Composite material for visible light catalysis, preparation method thereof and application thereof in water treatment

A composite material and visible light technology, which is applied in special compound water treatment, light water/sewage treatment, energy wastewater treatment, etc., can solve the problems of difficult post-processing, unfavorable recycling and repeated use, and achieve the reduction of synthesis steps and operation difficulty, Realize the effect of catalytic performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

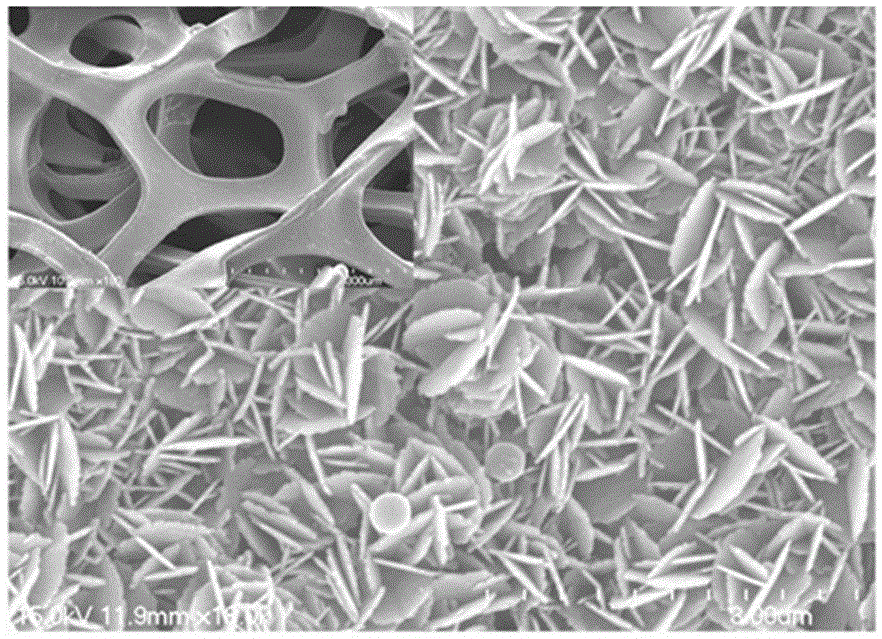

[0032]Preparation of bismuth oxyiodide oxide nanosheet-loaded metal nickel foam composite (Ni foam@BiOI): Dissolve 0.02 mmol of bismuth nitrate pentahydrate and 0.02 mmol of potassium iodide in 10 mL of absolute ethanol solution at room temperature, respectively, and denoted as solution A 1 and solution B 1 , put A 1 Solution and B 1 The solution was mixed and stirred for 30 minutes, then transferred to a 25 mL hydrothermal reactor, and 50 mg of metallic nickel foam was added to the reactor, and reacted at 180 °C for 12 h. After the reaction was finished, the reactor was naturally cooled to room temperature and then opened. The metal nickel foam was clamped out with tweezers, rinsed twice with deionized water and 95% ethanol respectively, and dried in a vacuum oven for 6 h to obtain Ni foam@BiOI. figure 1 It is the scanning electron microscope image of BiOI supported on nickel foam, and the inset in the upper left corner is the scanning electron microscope image of uncompos...

