Cotton high-strong fiber gene major gene site and moloecular labelling thereof

A technology of main effect genes and high-strength fibers, applied in the field of discovery and utilization of new genetic resources, can solve the problems of high cost, difficulty, and slow progress in quality breeding, and achieve the goals of improving fiber quality, accelerating industrialization, and improving selection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

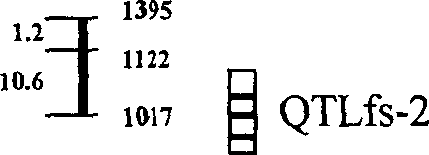

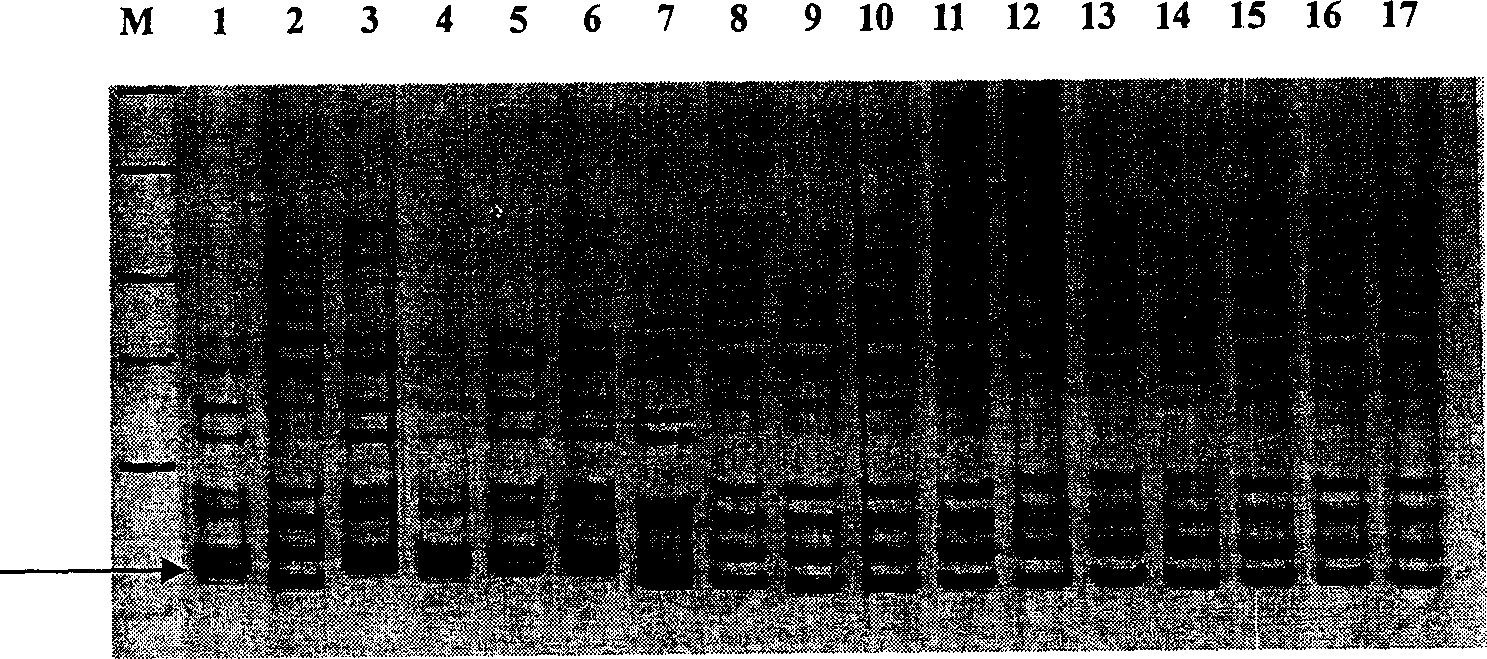

[0031] The implementation procedure of the present invention is: the upland cotton high-strength fiber germplasm line HS427-10 introduced from the Crop Germplasm Resources Laboratory of the Southern Plains Research Center of the United States Department of Agriculture is selected for individual plants, and the fiber quality is measured, and the homozygous and stable ones are selected. Strain HS427-10, according to the measurement results in 2000 and 2001, the average fiber quality of strain HS427-10 in two years is: fiber strength 42.3g / tex, fiber length 32.6mm, fiber fineness 5.18, upland cotton genetics The standard line TM-1 (American Daizi cotton 14 varieties self-crossed for more than 15 generations, provided by Dr. Kohel of the Southern Plains Agricultural Research Center of the Department of Agriculture, University City, Texas, USA) is: fiber strength 31.33g / tex, fiber length 30.7mm, fiber fineness 5.39.

[0032] In 1999, the strain HS427-10 was crossed with TM-1, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fiber strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com