Sheet tobacco and method and system for producing same

A technology of tobacco sheets and tobacco, applied in the fields of tobacco, processing tobacco, preparing tobacco, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

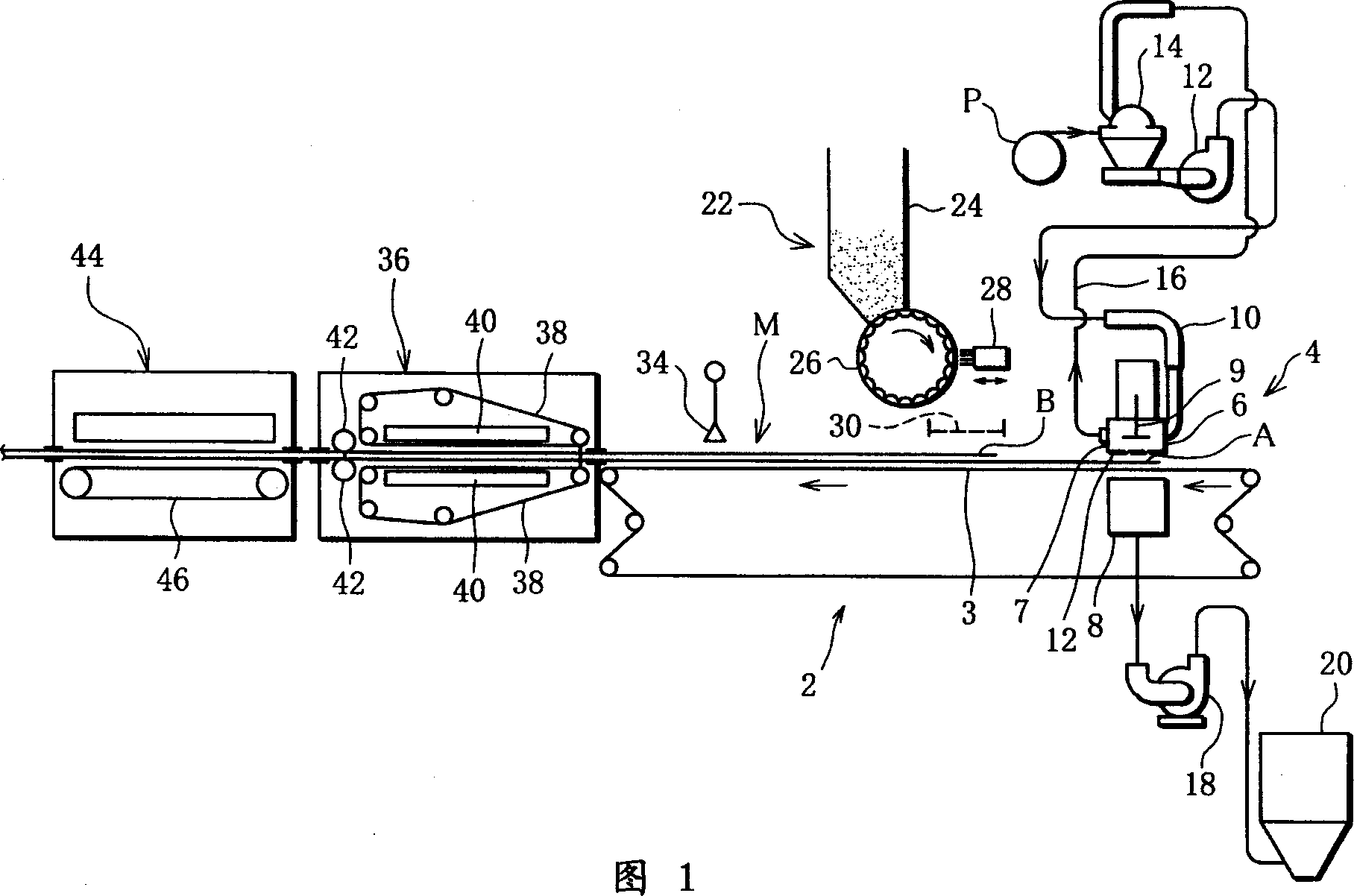

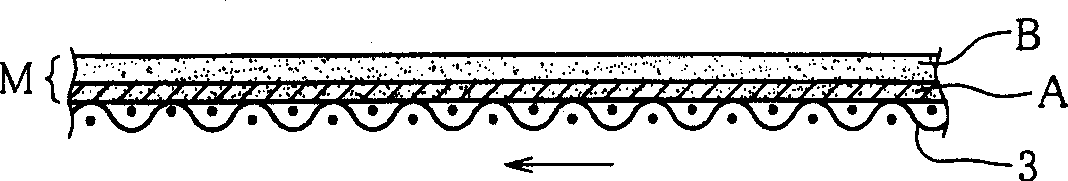

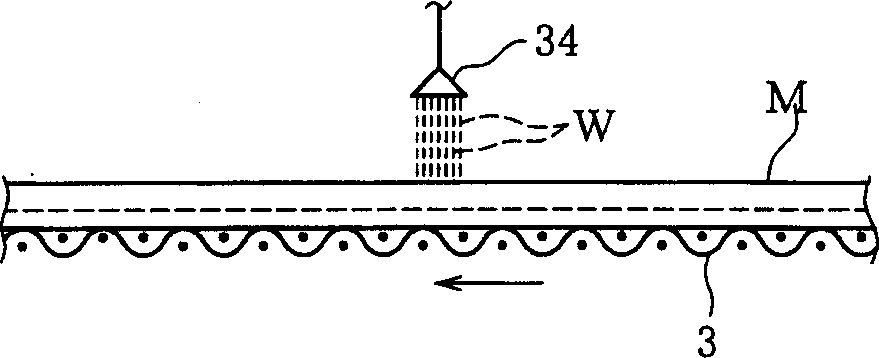

[0063] The manufacturing system of Example 2 has two slurry laminators 4 , and a powder disperser 22 is disposed between these laminators 4 . According to this manufacturing system, a cover sheet C is also formed on the bottom plate M, that is, the tobacco powder layer B. As shown in FIG. The cover sheet C is the same slurry laminated sheet as the carrier sheet A. Therefore, when the bottom plate M passes through the downstream laminator 4, as Figure 8 and Figure 9 As shown, the bottom plate M forms a three-layer structure, and the tobacco powder layer B is sandwiched between the holding sheet A and the cover sheet C.

[0064] In the case of the bottom plate M with a three-layer structure, the weight of each of the holding sheet A and the cover sheet C is 3 to 50 g / m 2 eg 9g / m 2 , the level of tobacco powder layer B is 30 ~ 200g / m 2 For example 132g / m 2 . The weight ratio of binder powder to tobacco leaf powder in the mixed powder is 10 to 90. The arrangement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com