Tool storage bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

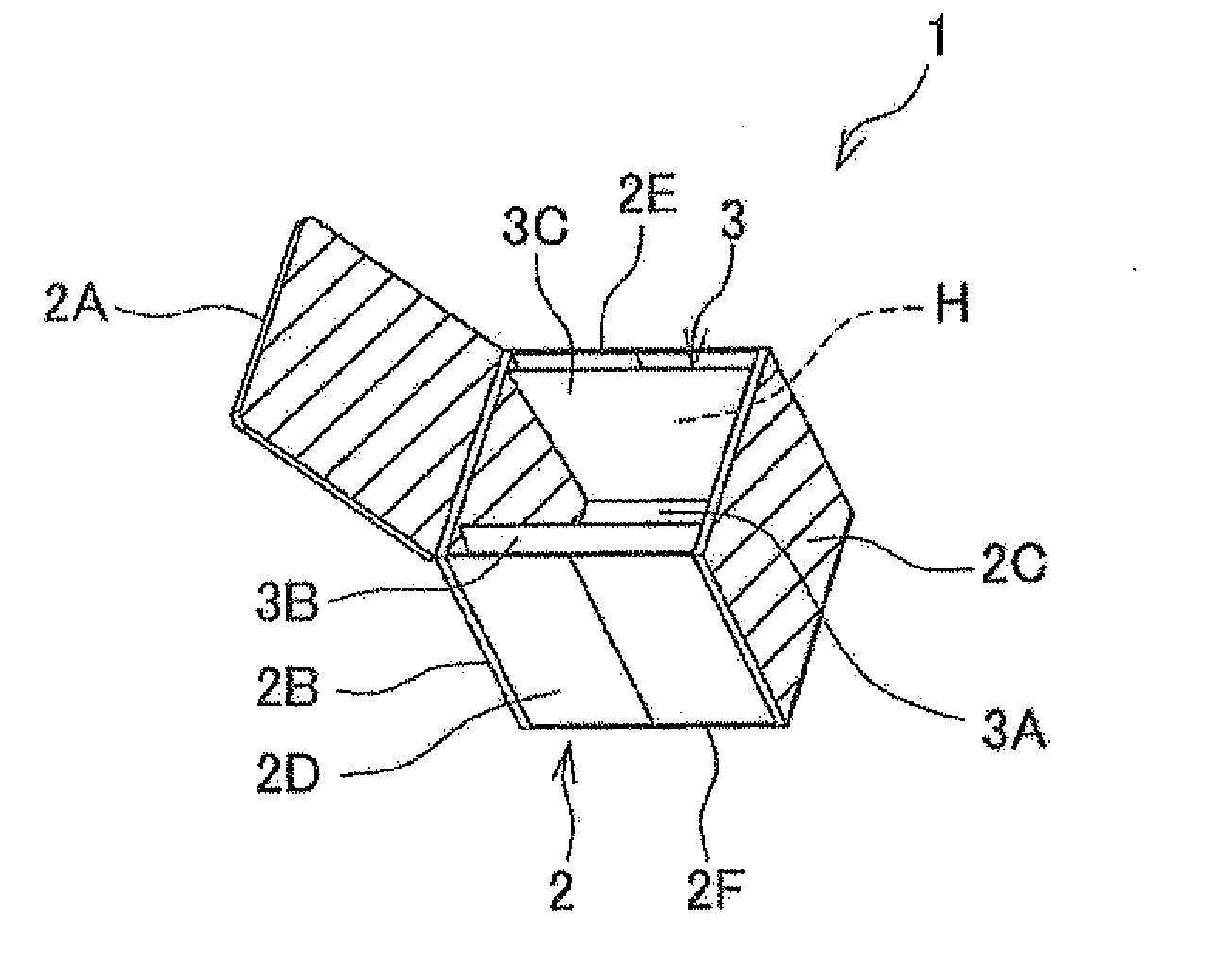

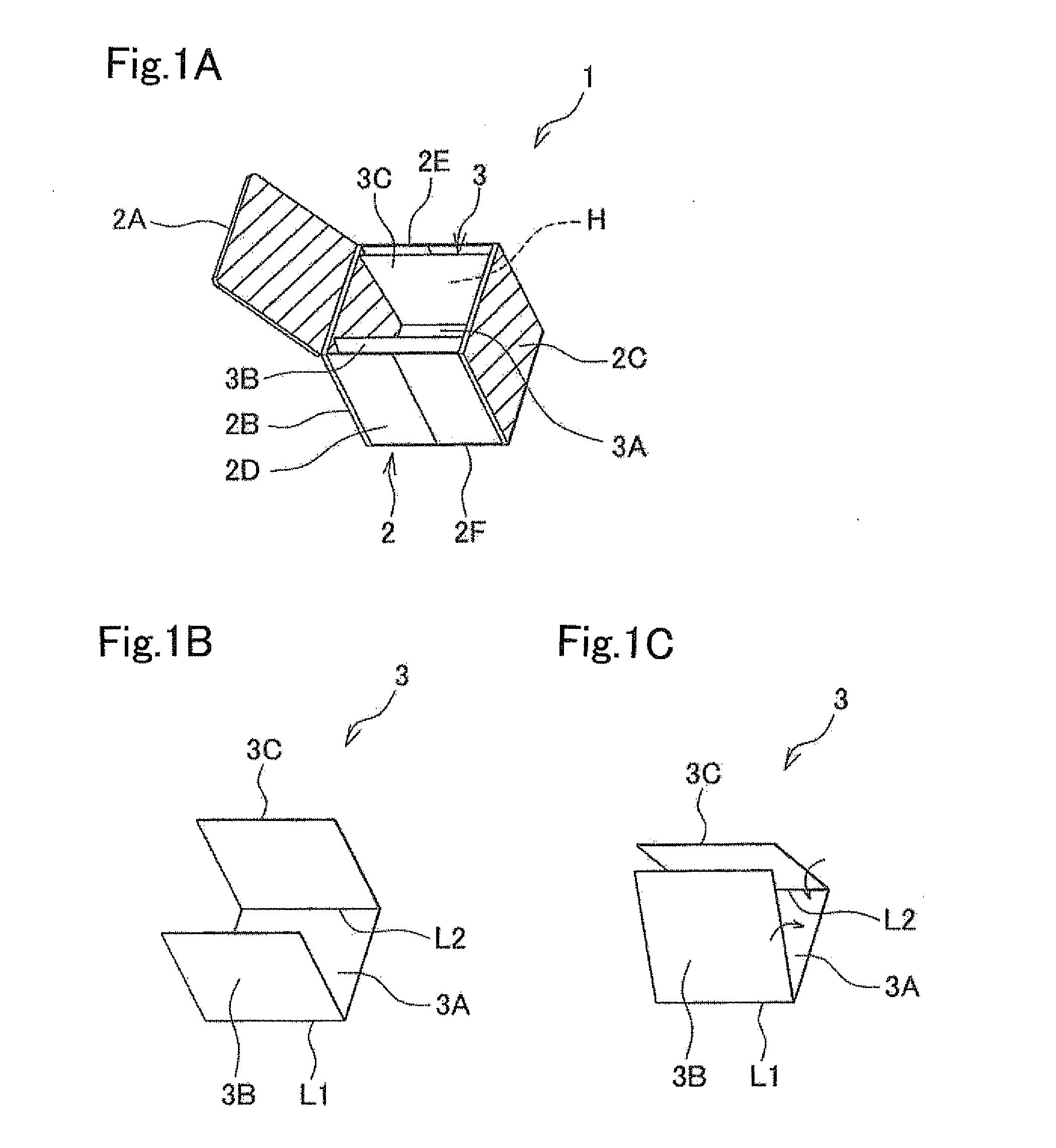

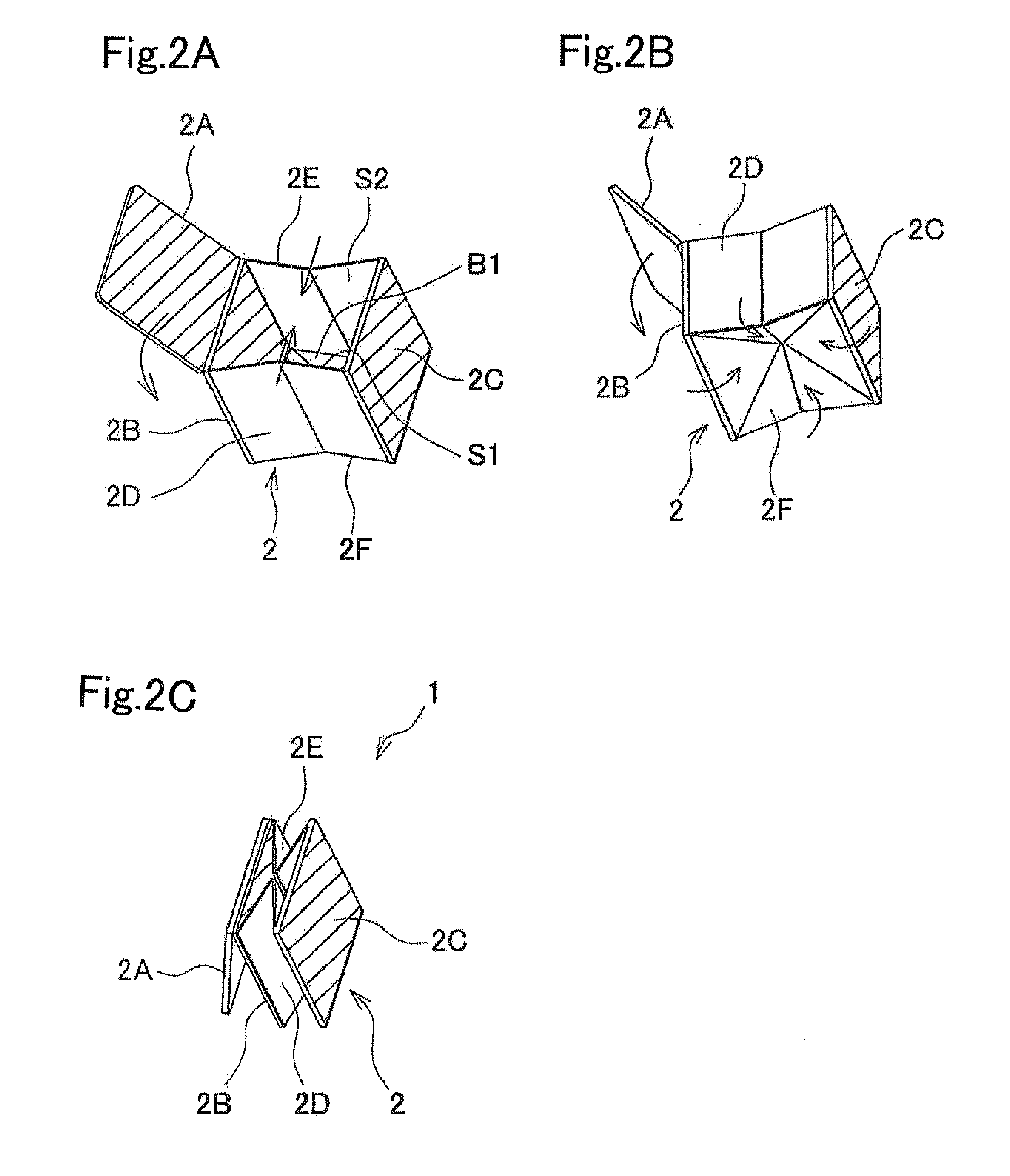

[0039]A first embodiment of the invention is described with reference to FIG. 1A to FIG. 1C and FIG. 2A to FIG. 2C. A tool storage bag 1 shown in FIG. 1A is designed to store therein electric tools such as an impact driver and is formed of a foldable fabric material. The tool storage bag 1 includes a bag body 2 and a stiffener 3.

[0040]The bag body 2 is a hexahedral body having a substantially regular tetragonal bottom and formed by suitably sewing foldable fabric pieces together. A top side 2A of the bag body 2 is sewn to an upper edge of a back side 2B so as to be supported by the back side 2B in a manner to be rotatable about the upper edge in a vertical direction of the bag body 2. That is, the top side can open or close a top side portion of the bag body 2. An electric tool is accommodated in the bag body 2 through an upper opening H thereof. In the bag body 2 of this embodiment, an interlining material is enclosed in the top side 2A, the back side 2B and a front side 2C, respec...

