Three-dimensional loop flannelette shell fabric and preparation method thereof

A technology of terry and fabric, which is applied in the field of terry fleece, can solve the problems of easy lodging of loops, influence of fabric appearance and thickness, distortion and deformation, etc., and achieve the effect of increasing thickness and warmth retention, good market prospects, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

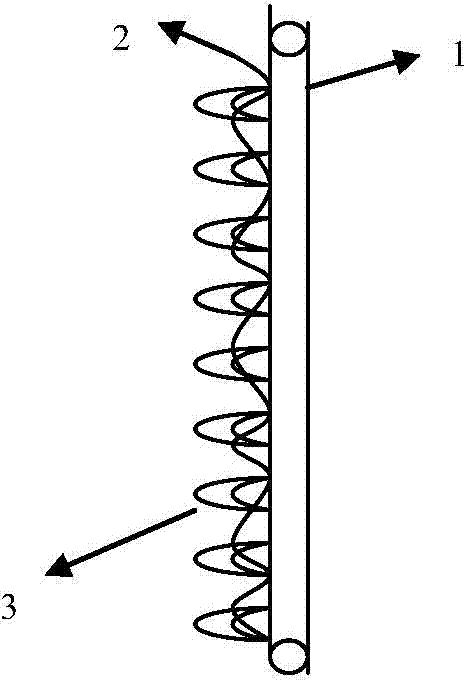

Image

Examples

Embodiment 1

[0029] (1) Select 32S combed cotton, 75D / 36F filament polyester fiber, and 10S polyester-cotton blended yarn (T / C40 / 60) as raw materials;

[0030] (2) Steam the polyester-cotton blended yarn at 120°C for 30 minutes, and the penetrant is 1g / L;

[0031] (3) Knit the plated liner terry structure on the 12G machine number, and the veil, intermediate connecting yarn, and pile yarn of the terry structure are fed into the weft knitting machine through 3F;

[0032] (4) The blank is manufactured with a 16N large circular machine, and then cut and rolled;

[0033] (5) Carry out rubber blanket pre-shrinking finishing on the above rough fabrics, the process conditions are: temperature 100 ° C, overfeed 20%, speed 20 m / min, and the width of the door is flat;

[0034] (5) Finally, carry out dyeing and finishing treatment on the above rough fabric, the process flow is:

[0035] Singeing: open-width singeing on the front and back sides, at a speed of 40 m / min;

[0036] Pre-treatment: caust...

Embodiment 2

[0042] (1) Select 30S combed cotton, 100D / 96F filament polyester fiber, and 8S polyester-cotton blended yarn (T / C40 / 60) as raw materials;

[0043] (2) Steam polyester-cotton blended yarn at 120°C for 45 minutes, penetrant 1g / L;

[0044] (3) Knit the plated liner terry structure on the 12G machine number, and the veil, intermediate connecting yarn, and pile yarn of the terry structure are fed into the weft knitting machine through 3F;

[0045] (4) The blank is manufactured with a 14N large circular machine, and then cut and rolled;

[0046] (5) Carry out rubber blanket pre-shrinking finishing on the above rough fabrics, the process conditions are: temperature 100 ° C, overfeed 20%, speed 20 m / min, and the width of the door is flat;

[0047] (5) Finally, carry out dyeing and finishing treatment on the above rough fabric, the process flow is:

[0048] Singeing: open-width singeing on the front and back sides, at a speed of 70 m / min;

[0049] Pre-treatment: caustic soda 3g / L, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com