Fine-denier flat yarn and manufacturing method thereof

A manufacturing method and technology of flat yarn, applied in filament/thread forming, textile and papermaking, melting of filament raw materials, etc., can solve problems such as high fiber flatness, improve internal quality, and improve fiber unevenness rate, to ensure the effect of molding requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

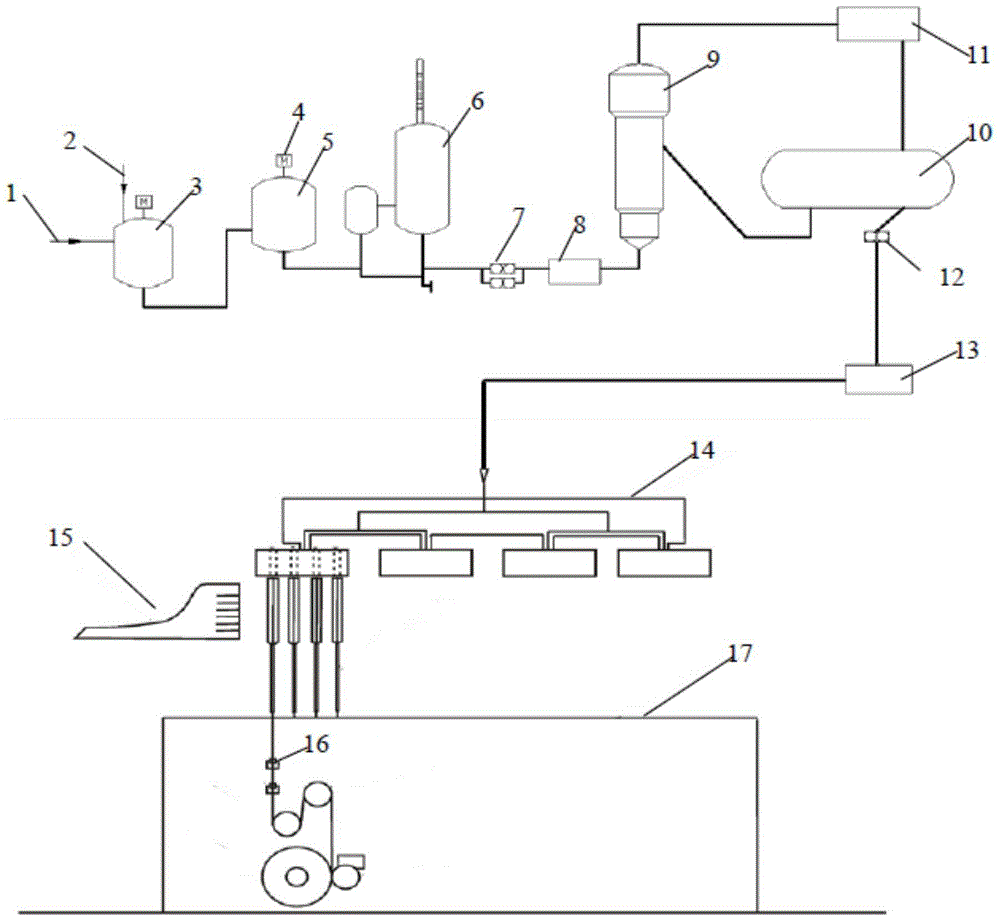

[0016] Such as figure 1 As shown, the fine denier flat yarn described in this embodiment has a monofilament fineness of 0.6-0.9 dtex and a hole number specification of 288.

[0017] The preparation method of fine denier flat silk is as follows:

[0018] (1) Preparation of spinning melt

[0019] Purified terephthalic acid (PTA) and ethylene glycol (EG) enter the slurry preparation tank 3 through the PTA delivery pipeline 1 and the EG delivery pipeline 2 respectively, and then enter the slurry feeding tank 5. Under the action of the motor 4, the The slurry is mixed evenly. After the slurry passes through esterification reactor 6, metering injection pump 7, catalyst feeding device 8, precondensation reactor 9, final polymerization reactor 10 and other equipment, the spinning melt is obtained. The vacuum system device 11 ensures that the pre-polycondensation reaction and the final polycondensation reaction have a suitable vacuum degree. The esterification temperature is 270°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com