Magnetic suction mechanism

A material suction mechanism and magnetic technology, applied in conveyors, conveyor objects, rotary conveyors, etc., can solve problems such as magnetic dispersion, poor directionality, and unloading steel bar failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

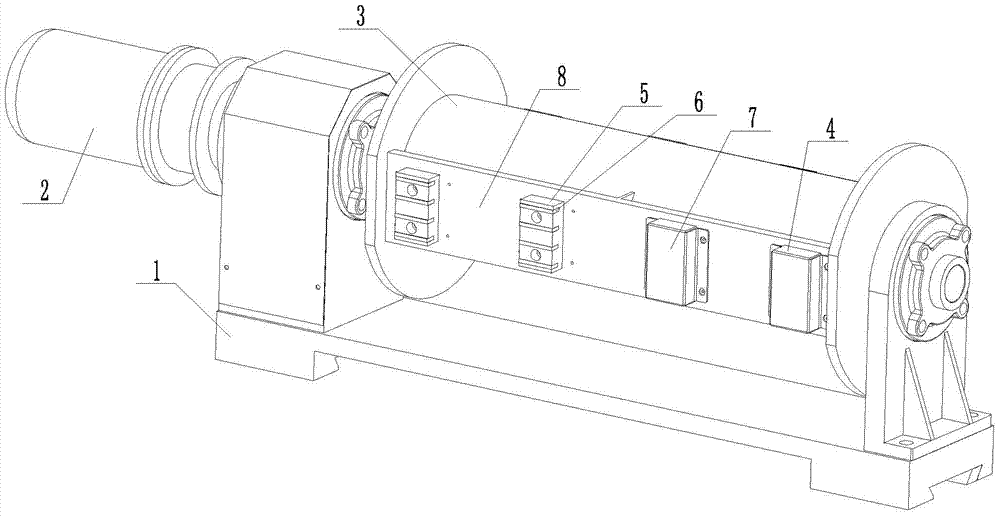

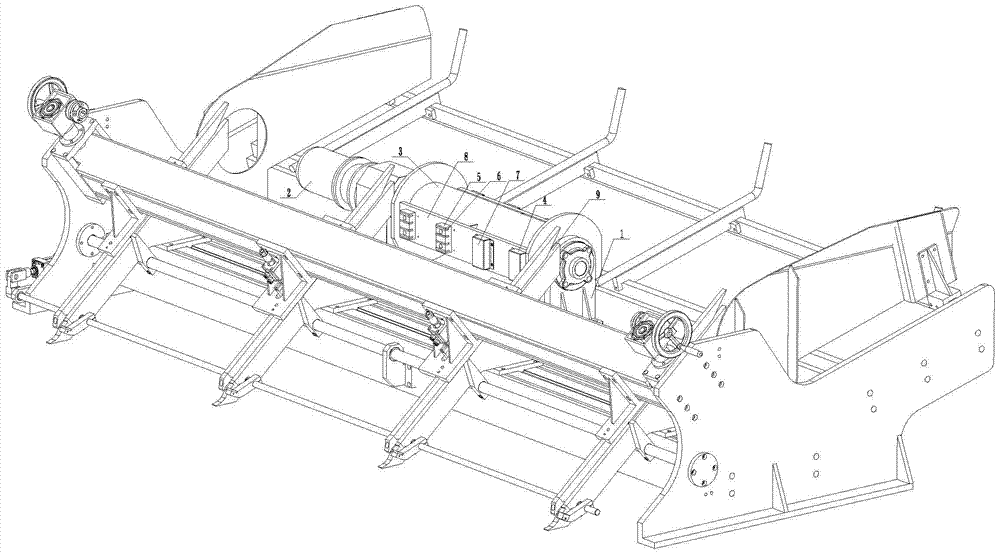

[0013] The magnetic suction mechanism of the present invention includes a frame 1, a motor 2 and a drum 3, and it also includes a plurality of columns of magnetic units, each column of which is evenly distributed along the circumferential direction of the drum 3, and each magnetic unit 4 in each column of magnetic units Evenly distributed along the axial direction of the drum 3; the magnetic monomer 4 includes a bracket 5 made of antimagnetic material, a plurality of magnets 6, a cover 7 made of a magnetically permeable antimagnetic material, and the bracket 5 is connected to the cylindrical surface of the drum 3, A plurality of magnets 6 are uniformly arranged on the bracket 5 from top to bottom, and a cover 7 covers the bracket 5 to cover the plurality of magnets 6 .

[0014] The cylindrical surface of the drum 3 is provided with axially arranged supporting platforms 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com