second embodiment

[0047]A second embodiment of the invention is described with reference to FIG. 3. In this embodiment, a similar structure to that of the first embodiment is described briefly. Like reference characters refer to the corresponding components of the first embodiment and the description thereof is dispensed with. A tool storage bag 1A includes a bag body 10 and a stiffener 15. In the tool storage bag 1 of the first embodiment, the flat plates (interlining material) are provided in correspondence to the sides 2A to 2F defining the six sides of the bag body 2. In the tool storage bag 1A of this embodiment, on the other hand, flat plates (a stiffener 15) are provided in correspondence to individual sides 10B, 10D to 10F which define four sides of the bag body 10.

[0048]As shown in FIG. 3A, the bag body 10 is the same hexahedral body as that of the first embodiment. As with the top side 2A of the first embodiment, a top side 10A of the bag body 10 is rotatable in a vertical direction of the ...

third embodiment

[0054]A third embodiment of the invention is described with reference to FIG. 4. In this embodiment, a similar structure to that of the first and second embodiments is briefly described or the description thereof is dispensed with. Like reference characters refer to the corresponding components of the second embodiment and the description thereof is dispensed with. A tool storage bag 1B includes a bag body 20 and the siffener 15. The bag body 20 of the embodiment includes a left side 20D, a right side 20E, a back side 20B and a front side 20C connected together by sewing. A top side 20A of the bag body 20 is fixed to an upper edge of the back side 20B via an upper hinge member 26 so as to be rotatable about the upper edge thereof. A top side portion of the bag body 20 can be opened by rotating the top side 20A toward the back side 20B. A bottom side 20F of the bag body 20 is fixed to a lower edge of the back side 20B via a lower hinge member 27 so as to be rotatable about the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com