Engine cylinder body full-automatic vertical electro brush plating equipment

An engine block, fully automatic technology, applied in the field of electric brush plating equipment, can solve problems such as error-prone liquid mixing, affecting the rhythm, reducing efficiency, etc., to achieve the effect of improving the degree of cleaning, saving time, and increasing the coating layer quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

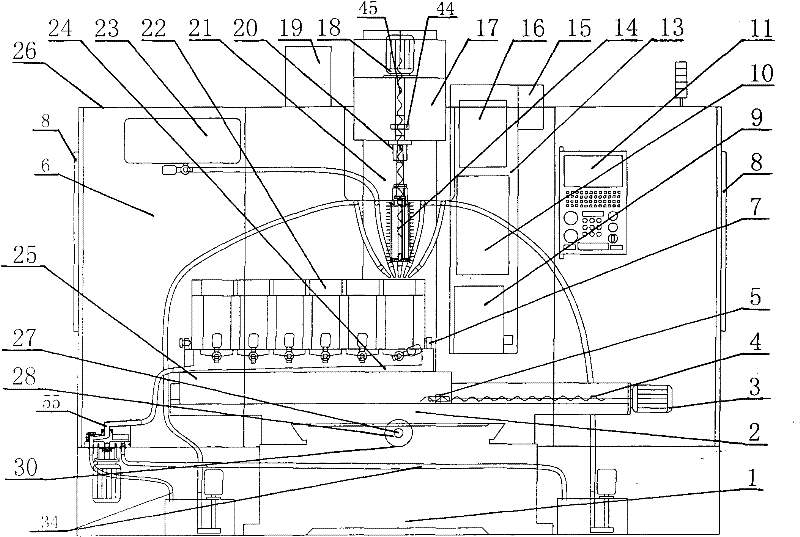

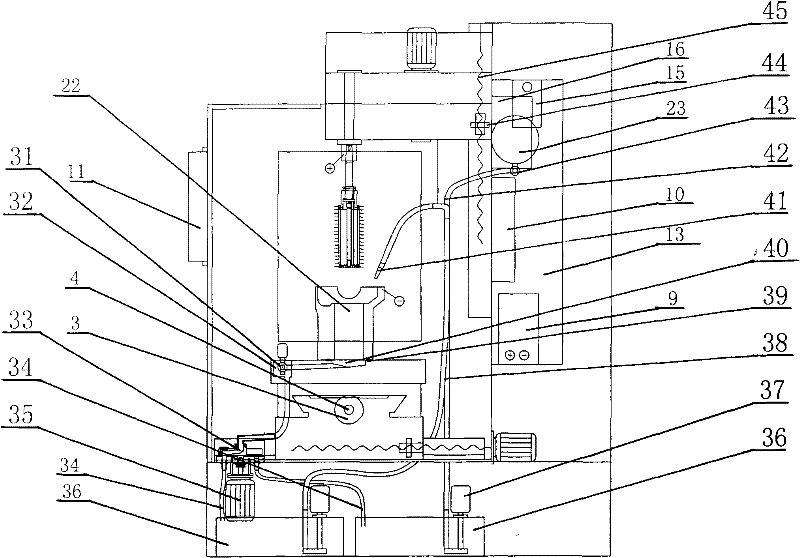

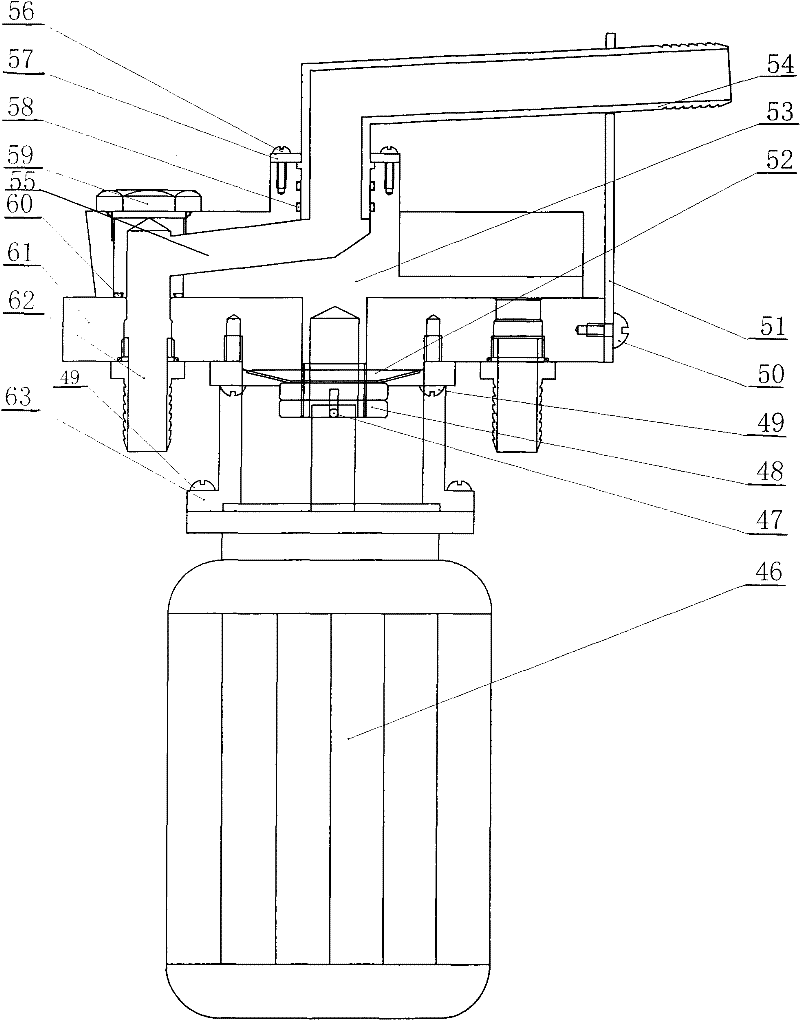

[0046] Such as Figure 1-7 As shown, the body 1 is the supporting base of the brush plating center, and is equipped with a Y guide rail motor 30 and a Y guide rail screw 27 connected to the XY two-dimensional guide rail 2 through the Y guide rail nut 28 . The X guide rail motor 3 and the X guide rail lead screw 4 fixed on the XY two-dimensional guide rail 2 are connected to the two-dimensional brushing platform 25 through the X guide rail nut 5 . The insulating platform 24 is fixed on the upper plane of the two-dimensional brush-plating platform 25 , and the positioning block 7 on the upper plane of the insulating platform 24 is used to position the workpiece 22 . The control panel 11 controls the Y rail motor 30 and the X rail motor 3 through the microcomputer 16 and the program-controlled electrical appliance 10 to align the workpiece 22 with the brush plating pen 14 . The Z guide rail column 21 is perpendicular to the XY two-dimensional guide rail 2 and rigidly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com