Washing method of water tank type washing machine with bubble washing basket

A sink type cleaning machine and bubble cleaning technology, applied in application, food processing, food science and other directions, can solve the problems of weak rotating power, poor cleaning of fruits and vegetables, poor cleaning effect of fruits and vegetables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

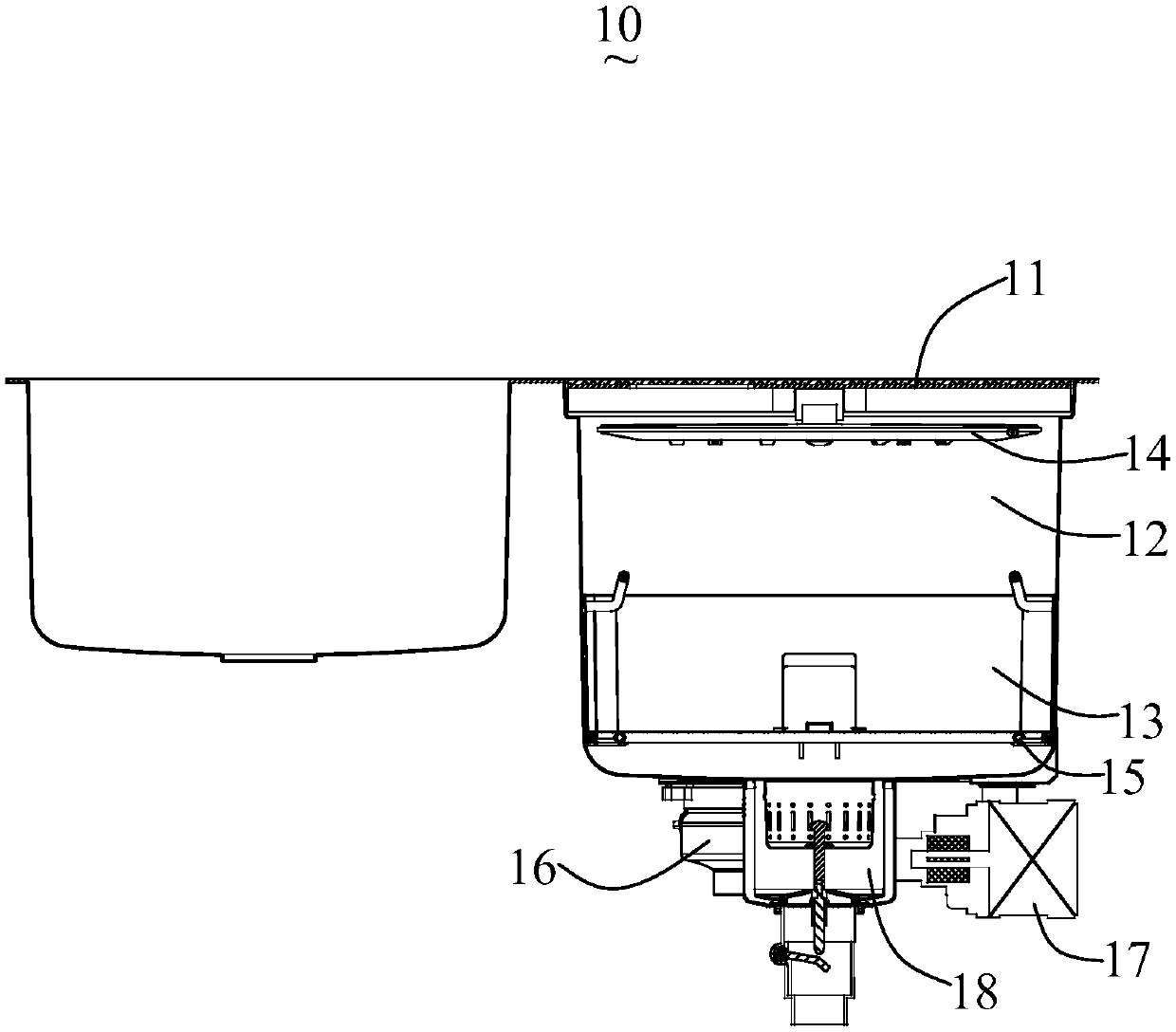

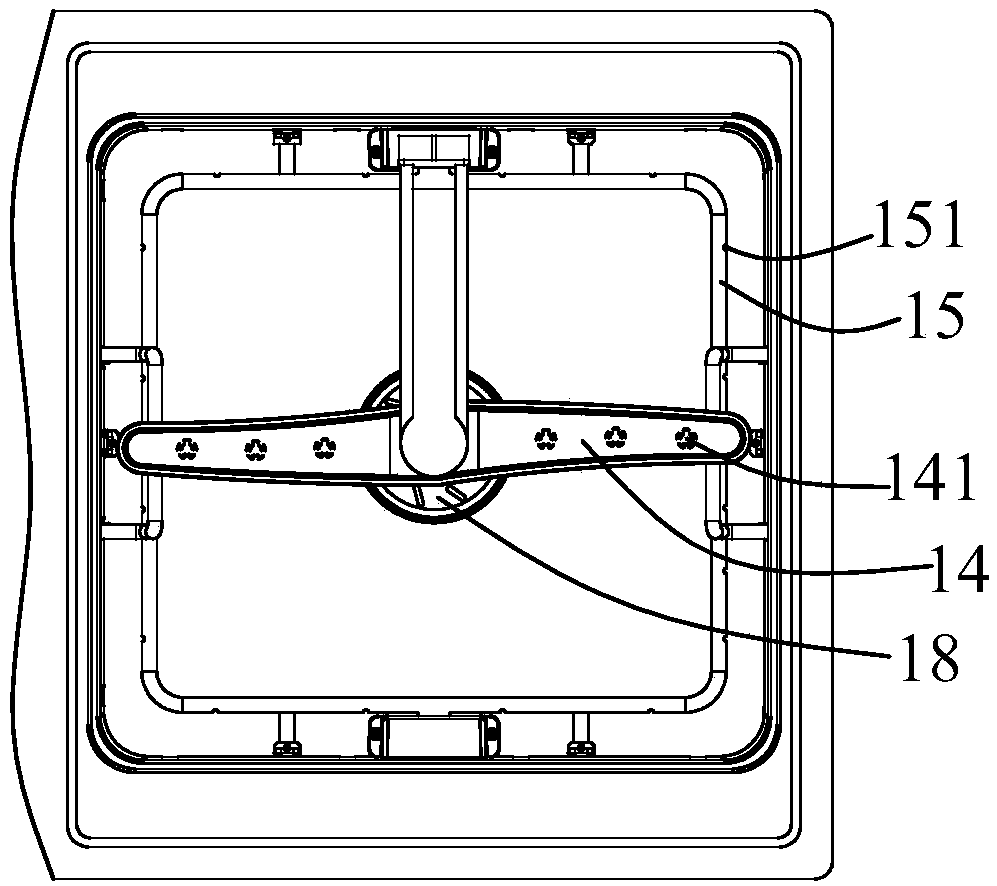

[0036] see figure 1 and figure 2 The schematic diagram of the first preferred embodiment of the sink type cleaning machine with bubble cleaning basket, the sink type cleaning machine 10 with bubble cleaning basket includes a cover body 11, a sink 12, and a cleaning basket accommodated in the sink 12 13 and the rotating spray arm 14, the cover body 11 closes the opening of the water tank 12, the bottom of the cleaning basket 13 is provided with a first air guide channel 15, the first air guide channel 15 is provided with an air outlet 151, and the outside of the water tank 12 is provided with Air pump 16, the first air guide channel 15 communicates with the air pump 16, the rotating spray arm 14 rotates relative to the water tank 12, and the spray hole 141 on the rotating spray arm 14 is arranged in the first air guide channel 15 The distance between the first air guide channel and the inner wall of the sink is 5 to 50 mm. When it is less than 5 mm, the cleaning basket is too...

