Method for preparing sound-absorbing and heat-insulating materials formed by superfine fiber nonwovens

A technology of ultra-fine fiber and non-woven fabrics, applied in the field of non-woven fabrics, can solve the problem of electrospun ultra-fine polyacrylonitrile fiber sound absorption, warmth, heat insulation, which cannot meet the requirements of industrial applications, and the output of electrospinning technology Small and other problems, to achieve the effect of easy industrial implementation, stable and reliable product quality, and good sound absorption and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

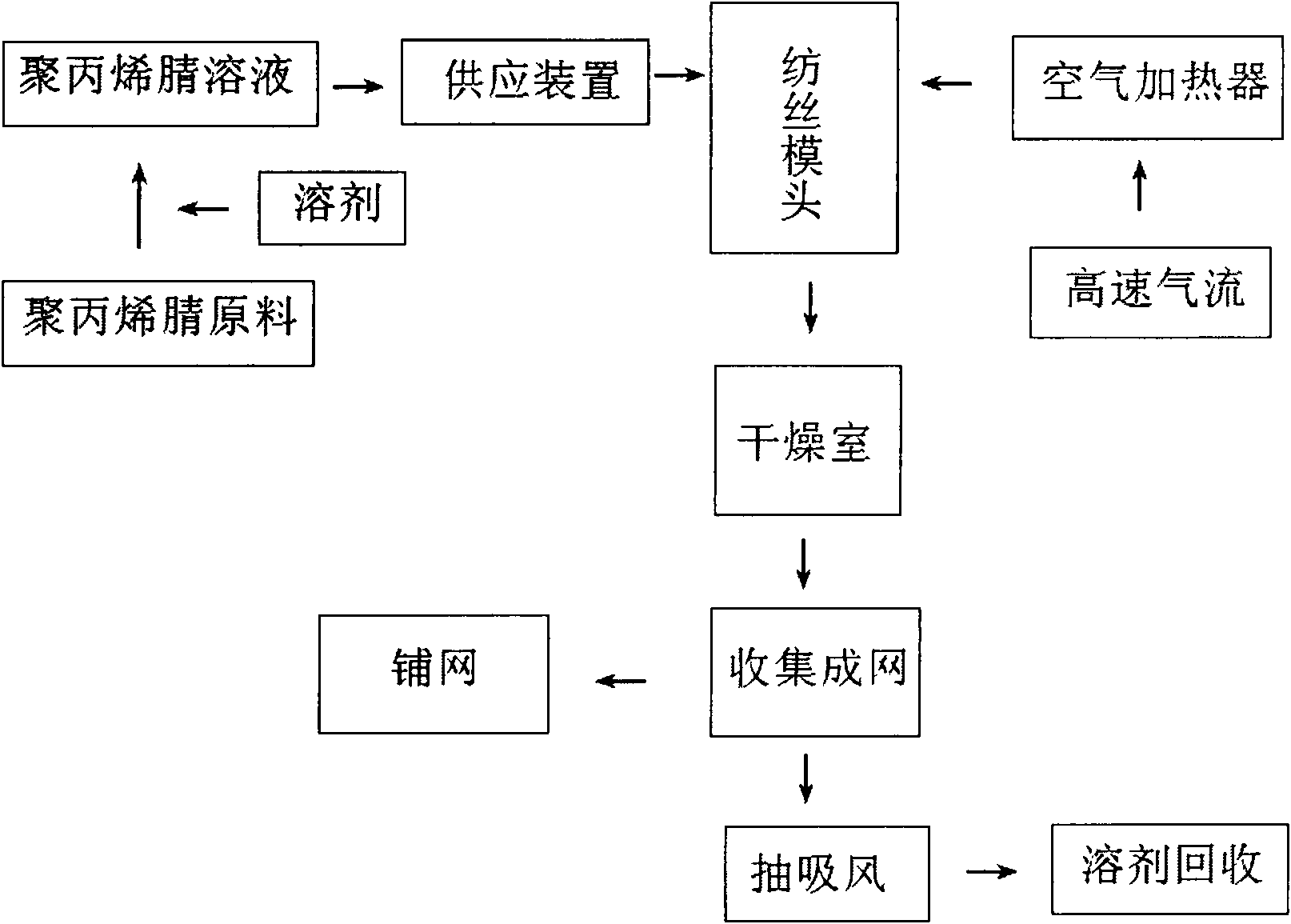

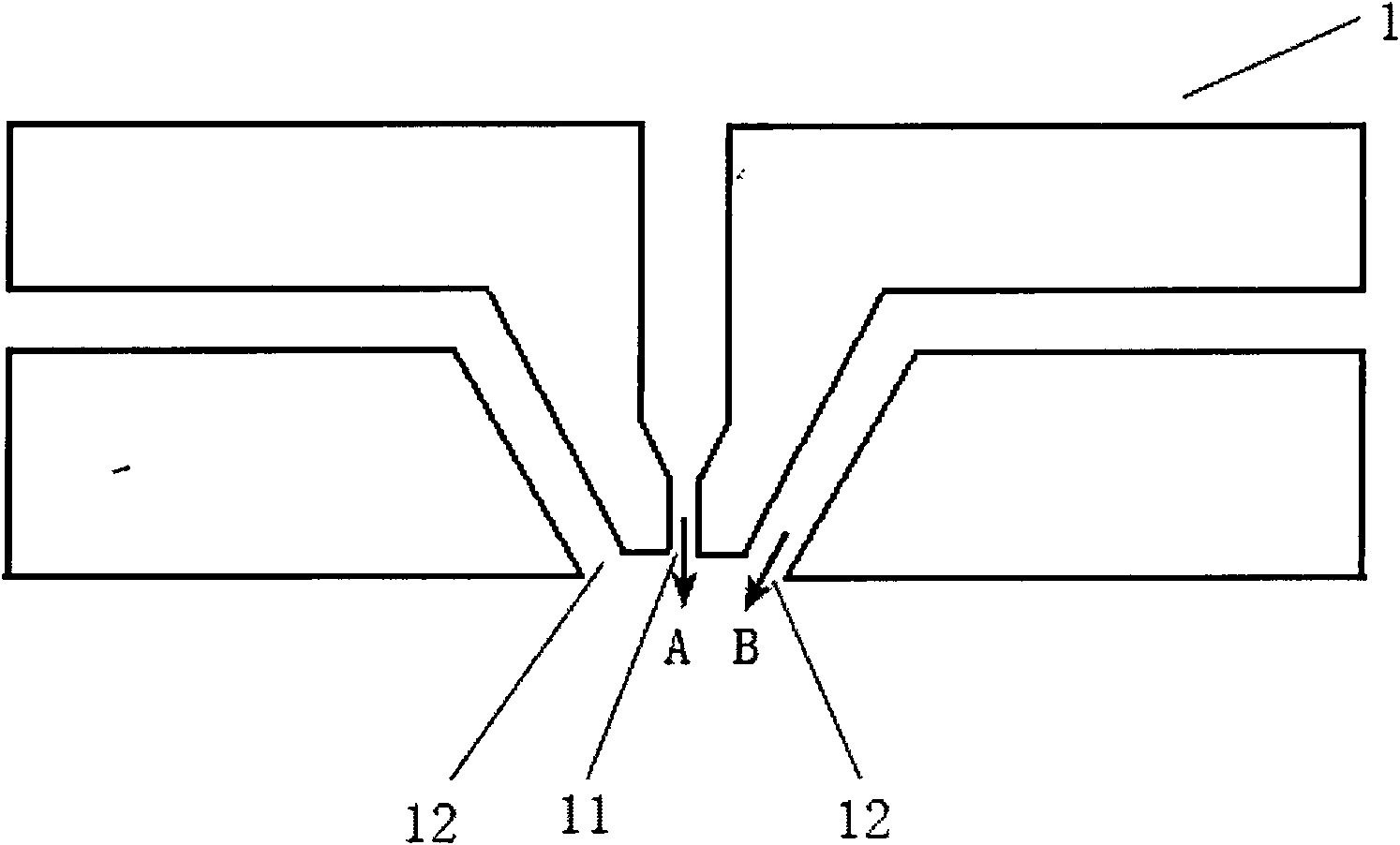

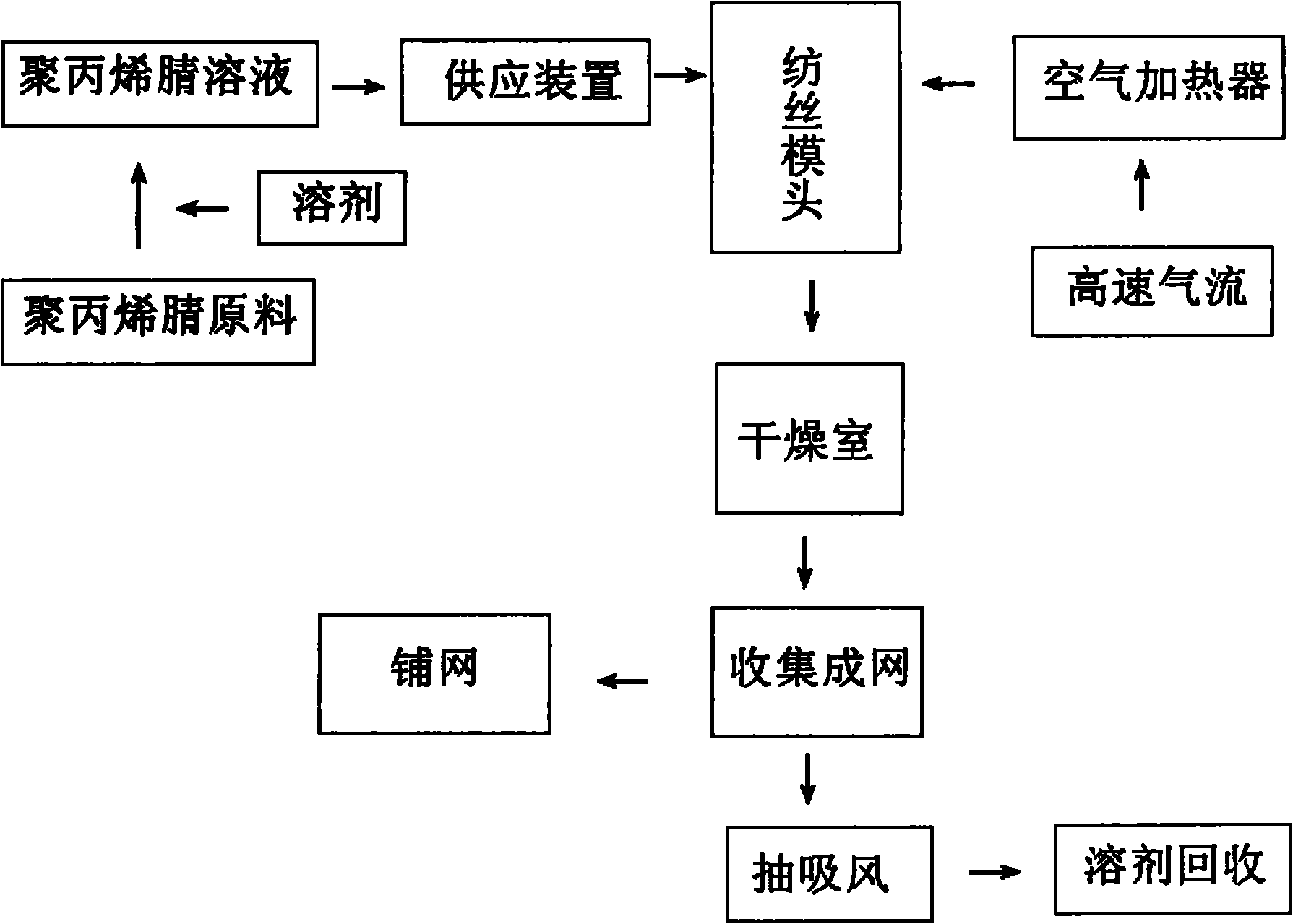

[0014] The preparation method of the superfine fiber nonwoven fabric sound-absorbing and heat-insulating material designed by the present invention (referred to as the preparation method, see figure 1 , 2 ), the process steps are as follows: dissolve polyacrylonitrile in a solvent to form a spinning solution, and then supply the spinning solution to a spinning die 1 containing a series of spinneret holes through a supply device, so that the spinning solution Extrude from the spinning hole 11 of the die 1 to form a fine