Technique for preparing multifunctional liner of printing sarcenet

A production process and multi-functional technology, which is applied in the fields of clothing, clothing, textiles and papermaking, etc., can solve the problems affecting the feel and appearance of fabrics, and achieve the effect of good drapability, excellent elasticity and strength, and bulky and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

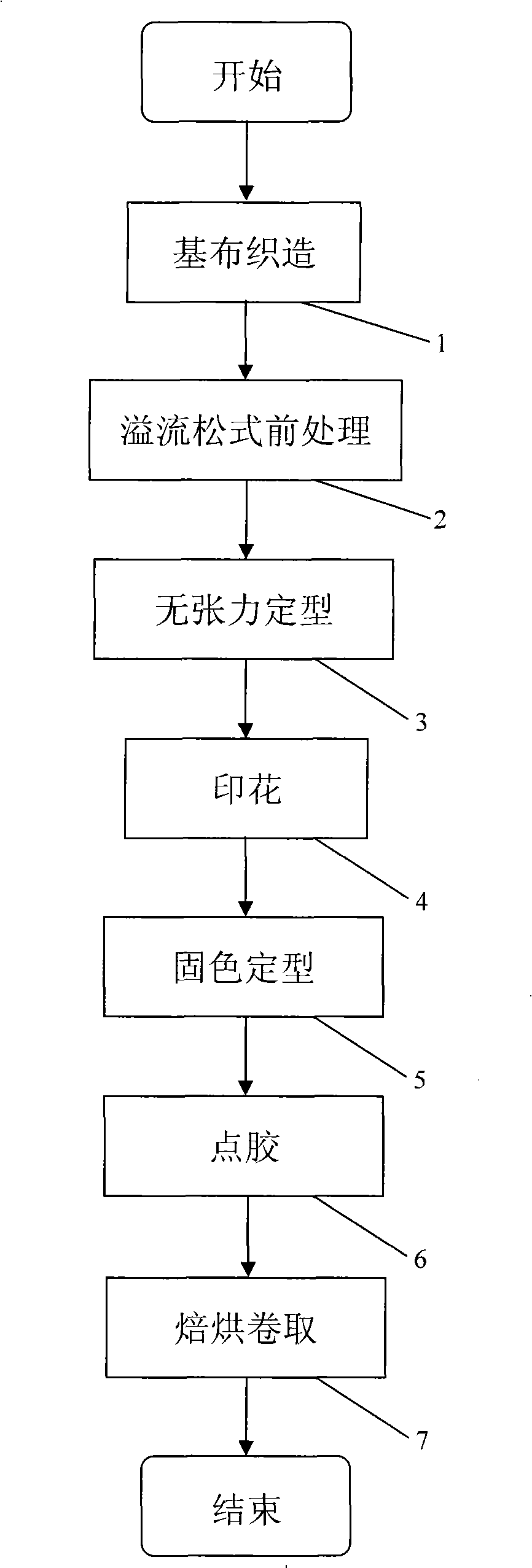

[0019] refer to figure 1 , a kind of production technology of multifunctional lining of printed lining, comprises the following steps successively:

[0020] Base fabric weaving 1: The base fabric is made of 50D / 48F synthetic filaments, and is woven by a fully automatic jet machine. Overflow loose pre-treatment 2: The woven base fabric is subjected to loose pre-treatment through a high-temperature and high-pressure overflow machine. Set the nozzle pressure to 0.2-0.5kg / m 3 , the temperature is 100°C-120°C, and the residence time is 30-45 minutes.

[0021] Because the fabric is thin and easy to snag, not only high requirements are placed on the equipment during the processing, but also the process formula and process are very critical. By using the computer on the high-temperature and high-pressure overflow machine to precisely control the temperature, time, and nozzle pressure, the cloth surface is smooth, clean, and free of snags.

[0022] Tension-free shaping 3: The base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com