Embodiment 2

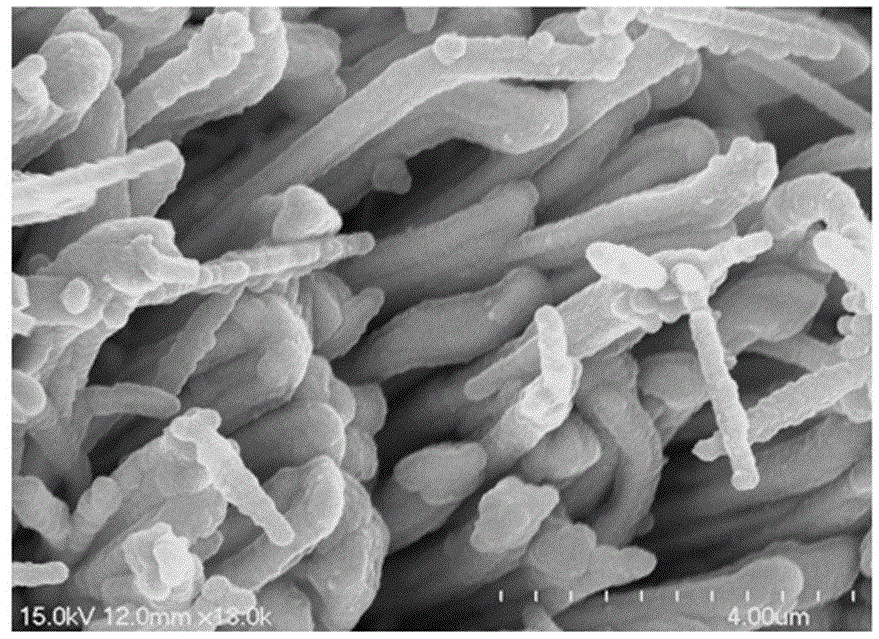

[0034] Preparation of bismuth oxyiodide nanorod-supported metal nickel foam composite (Ni foam@BiOI): At room temperature, 0.02 mmol of bismuth nitrate pentahydrate and 0.02 mmol of potassium iodide were dissolved in 10 mL of ethylene glycol, respectively, and recorded as Solution A 2 and solution B 2 , put A 2 Solution and B 2 The solution was mixed and stirred for 30 minutes, then transferred to a 25 mL hydrothermal reactor, and 50 mg of metallic nickel foam was added to the reactor, and reacted at 180 °C for 12 h. After the reaction was finished, the reactor was naturally cooled to room temperature and then opened. The metal nickel foam was clamped out with tweezers, rinsed twice with deionized water and 95% ethanol respectively, and dried in a vacuum oven for 6 h to obtain Ni foam@BiOI. figure 2 It is the SEM image of BiOI supported on nickel foam.

Embodiment 3

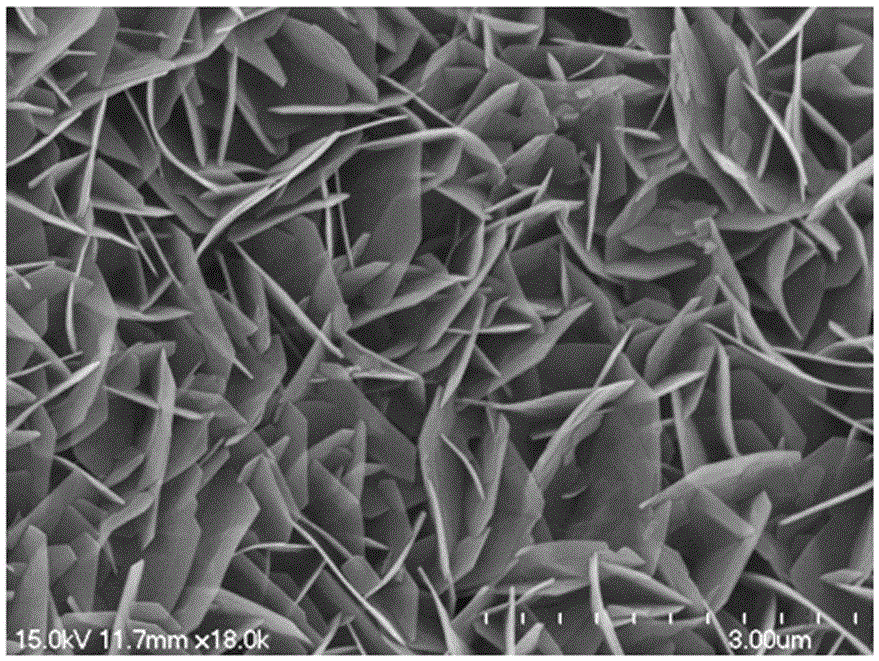

[0036] Bismuth oxyiodide / bismuth oxychloride binary composite loaded metal nickel foam composite (Ni foam@BiOI 0.5 Cl 0.5 ) preparation: Weigh 0.02 mmol of bismuth nitrate pentahydrate and dissolve it in 10 mL of absolute ethanol, denoted as A 3 ; Weigh 0.01 mmol potassium iodide and 0.01 mmol potassium chloride and dissolve in 10 mL absolute ethanol solution and record it as solution B 3 , put A 2 Solution and B 2 The solution was mixed and stirred for 30 minutes, then transferred to a 25 mL hydrothermal reaction kettle, and then 50 mg of metal nickel foam was added to the reaction kettle, and reacted at 180 °C for 12 h. After the reaction, the reactor was naturally cooled to room temperature and opened, and the metal nickel foam was clamped out with tweezers, rinsed twice with deionized water and 95% ethanol respectively, and dried in a vacuum oven for 6 h to obtain Ni foam@BiOI 0.5 Cl 0.5 , with image 3 Is BiOI 0.5 Cl 0.5 SEM images of Ni foam loaded on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com