Efficient combined desulfurization and denitrification device and method

A high-efficiency technology for desulfurization and denitrification, applied in the field of denitrification and desulfurization, can solve the problems affecting the denitrification and desulfurization efficiency of exhaust gas, affecting the efficiency of denitrification and desulfurization, and the frequency of adsorbent replacement, etc. Effect, move change effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

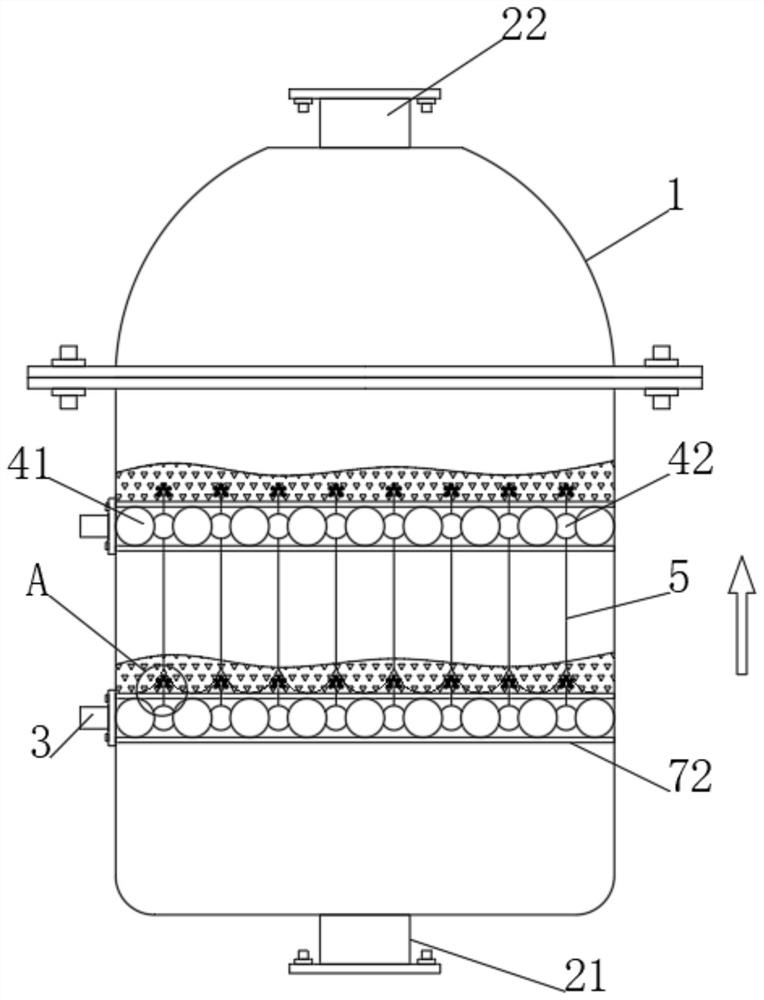

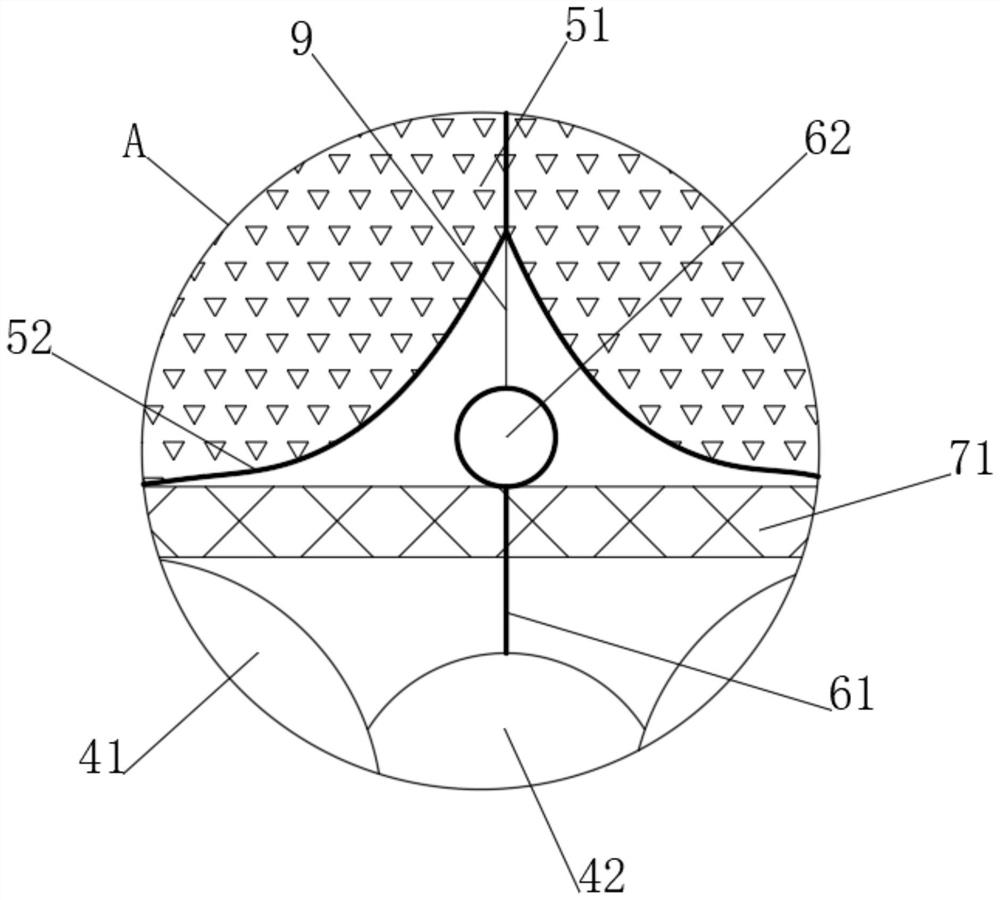

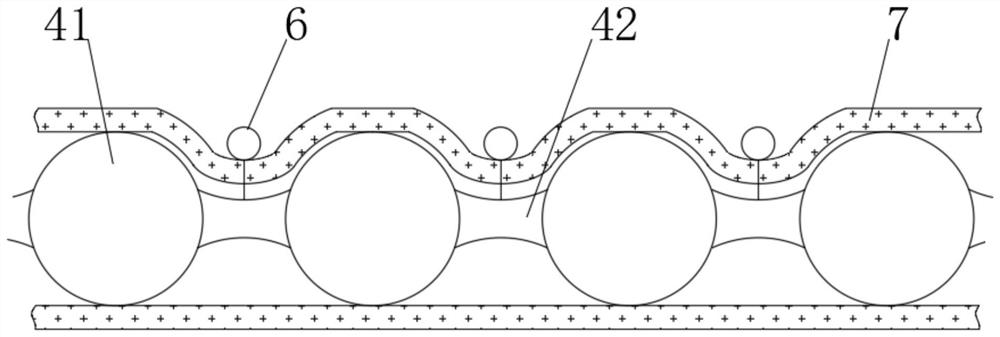

[0045] see Figure 1-2 , the arrow in the figure indicates the running direction of exhaust gas. A high-efficiency combined desulfurization and denitrification device includes a device body 1, and the upper and lower ends of the device body 1 are respectively fixedly connected with an air outlet 22 and an air inlet 21, and the air outlet 22 and the air inlet 21 They are all connected to the interior of the device body 1. There are multiple sets of double-layer pneumatic filter screens inside the device body 1. Adsorbent particles are laid on the top of the double-layer pneumatic filter screen. The left end of the device body 1 is fixedly connected with multiple sets of double-layer pneumatic filter screens The two-way air port 3 of the double-layer pneumatic filter screen is provided with an upwardly protruding lotus leaf bar 5 between two adjacent groups of double-layer pneumatic filter screens. The bulb plate between the variable net 71 and the lower fixed net 72, the two-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com