiment of the technical solution of the present invention is different from the first embodiment in that the cleaning liquid discharge port 9 is arranged on the bottom of the cleaning liquid box 7 in the present embodiment, and the outer side of each scrubbing ring sheet 10 is used A sealing device 15 seals, the gland 1501 is generally ring-shaped, the gland 1501 is provided with a UV lamp tube piercing hole 1502 and an ear hole 1503, and the outer surface of the cleaning liquid box 7 is provided with a gland supporting ring 1505, To ensure that the gland 1501 will not be deformed by force when it is locked, bolts 1504 pass through the ear holes 1503 of the gland 1501 located on both sides of the cleaning solution box 7, and then fix the gland 1501 on the gland support ring 1505 with nuts 1506. lock tight. The cover 1501 presses the scrubbing ring piece 10 tightly on the cleaning solution box 7, so as to enhance the sealing effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com