Double component molten and jetted non-woven fabric and its making process

A technology of melt-blown nonwoven fabric and manufacturing method, which is applied in the field of nonwoven fabrics, can solve the problems that the filtration resistance cannot reach high-efficiency filter materials, cannot meet market demands, and has low strength, and achieves good thermal insulation performance, easy control, and hand feeling. soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

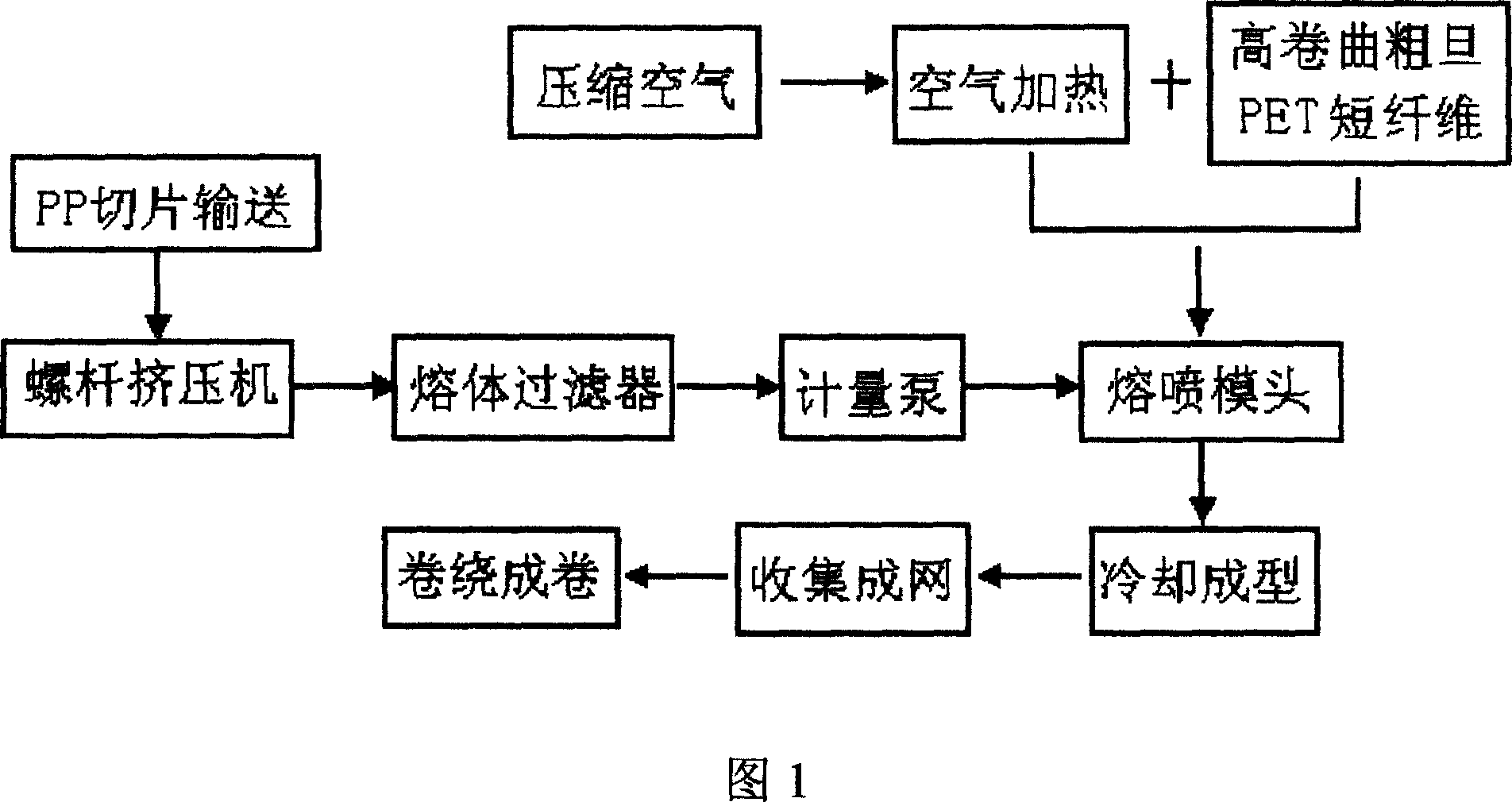

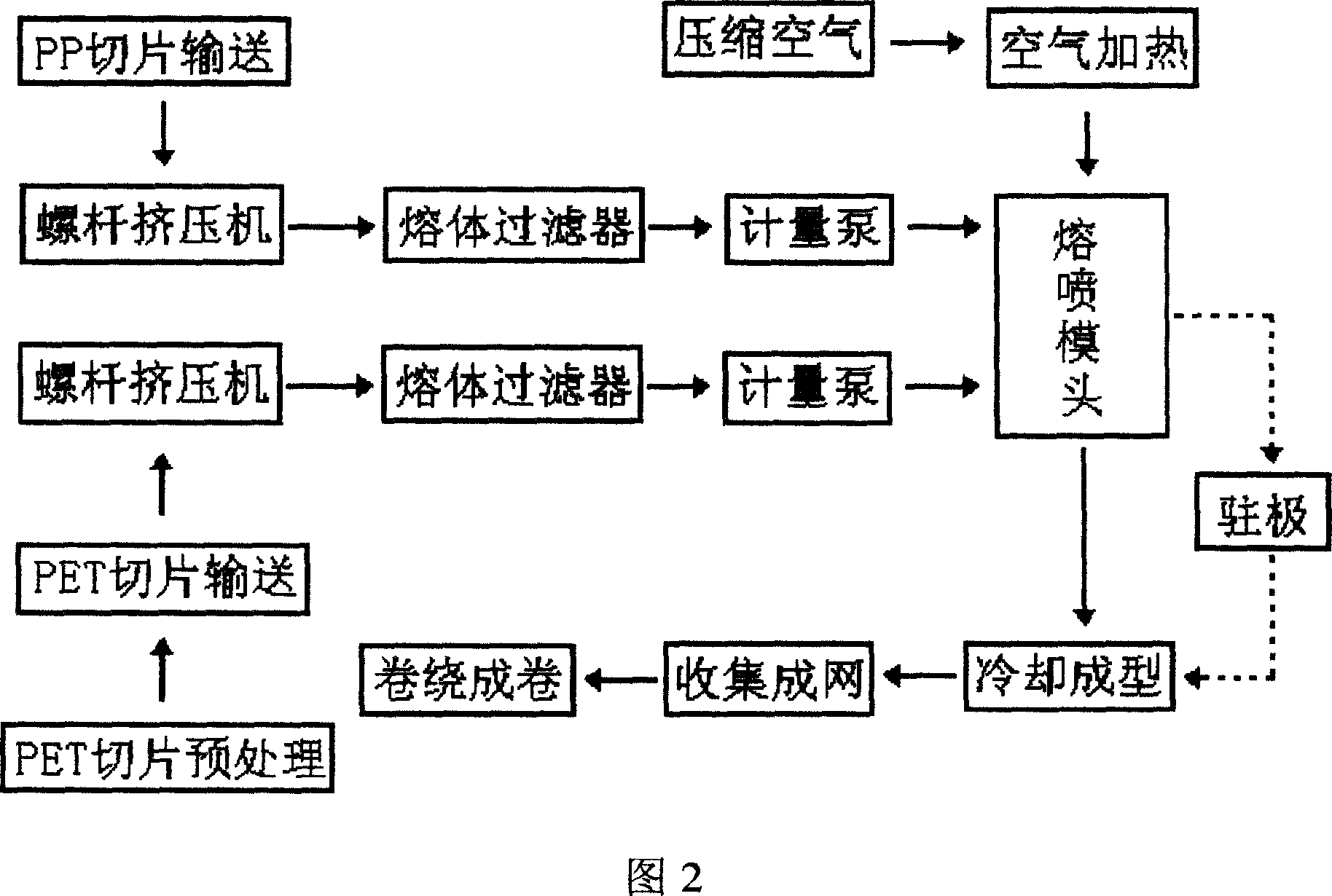

Method used

Image

Examples

Embodiment 1

[0034] (1) Pretreatment: first put the PET component slices into a fluidized bed pre-crystallizer, pre-crystallize at 160°C for 15 minutes, then send them into a filling dryer, and dry at 170°C for 2 hours;

[0035] (2) Manufacture of melt-blown nonwovens: under the protection of nitrogen, feed the pretreated PET component into one of the screw extruders, melt and extrude at 280 ° C, and then pass through the melt filter , metering pump into the melt-blown die head; feed PP directly to another screw extruder, melt and extrude at 230 ° C, and then send it to the same melt-blown die head through a melt filter and a metering pump The two melts meet at the melt-blown die at a ratio of 30 / 70, and can be made into side-by-side two-component melt-blown under the blowing of hot air at 290°C on both sides of the spinneret hole of the melt-blown die. The composite fibers are consolidated into the non-woven fabric by its own waste heat on the receiving device.

[0036] The basis weight ...

Embodiment 2

[0038] (1) Pretreatment: first put the PET component slices into a fluidized bed pre-crystallizer, pre-crystallize at 170°C for 10 minutes, then send them into a filling dryer, and dry at 170°C for 2 hours;

