Production method and forming device for cylindrical reconstituted bamboo lumber

A technology for recombining bamboo and forming devices, which can be applied to other household appliances, wood processing appliances, household components, etc., can solve the problem of not being able to meet the requirements for the production of imitation wood-grain recombined decorative materials. Bulk material and other issues, to achieve the effect of saving bamboo resources, low pressure, low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

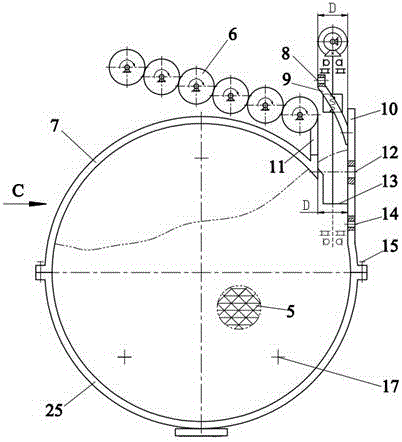

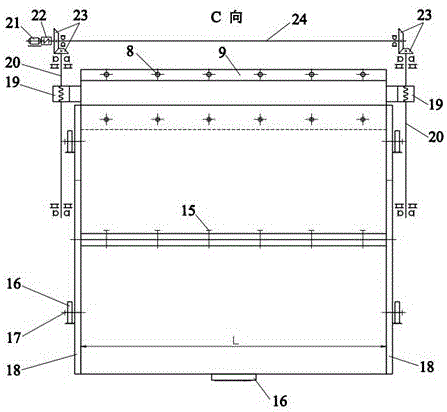

[0021] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing:

[0022] This cylindrical body recombined material forming device includes a frame 16, a material pressurization system, a barrel-shaped mold, and a driving roller group 6. The barrel-shaped mold is composed of a semicircular arc-shaped upper template 7 and a semicircular arc-shaped lower template 25 and two The circular end cover 18 at the end is composed of a cylindrical inner cavity, and the upper formwork has a square window with a width D and a length ≥ L, and each of the two long sides of the square window is parallel to each other and installed vertically on the ground. The guide plates 10 and 11, the distance between the inner walls of the two guide plates is D, and there is an arc-shaped pressure plate 9 between the two guide plates, which together form a vertical feeding channel. The upper template and the lower template are fixed by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com