Preparation method of functional warm-keeping composite interlining

A functional, flake technology, applied in textiles and papermaking, non-woven fabrics, adhesives, etc., can solve problems such as uneven mixing and the development of functional flakes, and achieve the effect of improving grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

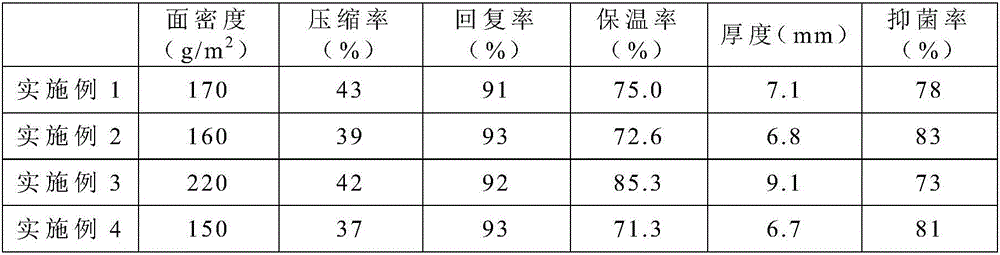

Embodiment 1

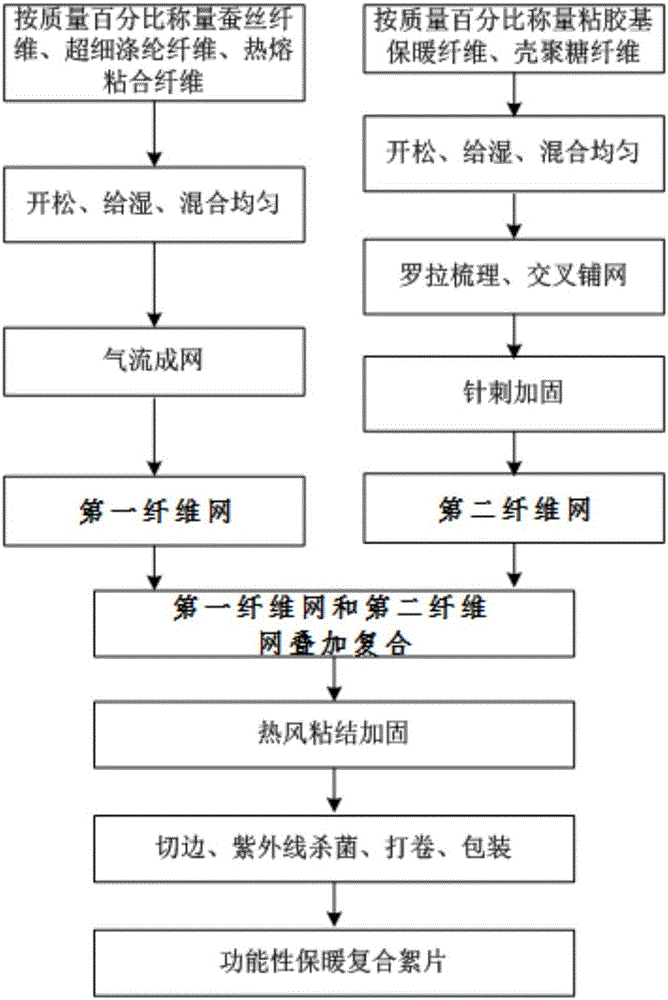

[0024] Embodiment one: see figure 1 Shown, a kind of preparation method of functional thermal insulation composite wadding comprises the following specific steps:

[0025] Step 1) using silk fiber, superfine polyester fiber and hot-melt adhesive fiber as fiber raw materials, wherein the silk fiber is refined dry cotton through scouring, and its fiber length is 38mm; the fineness of the superfine polyester fiber is 0.78dtex and a length of 38mm; the hot-melt adhesive fiber is a low-melting bicomponent composite fiber with a fineness of 1.56dtex and a length of 38mm; according to the mass percentage, it is 80% of silk fiber, 15% of superfine polyester fiber and 5% of hot-melt adhesive fibers, these three kinds of fiber raw materials are weighed, loosened, wetted respectively, and mixed evenly, and then air-laid is used to obtain the first fiber web, and the surface of the first fiber web is The density is controlled at 120g / m 2 ;

[0026] Step 2) Viscose-based thermal insulat...

Embodiment 2

[0029] Embodiment two: see figure 1 Shown, a kind of preparation method of functional thermal insulation composite wadding comprises the following specific steps:

[0030] Step 1) using silk fiber, superfine polyester fiber and hot-melt adhesive fiber as fiber raw materials, wherein the silk fiber is refined dry cotton through scouring, and its fiber length is 38mm; the fineness of the superfine polyester fiber is It is 0.78dtex, and the length is 38mm; the hot-melt adhesive fiber is a low-melting bicomponent composite fiber, and its fineness is 1.56dtex, and the length is 38mm; according to the mass percentage, it is 50% of silk fiber, 35% of superfine polyester fiber and 15% of hot-melt adhesive fibers, these three kinds of fiber raw materials are weighed, loosened, wetted respectively, and mixed evenly, and then air-laid is used to obtain the first fiber web, and the surface of the first fiber web is The density is controlled at 90g / m 2 ;

[0031] Step 2) Viscose-based t...

Embodiment 3

[0034] Embodiment three: see figure 1 Shown, a kind of preparation method of functional thermal insulation composite wadding comprises the following specific steps:

[0035] Step 1) using silk fiber, superfine polyester fiber and hot-melt adhesive fiber as fiber raw materials, wherein the silk fiber is refined dry cotton through scouring, and its fiber length is 38mm; the fineness of the superfine polyester fiber is 0.78dtex and a length of 38mm; the hot-melt adhesive fiber is a low-melting bicomponent composite fiber with a fineness of 1.56dtex and a length of 38mm; according to the mass percentage, it is silk fiber 60%, superfine polyester fiber 30% and 10% of hot-melt adhesive fibers, these three kinds of fiber raw materials were weighed, loosened, wetted, and mixed uniformly, and then air-laid to obtain the first fiber web, and the surface of the first fiber web was The density is controlled at 130g / m2 ;

[0036] Step 2) Viscose-based thermal insulation fiber and chitosa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com