stream of spinning solution; at the same time, at least one high-speed jet stream heated by an air heater enters the spinning die 1 and passes through the air gap 12 of the spinning die 1 With a spray angle of 15-60 degrees (see attached figure 2 The angle between the A direction and the B direction) is blown toward the extruded spinning solution trickle; the high-speed jet airflow realizes the stretching and refinement of the spinning solution trickle while acce...

Embodiment 1

[0026] Dissolve polyacrylonitrile with a viscosity-average molecular weight of 90,000 into N,N-dimethylformamide in a ratio of 32% by mass, and stir until the mixture is uniform to form a spinning solution; the spinning solution is transported through a metering pump The tube is supplied to the spinning die 1 at a supply rate of 200mL / min and extruded from the spinneret 11; at the same time, a high-speed jet stream with a temperature of 30℃ is ejected from the air gap 12. The wind speed at the outlet of the air gap 12 It is 2400m / min, and the ratio of the jet velocity of the high-speed jet airflow at the outlet to the solution extrusion speed is 2800 times; polyacrylonitrile forms ultrafine fibers in the drying chamber under the action of the high-speed jet airflow, and is collected on the porous mesh curtain. Form a polyacrylonitrile superfine fiber net, export through the net curtain, and cross-lay the net to obtain 80g / m 2 The material of the present invention.

[0027] After ...

Embodiment 2

[0029] Dissolve acrylonitrile-methyl methacrylate copolymer with a viscosity average molecular weight of 150,000 (molar ratio of comonomers 80:20) into N,N-dimethylacetamide at a mass fraction of 25%, and stir until mixed Evenly, make spinning solution. The spinning solution is supplied to the spinneret through a delivery pipe via a metering pump at a supply rate of 120mL / min and extruded from the spinneret 11; at the same time, a high-speed jet air stream with a temperature of 90℃ is ejected from the air gap 12. The wind speed at the outlet of the gap 12 is 6800m / min, and the ratio of the jet velocity of the high-speed jet airflow at the outlet to the solution extrusion speed is about 8000 times; polyacrylonitrile forms ultrafine fibers in the drying chamber under the action of the high-speed jet airflow, and Collected on the porous mesh curtain to form a polyacrylonitrile ultrafine fiber mesh, which is exported through the mesh curtain and cross-laid to obtain 210g / m 2 The ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com