Laser precise cleaning device and method of part

A cleaning device and laser cleaning technology, applied in the field of laser cleaning, can solve the problems of difficult laser cleaning, uniform and stable control, inability to quickly clean large-area parts, and unsatisfactory cleaning effects, to meet special cleaning requirements and avoid excessive cleaning or cleaning. Insufficient, guaranteed uniformity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

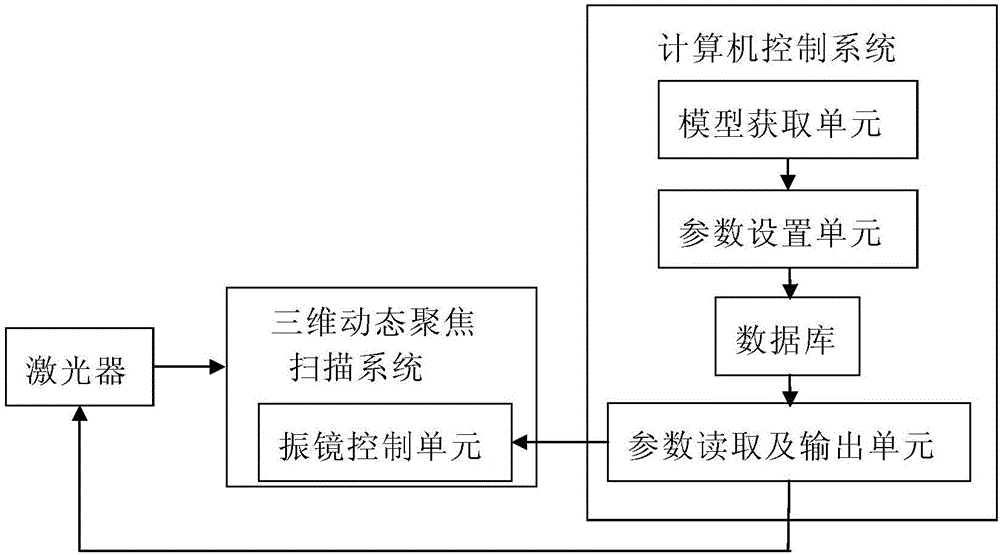

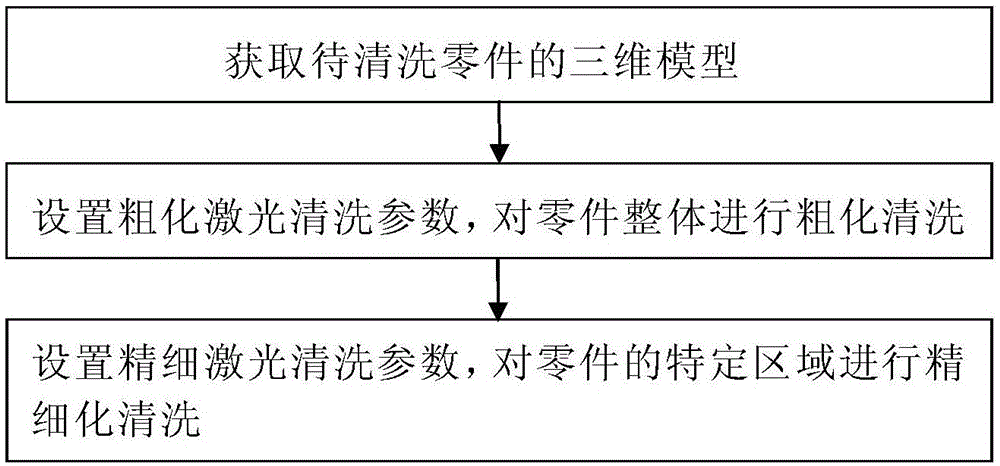

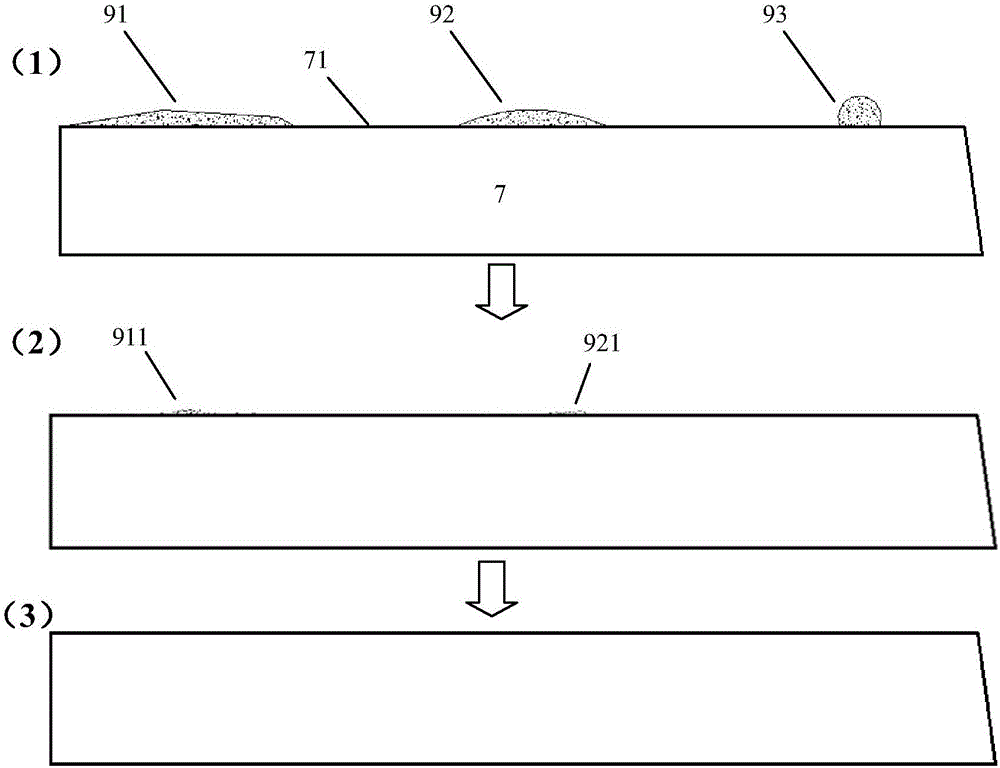

[0033] Such as figure 1 As shown, the laser precision cleaning device for parts disclosed in the present invention includes a laser, a three-dimensional dynamic focusing scanning system, and a computer control system. The three-dimensional dynamic focusing scanning system includes a dynamic focusing mirror group, an X-axis vibrating mirror, a Y-axis vibrating mirror, and a vibrating mirror Control unit, the dynamic focusing lens group includes a Z-axis vibrating mirror and two focusing mirrors; the Z-axis vibrating mirror, two focusing mirrors, X-axis vibrating mirror, and Y-axis vibrating mirror are sequentially arranged on the laser light path emitted by the laser; the vibrating mirror control The units are respectively connected to the servo motors of the X-axis vibrating mirror, Y-axis vibrating mirror, and Z-axis vibrating mirror, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com