[0039] (2) Manufacture of melt-blown nonwovens: under the protection of nitrogen, feed the pretreated PET component into one of the screw extruders, melt and extrude at 285 ° C, and then pass through the melt filter , The metering pump is sent into the meltblown die head. Feed PP to another screw extruder, melt and extrude it at 235°C, and then send it to the same melt-blown die through a melt filter and a metering pump. The two melts meet at the spinneret at a ratio of 50 / 50, and can be made into side-by-side two-component composite melt-blown fibers under the blowing action of hot air at 300°C on both sides, and are placed on the receiving device by its The non-woven fabric is reinforced by its own waste heat.

[0040] The basis weight of the nonwoven product is 70g / m...

Embodiment 3

[0042] (1) Pretreatment: first put the PET component slices into a fluidized bed pre-crystallizer, pre-crystallize at 170°C for 10 minutes, then send them into a filling dryer, and dry at 170°C for 2 hours;

[0043] (2) Manufacture of melt-blown nonwovens: under the protection of nitrogen, feed the pretreated PET component into one of the screw extruders, melt and extrude at 290 ° C, and then pass through the melt filter , The metering pump is sent into the meltblown die head. Feed PP to another screw extruder, melt and extrude at 240°C, and then send it to the same melt-blown die through a melt filter and a metering pump. The two melts meet at the spinneret at a ratio of 70 / 30, and can form side-by-side two-component melt-blown composite fibers under the blowing action of 300°C hot air on both sides.

[0044] The basis weight of the nonwoven product is 100g / m 2 , fibers with a fineness below 1 μm contain 70%, the average fiber fineness is 0.5 μm, and the fibers are distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com