Industrial production of natural cocoon sheet and method of in situ processing natural cocoon silk quilt

A natural silk, industrialization technology, applied in the field of industrial production of natural cocoon beating cotton sheets, on-site processing of natural silk quilts, can solve the lack of transparency in the understanding of quality grades, hygienic conditions, the inability to directly understand the processing process of silk quilts, and the thickness of silk quilts Unevenness and other problems, to achieve the effect of easy after-sales service, protection of the right to know, and simple and easy process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings and preferred embodiments.

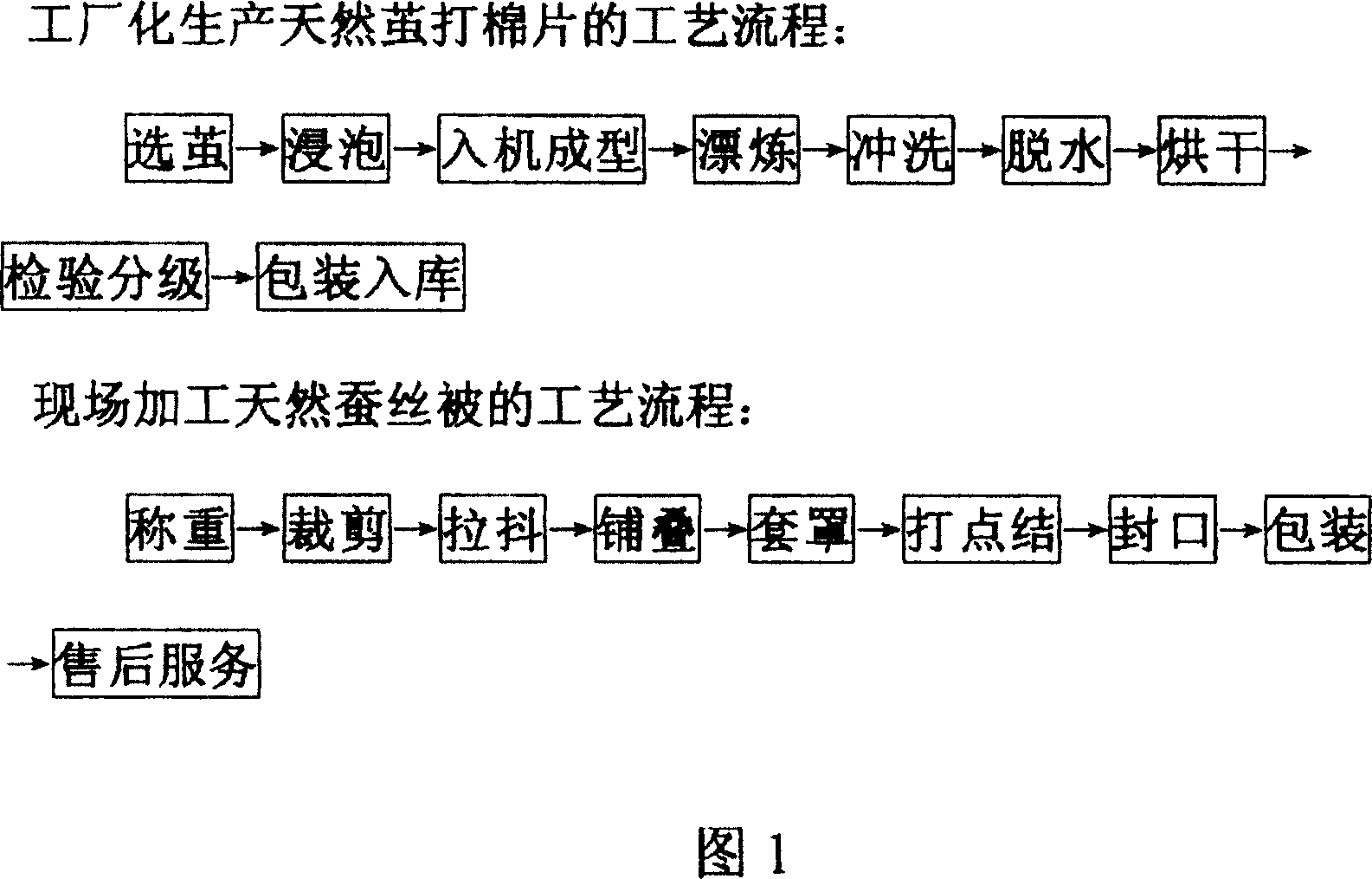

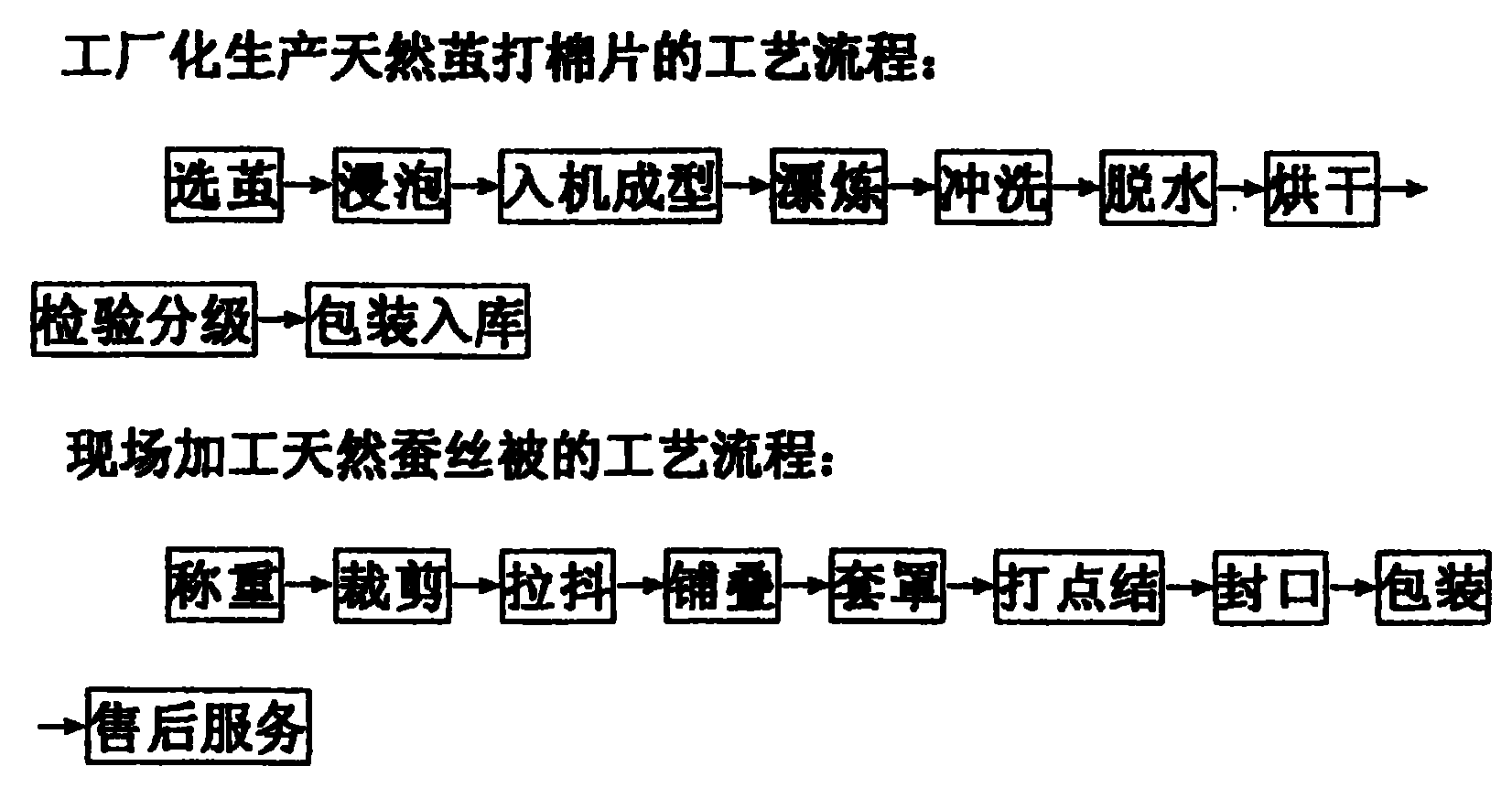

[0033] Referring to Figure 1, a method for factory production of natural cocooned cotton sheets and on-site processing of natural silk quilts includes two process steps: factory production of natural cocooned cotton sheets and on-site processing of natural silk quilts. The factory of the present invention The production of natural cocoon-made cotton sheets mainly includes the process steps of cocoon selection, soaking, molding, bleaching, washing, dehydration, drying, inspection and classification, packaging and storage, etc.

[0034] Cocoon selection: select the silkworm cocoons according to the grade standard, generally choose the color and luster of white, clean, large and thick fine silkworm cocoons;

[0035] Soaking: Soak the selected silkworm cocoons in warm water in the pool, the general water temperature is 40-60℃, and the soaking time is 40-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com