Embodiment approach 2

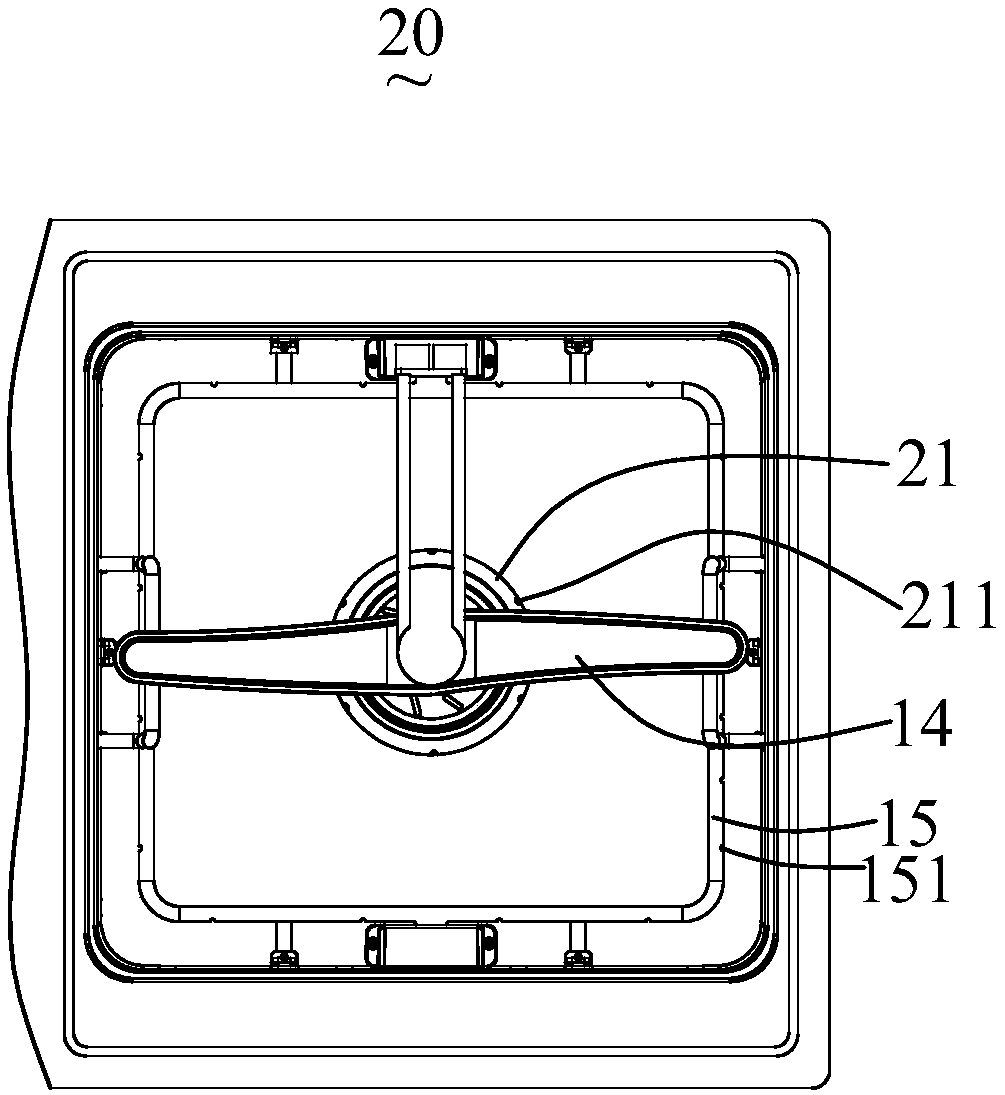

[0049] see image 3 The schematic diagram of the second preferred embodiment of the sink type cleaning machine with the bubble cleaning basket, the difference between the sink type cleaning machine 20 with the bubble cleaning basket and the sink type cleaning machine 10 with the bubble cleaning basket is: Also includes a second air guide channel 21, the second air guide channel 21 communicates with the air pump 16, the projection of the second air guide channel 21 is within the projection of the area swept by the rotation of the rotating spray arm 14, the second guide air channel The air outlet hole 211 on the air channel 21 is 1 / 5 to 1 / 10 of the air outlet hole 151 on the first air guide channel 15. When the rotating spray arm 14 is in the rotation process, the water flow is easy to form a vortex in the center, and some fruits and vegetables are easy to vortex. Rotating in the vortex, by setting the second air guide channel 21, the fruits and vegetables in the vortex can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com