Electric control system and method for slubby chenille yarn

An electrical control system, chenille yarn technology, applied to spinning machines, textiles and papermaking, continuous winding spinning machines, etc., can solve the problem of low slub twist, prone to delint, uneven yarn twist, etc. Problems, to achieve the effect of not easy to pile up, beautiful appearance, uniform twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

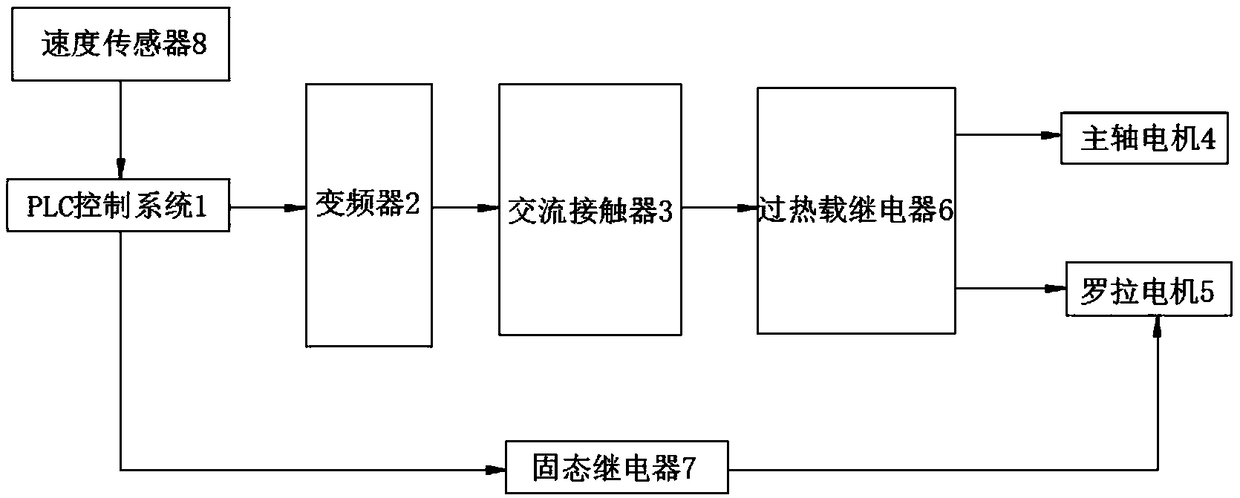

Method used

Image

Examples

Embodiment 2

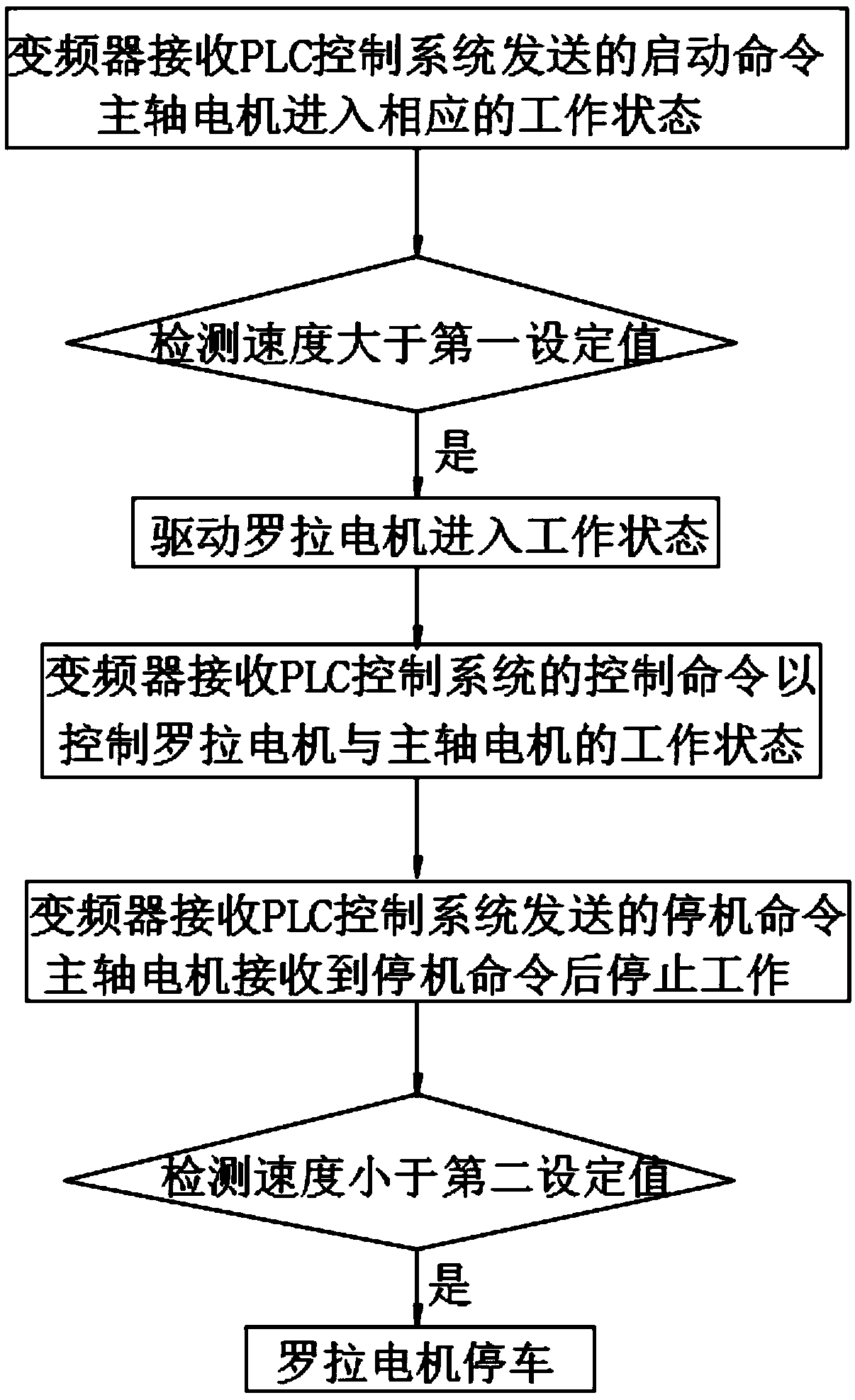

[0046] Such as figure 2 As shown, the present embodiment provides a control method for the slub chenille yarn electrical control system, comprising the following steps:

[0047] S1. The inverter 2 receives the start command sent by the PLC control system 1, and sends the start command to the spindle motor 4, and the spindle motor 4 enters the corresponding working state after receiving the start command;

[0048] S2. The speed sensor 8 detects the speed of the output end of the spindle motor 4, and drives the roller motor 5 to enter the working state when the detected speed is greater than the first set value;

[0049] S3. Frequency converter 2 receives the control command of PLC control system 1 to control the working state of roller motor 5 and spindle motor 4;

[0050] S4. The frequency converter 2 receives the shutdown command sent by the PLC control system 1, and sends the shutdown command to the main shaft motor 4, the main shaft motor 4 stops working after receiving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com