Machine for washing zipper heads

A zipper puller and cleaning machine technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of unsatisfactory cleaning quality of zipper pullers, manual handling and cleaning of zipper pullers, and poor surface adhesion Strong and other problems, to achieve the effect of saving resources, reducing labor intensity and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

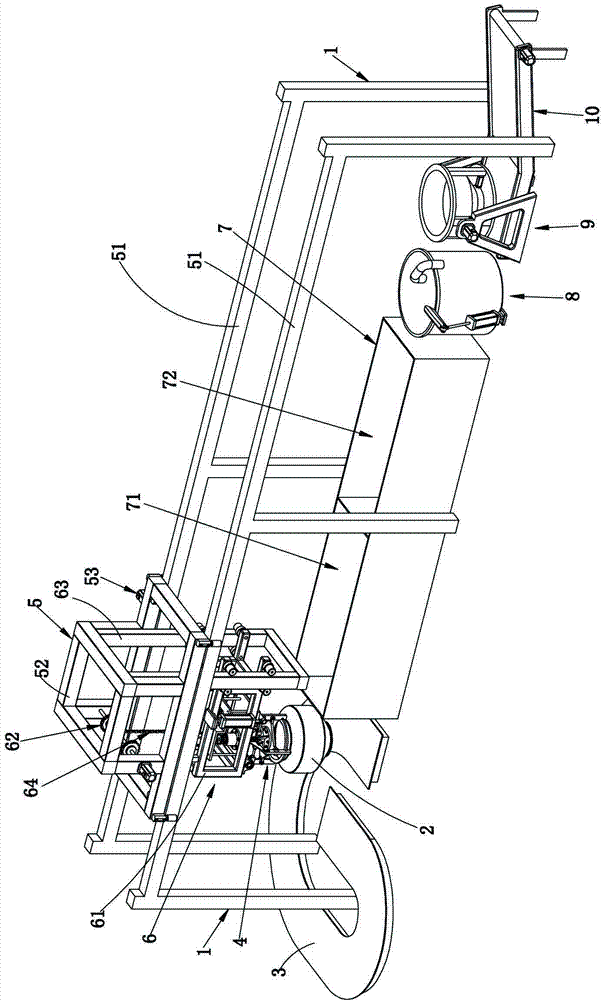

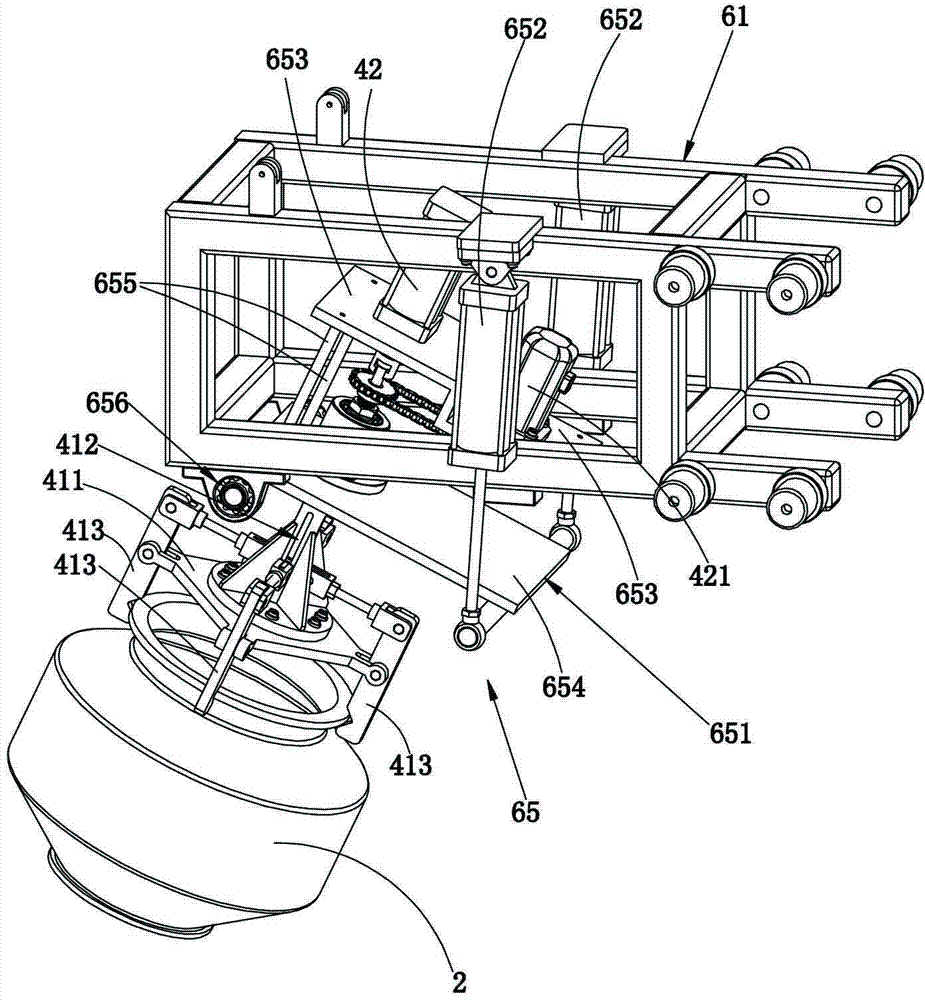

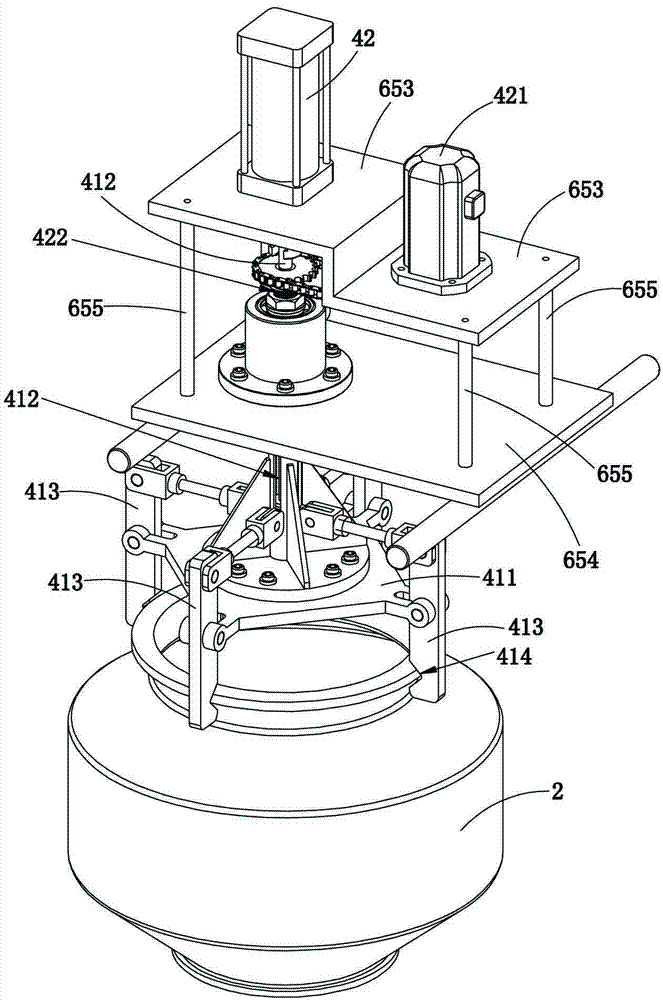

[0023] refer to figure 1 , a zipper puller cleaning machine, including a main frame body 1 and a cleaning bucket 2, the cleaning bucket 2 is used to hold the zipper puller, and also includes a feeding transmission mechanism 3, a clamping mechanism 4, a horizontal moving mechanism 5, a lifting mechanism 6, Cleaning tank 7 and drying mechanism 8. The cleaning tank 7 includes a sulfuric acid tank 71 for containing sulfuric acid and a water tank 72 for containing clear water. The feed conveying mechanism 3, the above-mentioned sulfuric acid tank 71, the above-mentioned water tank 72, and the above-mentioned drying mechanism 8 are discharged in sequence. The feeding conveying mechanism 3 is used for conveying the sliders of the zipper into the above-mentioned cleaning bucket 2 . The drying mechanism 8 is used for drying the zipper sliders in the washing tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com